Ultra large power two-dimensional semiconductor lock phase array stable oscillation mode technique

A super-power, semiconductor technology, used in semiconductor lasers, semiconductor laser devices, laser components, etc., can solve problems such as oscillation and intensified external cavity deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

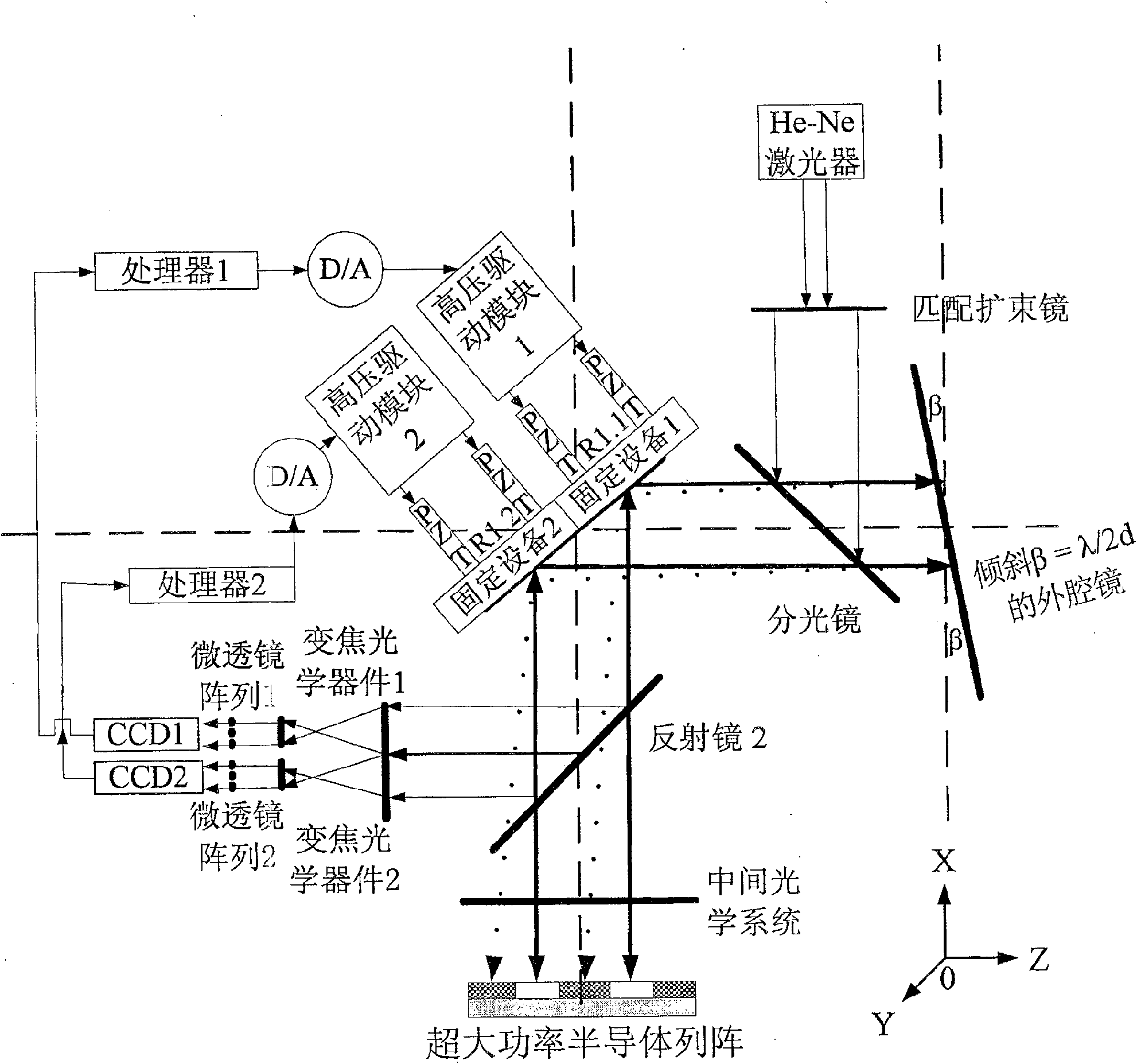

[0015] The He-Ne laser beam from the active sensing light source is expanded by the matching beam expander, reflected by the beam splitter, and projected to the 1 / 4Talbot external cavity mirror. After being reflected, it passes through the beam splitter and passes through the mirror R1.1 After being reflected by R1.2 and reflector 2, the He-Ne laser beam corresponding to R1.1 is imaged on CCD1 by zoom optical device 1 and microlens array 1, and the He-Ne laser beam corresponding to R1.2 is imaged by zoom optical device 2 , Microlens array 2 is imaged on CCD2, corresponding to the spot centroid of any sub-aperture (x C ,y C ),accessible

[0016] x C = Σ i , j M , N x ij ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com