Complex enzyme degumming method for jute or mesot

A degumming method and compound enzyme technology, applied in textiles and papermaking, fiber treatment, biochemical fiber treatment, etc., can solve the problems of large difference in active pH value and cumbersome steps, etc., and achieve short processing time, simple steps and high reliability. spinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

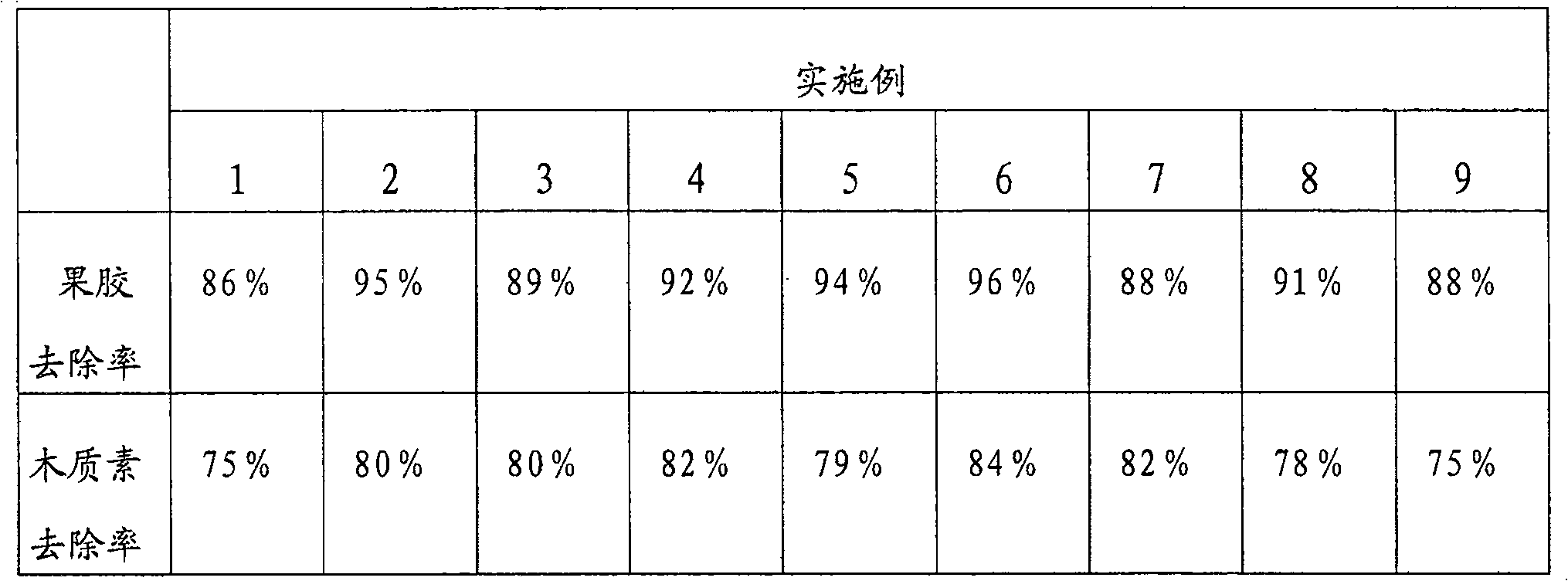

Examples

Embodiment 1

[0018] Unpack the jute or kenaf purchased from the market, and divide them into small handfuls of about 0.5 kg; perform pretreatment in a water bath, the temperature of the water bath is 65°C, and the holding time is 2 hours; acid pectinase and lacquer The enzyme is formulated into a compound enzyme at a weight ratio of 3:7, and the compound enzyme prepared is taken at a weight ratio of 0.5:100 to jute or kenaf, and diluted with water to 12 times the weight of jute or kenaf, and then diluted with the compound enzyme aqueous solution Dipping of jute or kenaf;

[0019] Adjust the pH value of the above diluted solution to 4.5 with acetic acid, raise the temperature to 35°C, and keep it for 50 minutes; then take jute or kenaf out of the solution and pile it up for synergistic stacking treatment, synergistic stacking treatment The time is 24 hours;

[0020] The jute or kenaf after the synergistic stacking treatment is washed with hot water at 80°C for enzyme inactivation treatment...

Embodiment 2

[0023] Unpack the jute or kenaf purchased from the market, divide it into small handfuls of about 0.5 kg, and carry out acid bath and water bath pretreatment. The acid used is concentrated sulfuric acid with a concentration of more than 90%. The temperature of the water bath is 30°C, holding time is 1 hour;

[0024] Acid pectinase and laccase are prepared into a composite enzyme in a weight ratio of 9:1, and the configured composite enzyme is taken in a weight ratio of 5:100 with jute or kenaf, and diluted with water to 40 times the weight of jute or kenaf, Dipping jute or kenaf with diluted complex enzyme aqueous solution;

[0025] Adjust the pH value of the above diluted solution to 6.0 with acetic acid, raise the temperature to 55°C, and keep it for 100 minutes; then take the jute or kenaf out of the solution and pile it up for synergistic stacking treatment, synergistic stacking treatment The time is 12 hours;

[0026] The jute or kenaf after the synergistic stacking tre...

Embodiment 3

[0029] The jute or kenaf purchased from the market is unpacked, divided into small handfuls of about 0.5 kg, and the jute or kenaf is pretreated in an acid bath, and the acid used is acetic acid with a concentration of more than 90%. Acid pectinase and laccase are prepared into a composite enzyme in a weight ratio of 1:1, and the configured composite enzyme is taken in a weight ratio of 1:100 with jute or kenaf, and diluted with water to 20 times the weight of jute or kenaf, Dipping jute or kenaf with diluted complex enzyme aqueous solution;

[0030] Adjust the pH value of the above diluted solution to 5.0 with acetic acid, raise the temperature to 40°C, and keep it for 120 minutes; then take jute or kenaf out of the solution and pile it up for synergistic stacking treatment, synergistic stacking treatment Time is 10 hours;

[0031] The jute or kenaf after the synergistic stacking treatment is washed with hot water at 75°C to perform enzyme inactivation treatment, and the deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com