Photo-etching illumination system

A lighting system and lithography technology, applied in the field of microlithography, can solve the problems of reducing the transmittance of the lighting system, increasing the complexity of the system structure, etc., and achieve the effects of continuously adjustable lighting coherence, avoiding energy loss, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The lithography illumination system of the present invention will be further described in detail below, and the "axis" referred to in the following all refers to the direction along the optical axis.

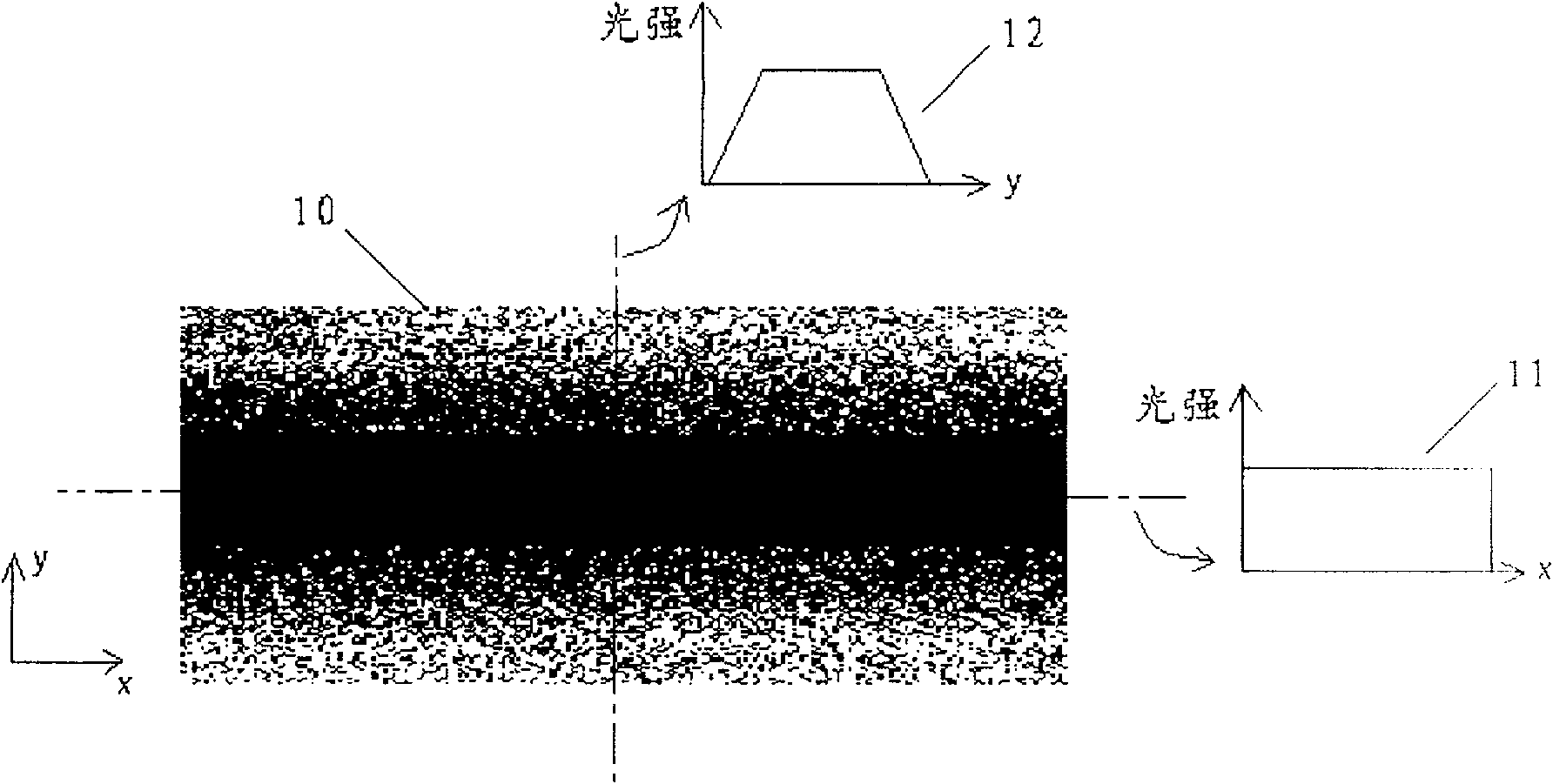

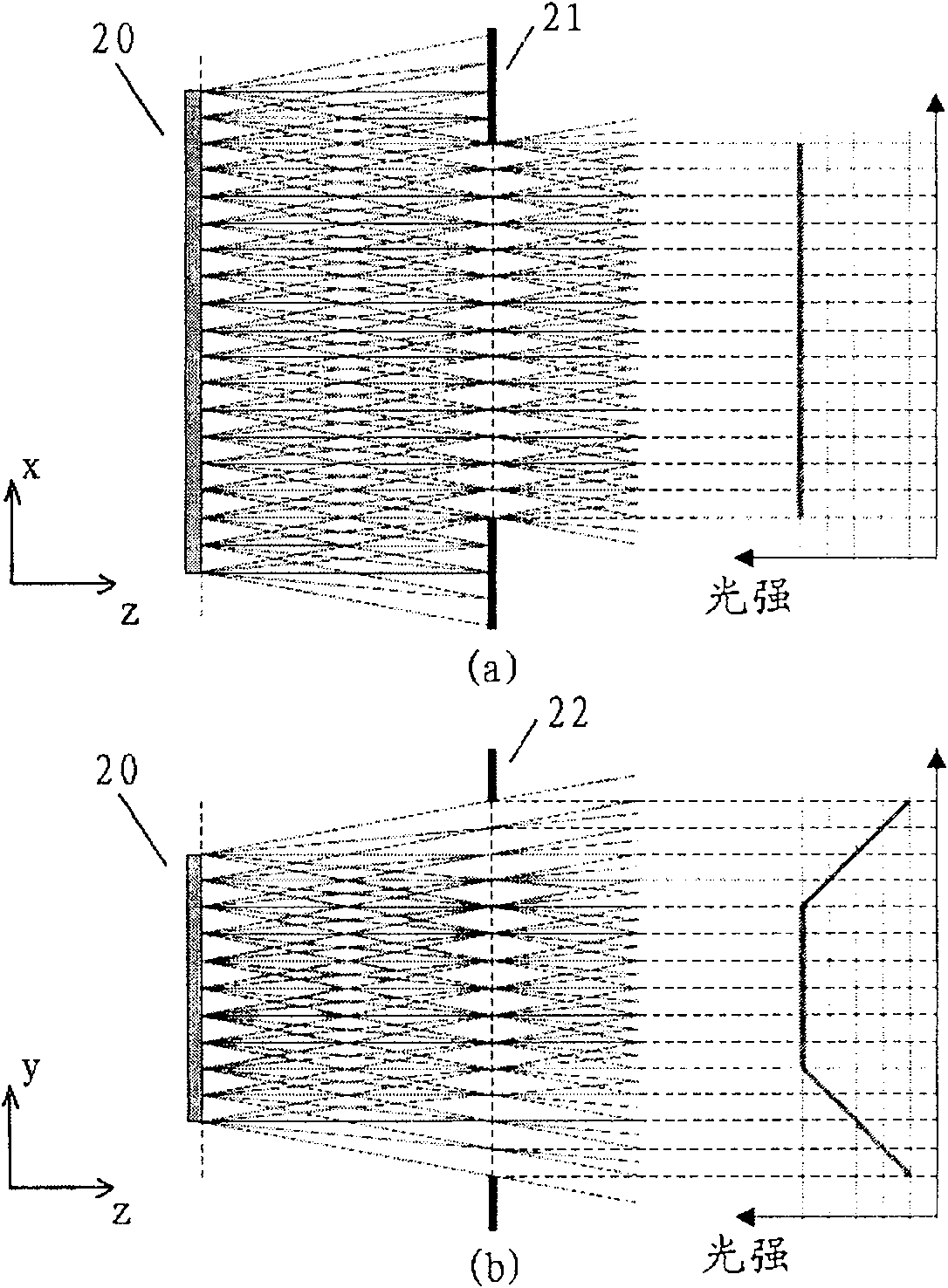

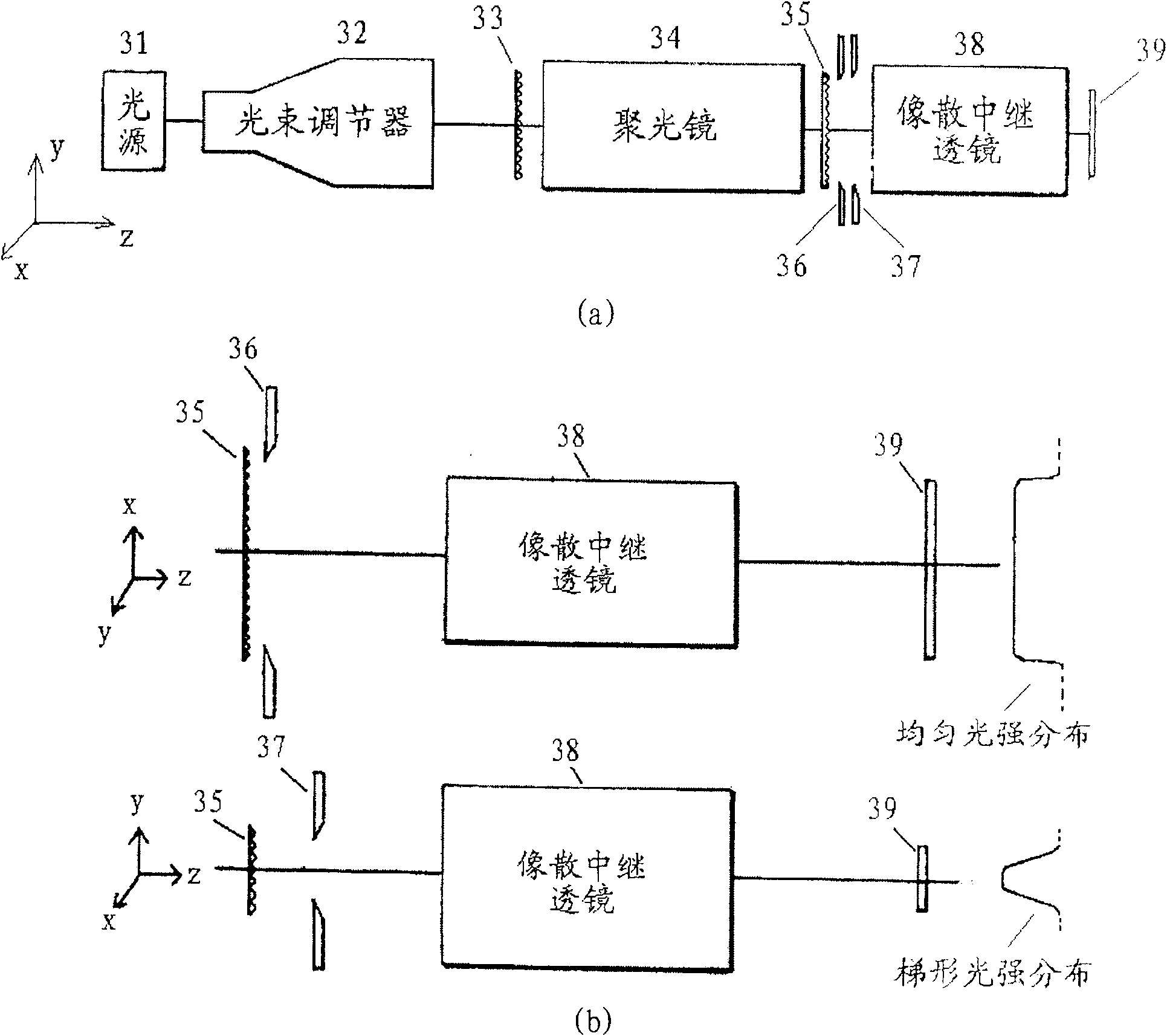

[0048] Such as Figure 4 As shown, the lithography illumination system of the present invention includes in turn from the object side to the image side: a light source 100 for generating an illumination beam of a specific wavelength, such as: 248nm, 193nm, 157nm, 126nm, etc.; a pupil shaping module 200 for receiving The illumination beam from the light source 100 forms an illumination beam with a specific cross-sectional shape; the microlens array module 300 receives the illumination beam from the pupil shaping module 200 and forms an illumination beam with a one-dimensional trapezoidal light intensity distribution; and the condenser lens 400, The illuminating light beam from the microlens array module 300 is received, and the condensed illuminating light beam is projecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com