Waveguide inflator

An inflator and waveguide technology, which is applied in the direction of electrical components, antennas, circuits, etc., can solve the problems of large air humidity difference and inconvenience of waveguide inflators, etc., and achieve the effect of simple structure, good use effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

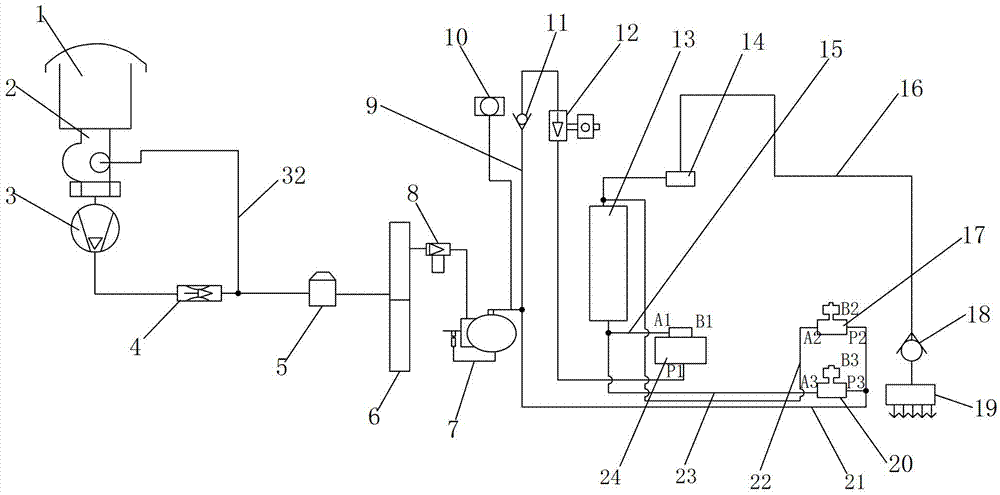

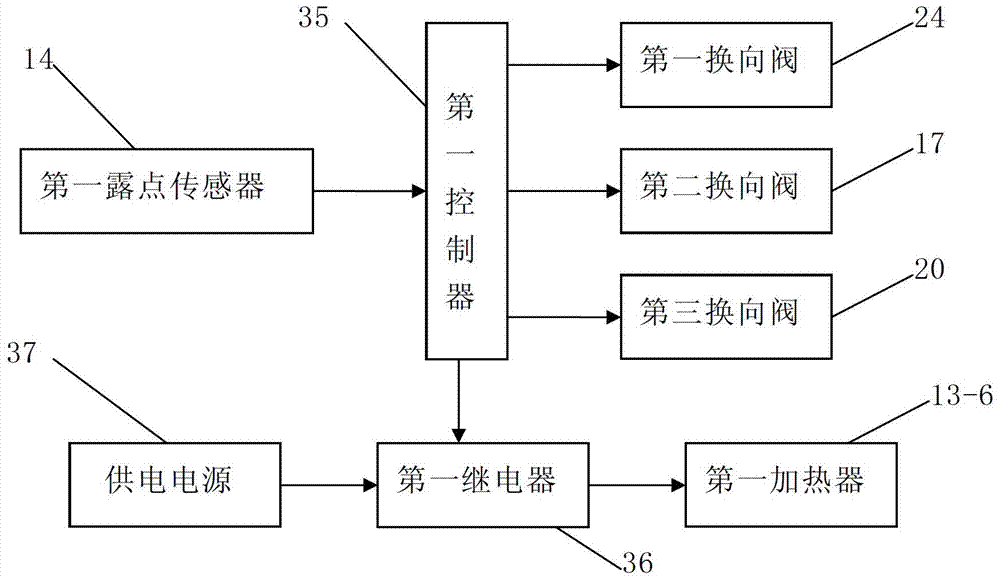

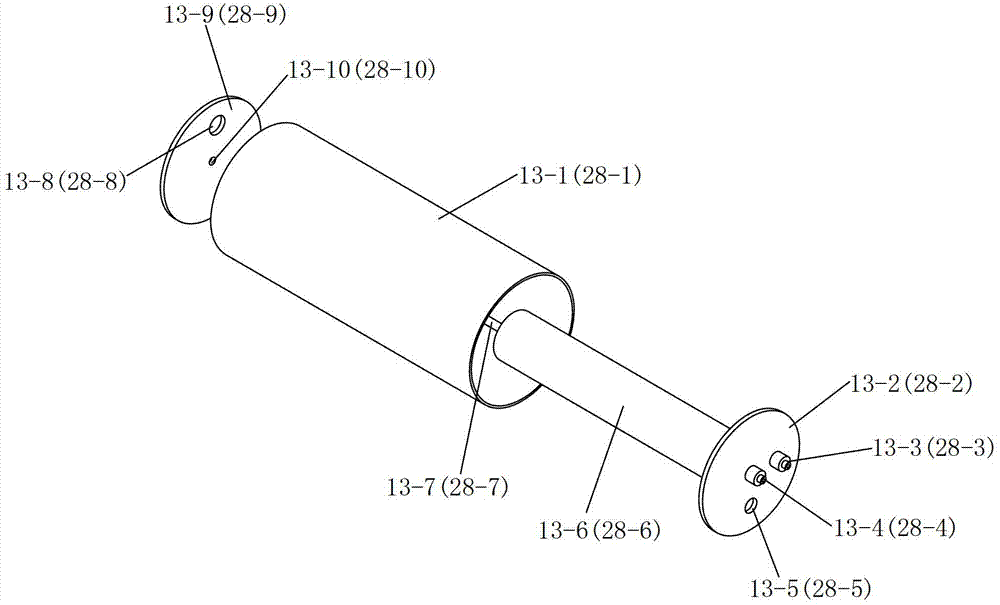

[0031] Such as figure 1 and image 3 The shown waveguide inflator includes an air intake valve 2, an air compressor 3, a first drying cylinder 13, and a first reversing valve 24, a second reversing valve 17 and a third reversing valve, all of which are two-position reversing valves. Reversing valve 20; the first drying cylinder 13 is filled with air desiccant, the first drying cylinder 13 is provided with a first heater 13-6, and one end of the first drying cylinder 13 is provided with a first Gas input port 13-5, the other end of the first drying cylinder 13 is provided with a first gas output port 13-8; the inlet valve 2 is connected to the input port of the air compressor 3, and the air compressor 3 The output port of the first reversing valve 24 is connected to the first gas port P1 of the first reversing valve 24 through the first gas delivery pipe 9, and the second gas port A1 of the first reversing valve 24 is connected to the first gas input port 13- 5 connection, th...

Embodiment 2

[0038] Such as image 3 and Figure 4 As shown, the only difference between this embodiment and Embodiment 1 is: the waveguide inflator also includes a second drying cylinder 28, the second drying cylinder 28 is filled with air desiccant, and the second drying cylinder 28 A second heater 28-6 is arranged inside, one end of the second drying cylinder 28 is provided with a second gas input port 28-5, and the other end of the second drying cylinder 28 is provided with a second gas output port 28- 8; The third gas port B1 of the first reversing valve 24 is connected with the second gas input port 28-5 through the seventh gas delivery pipe 31, the third gas delivery pipe 16 is connected with a shuttle valve 25, the second The gas output port 28-8 is connected to the shuttle valve 25 through the eighth gas delivery pipe 26, the first gas port P3 of the third reversing valve 20 is connected to the fourth gas delivery pipe 21, and the third reversing valve 20 The second gas port A3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com