Device for treating polyester beverage bottle recycling sewage

A sewage treatment device and beverage bottle technology, which is applied in the directions of flocculation/sedimentation water/sewage treatment, dehydration/drying/concentrated sludge treatment, filtration and separation, etc., which can solve difficult to meet, secondary pollution of the environment, large number of workers, etc. problems, to achieve the effect of reducing operational risks, reducing labor intensity, and meeting development requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

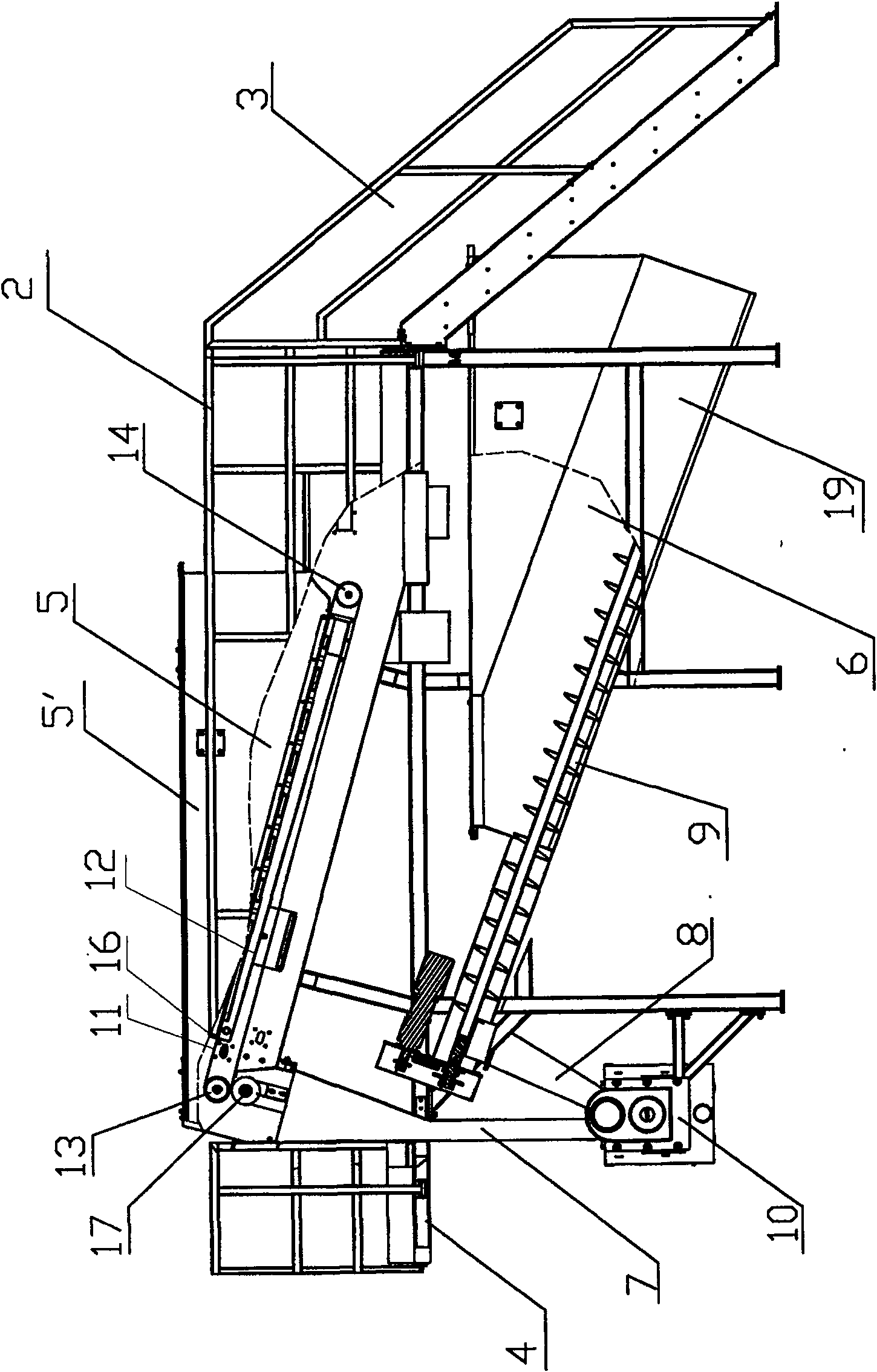

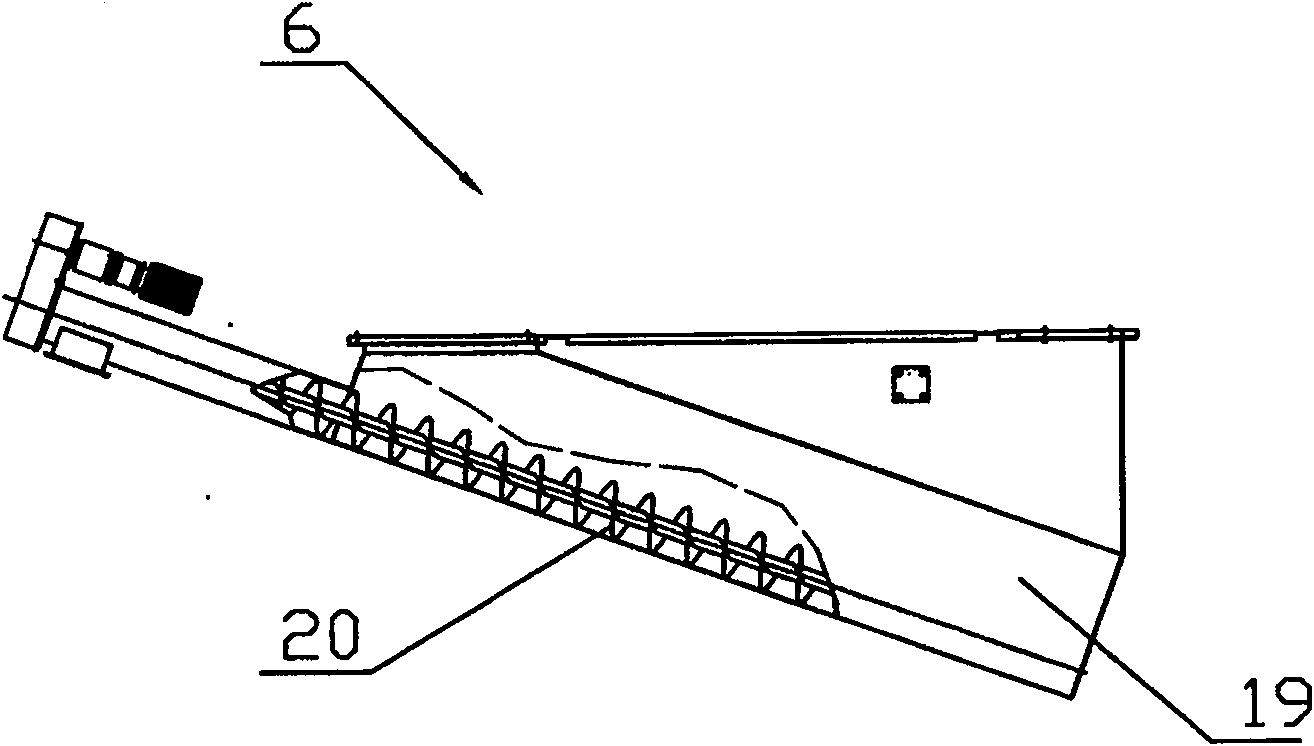

[0026] Embodiment 1: the polyester beverage bottle of the present embodiment reuses sewage treatment plant, as figure 1 As shown, it includes a frame 1, a working platform 4 installed on the frame 1, guardrails 2 