Heated air circulation heating device of oil storage vessel

A technology of hot air circulation and hot air heating, which is used in heat storage heaters, air heaters, fluid heaters, etc., can solve the problems of slow heating of the heat medium, inability to meet the needs of heating oil storage tanks, and inability to rise. achieve high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

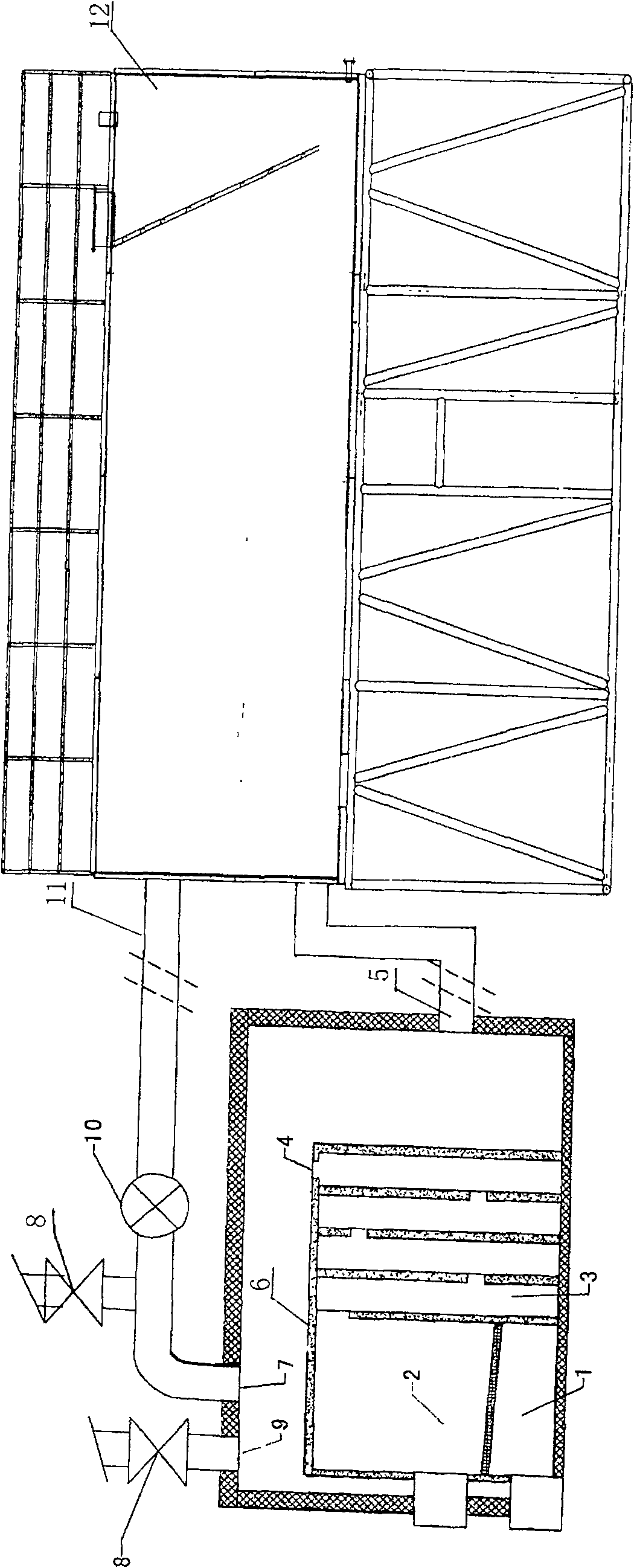

[0012] In order to further disclose the technical solution of the present invention, below in conjunction with the accompanying drawings, the following examples are described in detail:

[0013] The invention consists of a coal-fired hot air heating furnace, a hot air circulation coil 11 and an oil storage tank 12, and is characterized in that the air outlet of the coal-fired hot air heating furnace is connected to the inlet of the hot air circulation coil of the oil storage tank through a hot air pipe and an induced draft fan , the outlet of the hot air circulation coil is connected with the air return port of the coal-fired hot air heating furnace.

[0014] When applying the present invention, at first open the flue gas regulating valve 8, start the stove, coal ash falls into the ash storage chamber 1, the flame of the combustion chamber 2 and the flue gas pass through the labyrinth exhaust flue 3, and the flue dust is filtered layer by layer, Regularly remove or backwash. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com