Thin film deposition method and thin film deposition equipment

A thin film deposition and equipment technology, applied in the field of thin film deposition methods and equipment, can solve the problems affecting the electrical properties and other physical properties of the phase change material film, the quality of the phase change material film is not high, and the performance of the phase change memory, so as to promote Effects of target sputtering reaction, concentration reduction, and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

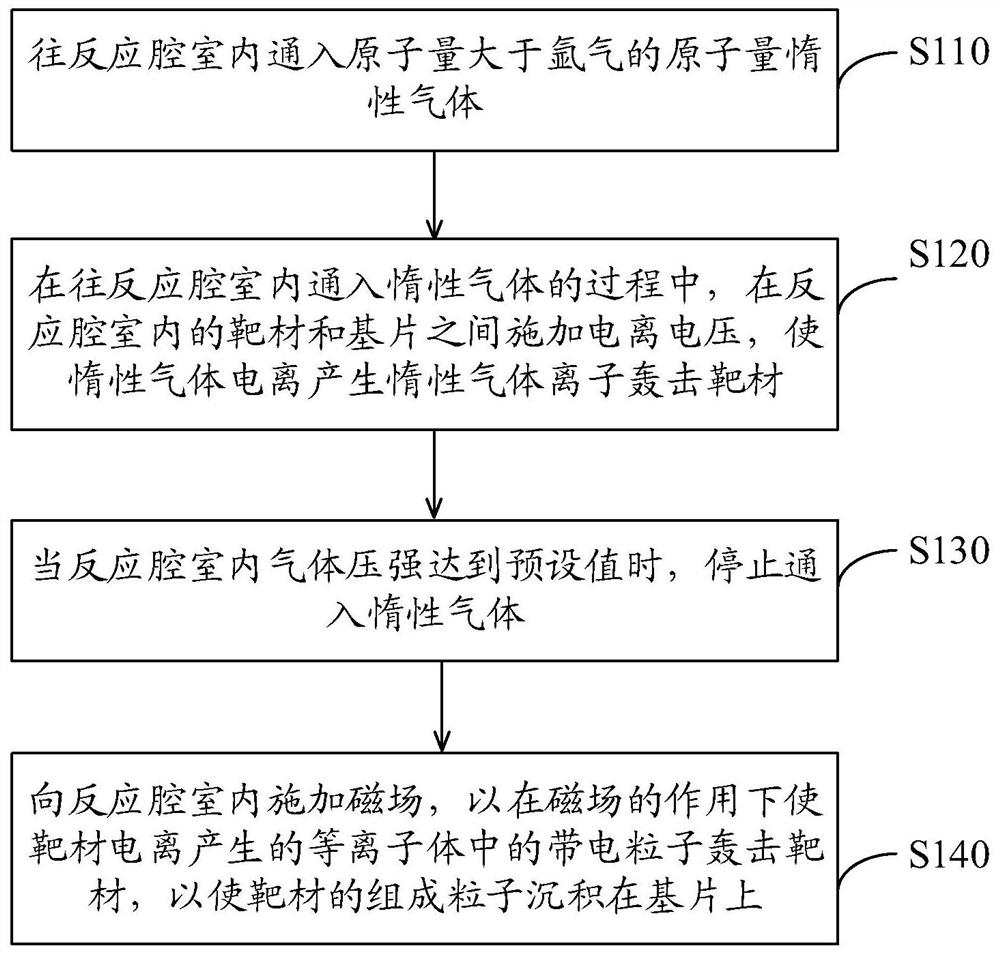

[0044] The technical solutions of the present disclosure will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0045] In the embodiments of the present disclosure, terms such as "first" and "second" are used to distinguish similar objects, and are not used to describe a specific sequence or sequence.

[0046] In the embodiments of the present disclosure, the term "A is in contact with B" includes a situation where A is in direct contact with B, or a situation where A is indirectly in contact with B with other components interposed between A and B.

[0047] In embodiments of the present disclosure, the term "layer" refers to a portion of material comprising a region having a thickness. A layer may extend over the entirety of the underlying or overlying structure, or may have an extent that is less than the extent of the underlying or overlying structure. Furthermore, a layer may be a region of homogeneous or heterog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com