Porcelain enamel glaze for acid-resistant cast iron sanitary ware

A technology of sanitary ware and acid-resistant cast iron, which is applied in the field of enamel glaze, can solve the problems of easy cracking of enamel glaze layer, poor process performance, and poor chemical stability, and achieve the goal of improving acid-resistant chemical stability, opacification ability, and process performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

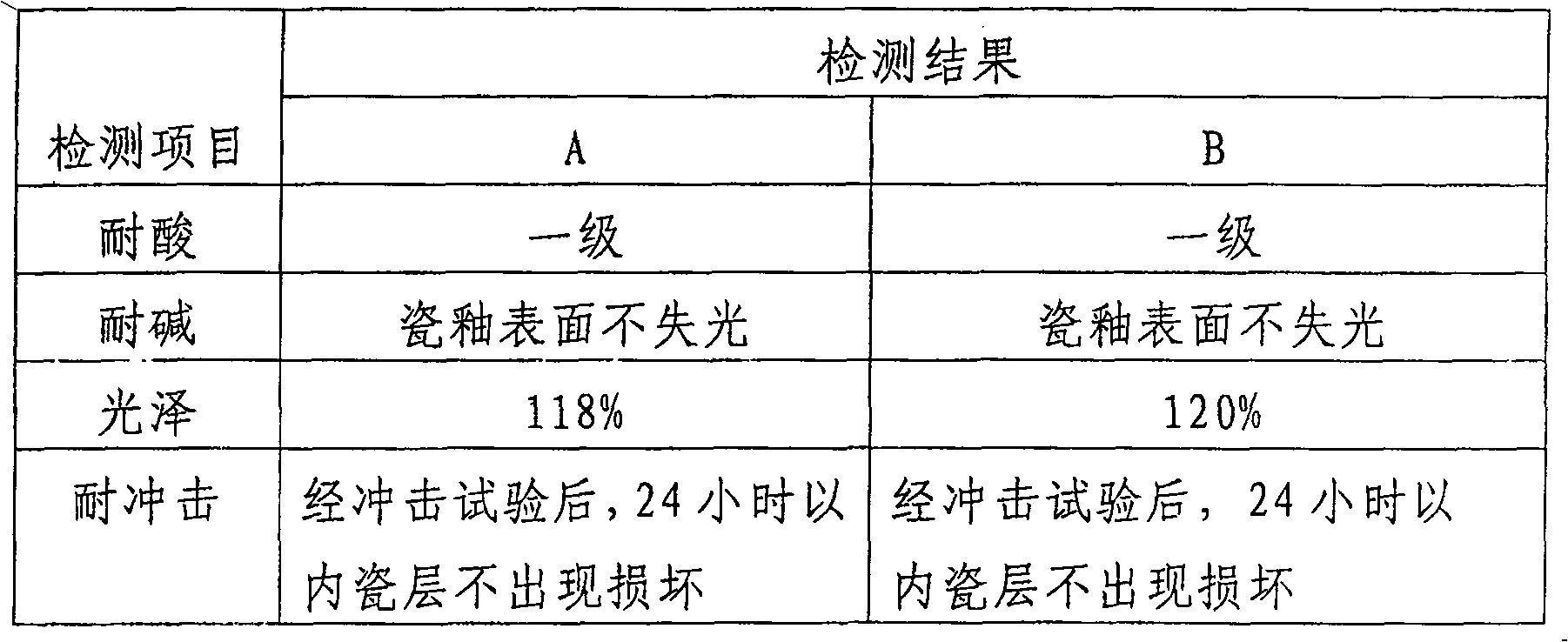

[0008] Select following two groups of formulas for use, and the components of each formula are parts by weight:

[0009] composition

Formula A

Formula B

SiO 2

52.5

43.5

al 2 o 3

0.4

3.0

B 2 o 3

6.5

6.2

K 2 o

1.0

1.0

Na 2 o

14.0

15.3

Li 2 o

1.2

1.5

CaF 2

2.5

4.4

Na 2 SiF 6

6.0

2.0

Sb 2 o 3

5.6

7.5

ZrO 2

1.0

1.5

TiO 2

8.5

6.0

CeO 2

0.5

0.6

La 2 o 3

0.3

0.5

PbO

0

7.0

[0010] Weigh the qualified chemical raw materials and mineral raw materials according to the formula, mix them thoroughly, put them into a crucible, and melt them at 1100-1200 ° C. After the raw materials are melted, stir them manually for 3-5 minutes. Then put the molten material into cold water and quench it into enamel f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com