Contactor

A contactor and negative connection technology, applied in relays, electromagnetic relays, electrical components, etc., can solve the problems of AC contactor structure, power consumption and cost that are not well improved, and achieve simple structure, stable performance, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

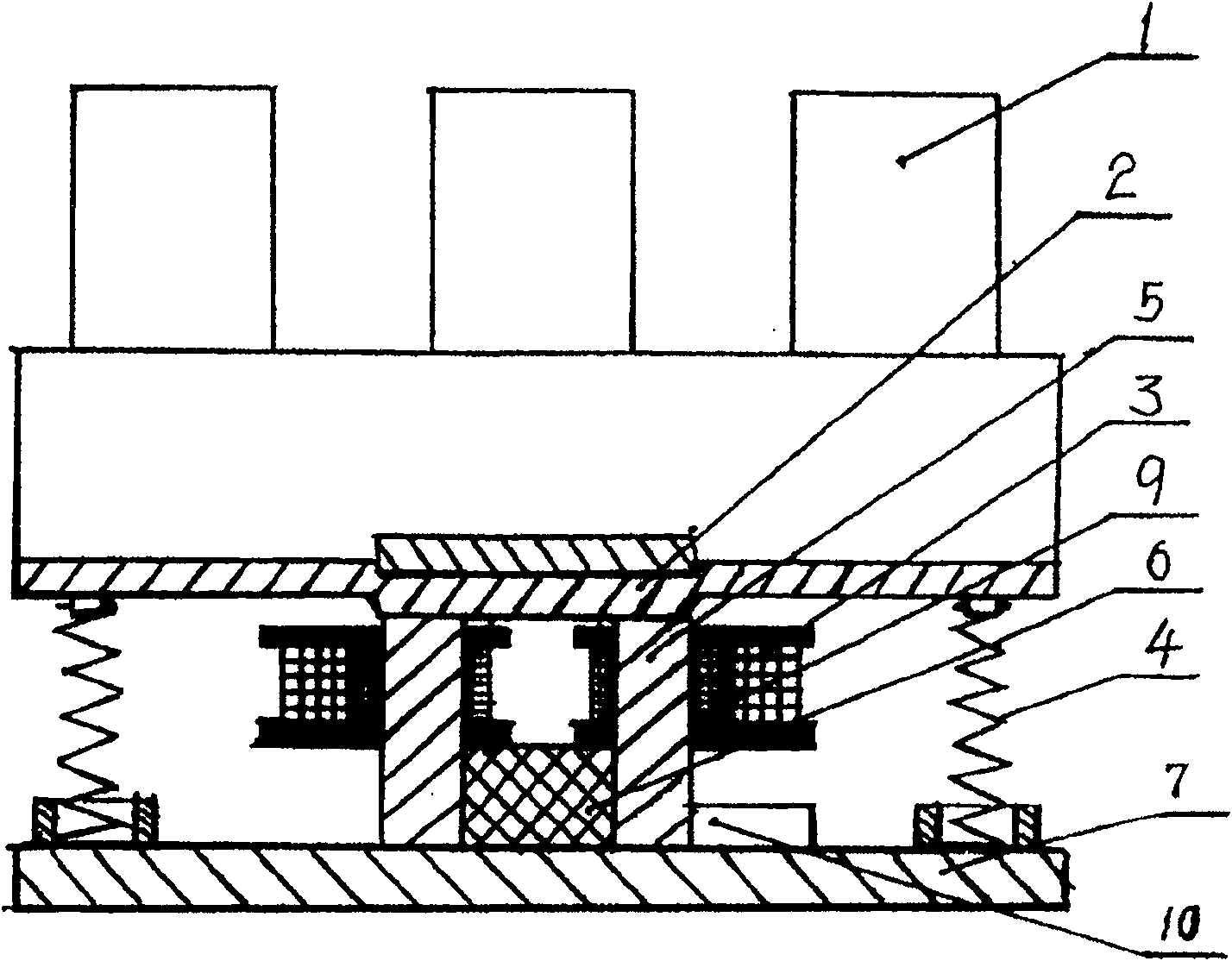

[0029] figure 1 It is a schematic diagram of the structure of the constant magnetic holding AC contactor in the prior art. In the figure, 1 is the main body, 2 is the upper moving iron core, 3 is the electromagnetic pull-in coil, 4 is the spring, 5 is the lower static iron core, and 6 is the permanent magnet. , 7 is the base, 9 is the anti-magnetic coil, and 10 is the capacitor releaser. This contactor uses four coils with reference numeral 3 and one coil with reference numeral 9, that is, 5 coils are used in total.