are installed on both sides of the working platform 4, the working platform 4 is connected to the stairs 3, a filter device 5 is installed on the frame 1, and one end of the filter device 5 A sedimentation device 6 is installed below, and the other end of the filter device 5 is connected to the sludge collection tank 7. A conveying twisted cage 9 is installed in the sedimentation device 6, and one end of the conveying twisted cage 9 is connected with a sludge collection tank 8, two sludge collection tanks 7, 8 are all connected with the sludge press 10.

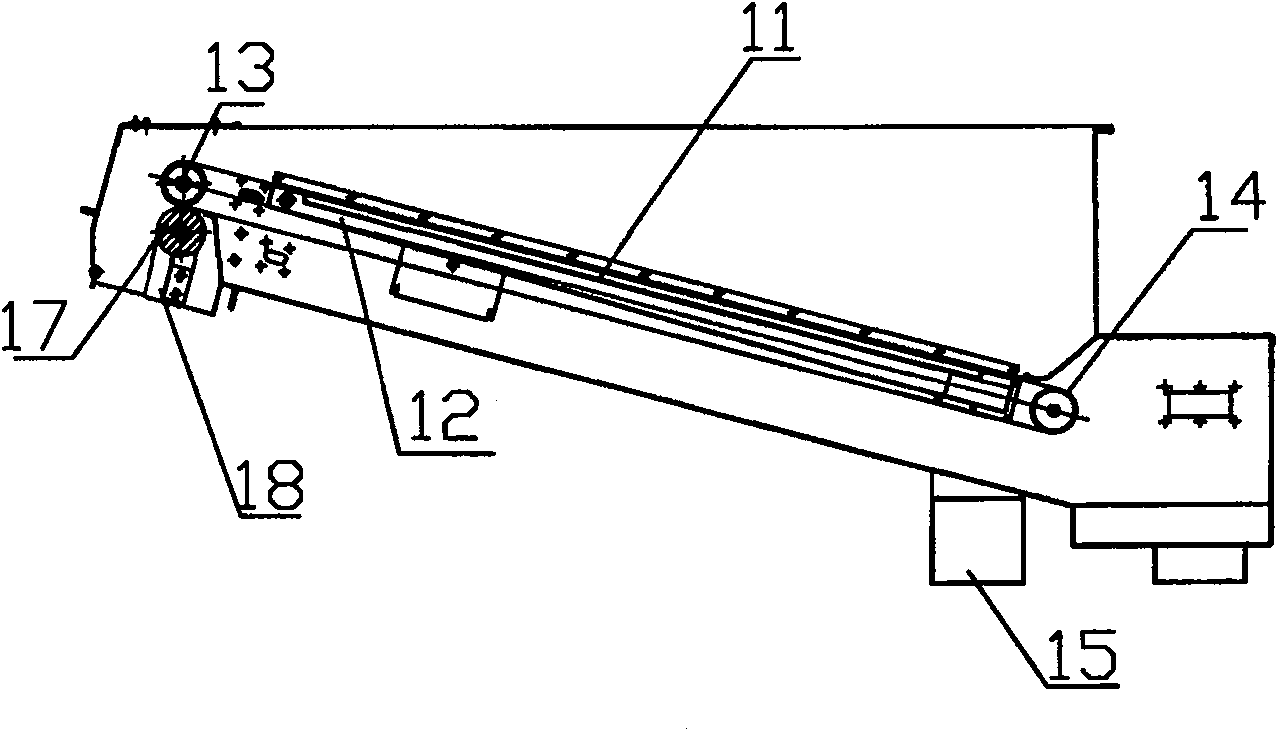

[0027] Such as figure 2 As shown, the filter device 5 includes a filter box 5' with a filter screen 11 built in. The filter screen 11 is fixed by a filter screen bracket 12 and driven by a filter screen driving dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com