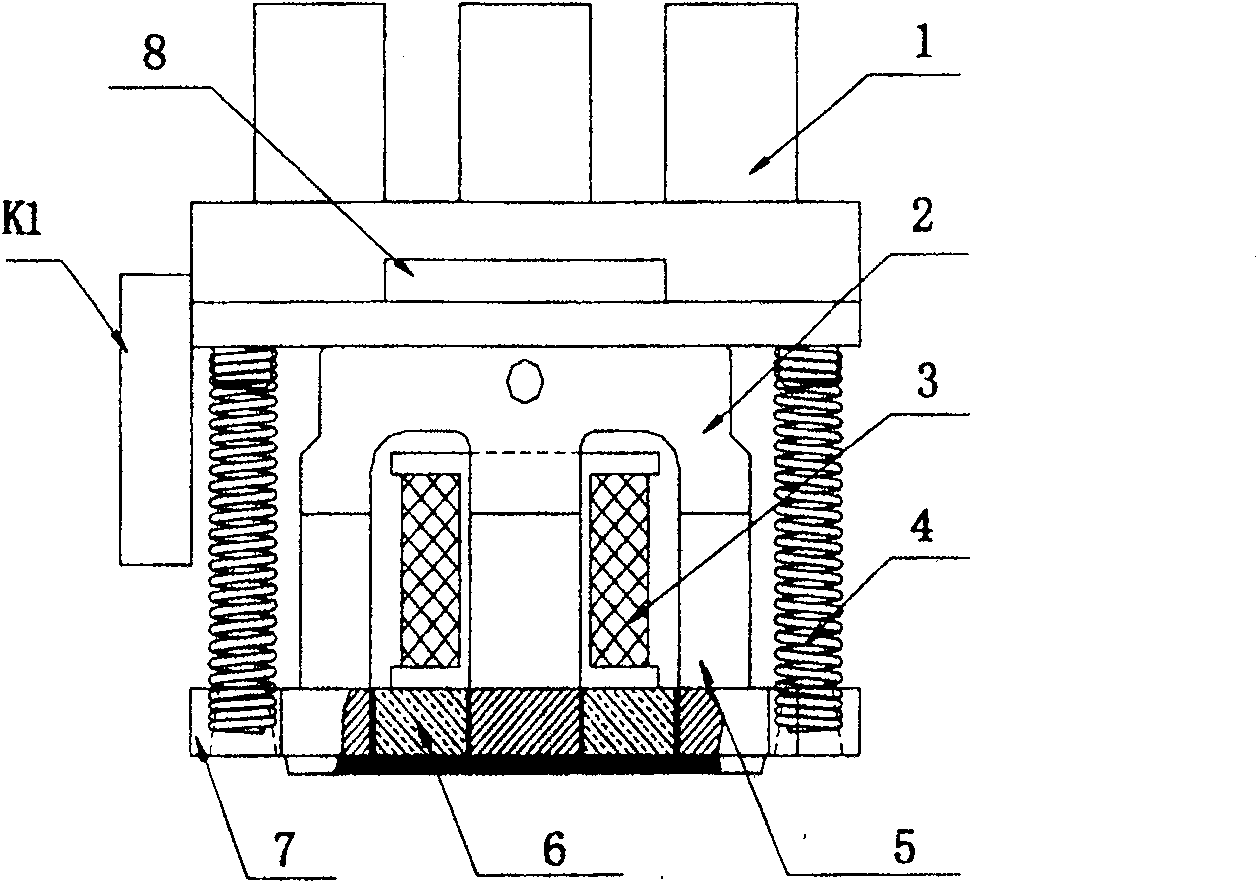

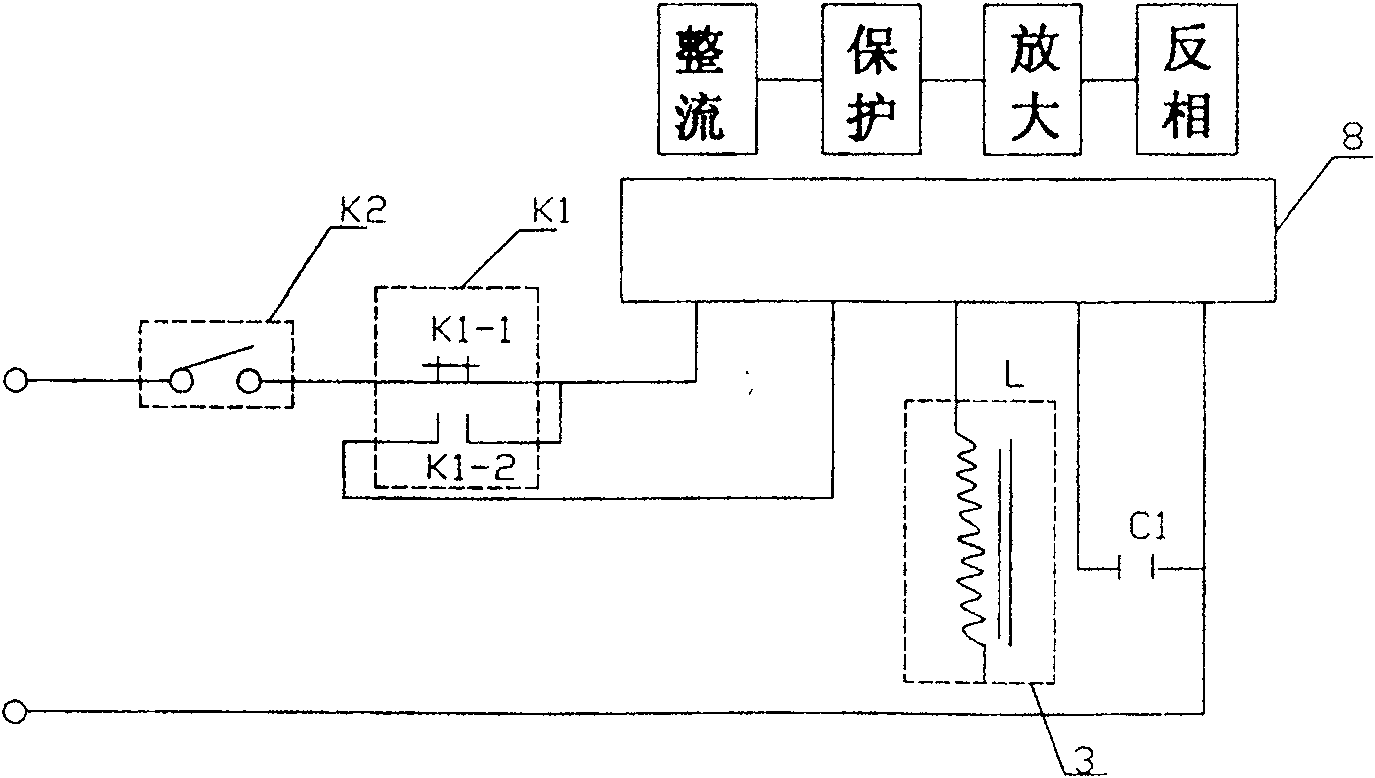

[0030] figure 2 It is a structural schematic diagram of the device of the present invention. The contactor of the present invention includes: a main body 1, an upper moving iron core 2, a lower static iron core 5 opposite to the upper moving iron core 2, and an intermediate iron core wound on the lower static iron core 5. The coil 3, the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com