An obtainment technology for external cavity distortion compensation and half compensation of ultra-high power semiconductor array

An ultra-high-power, semiconductor technology, applied in the field of phase-locked ultra-high-power semiconductor arrays, which can solve problems such as vibration and increased deformation of the external cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

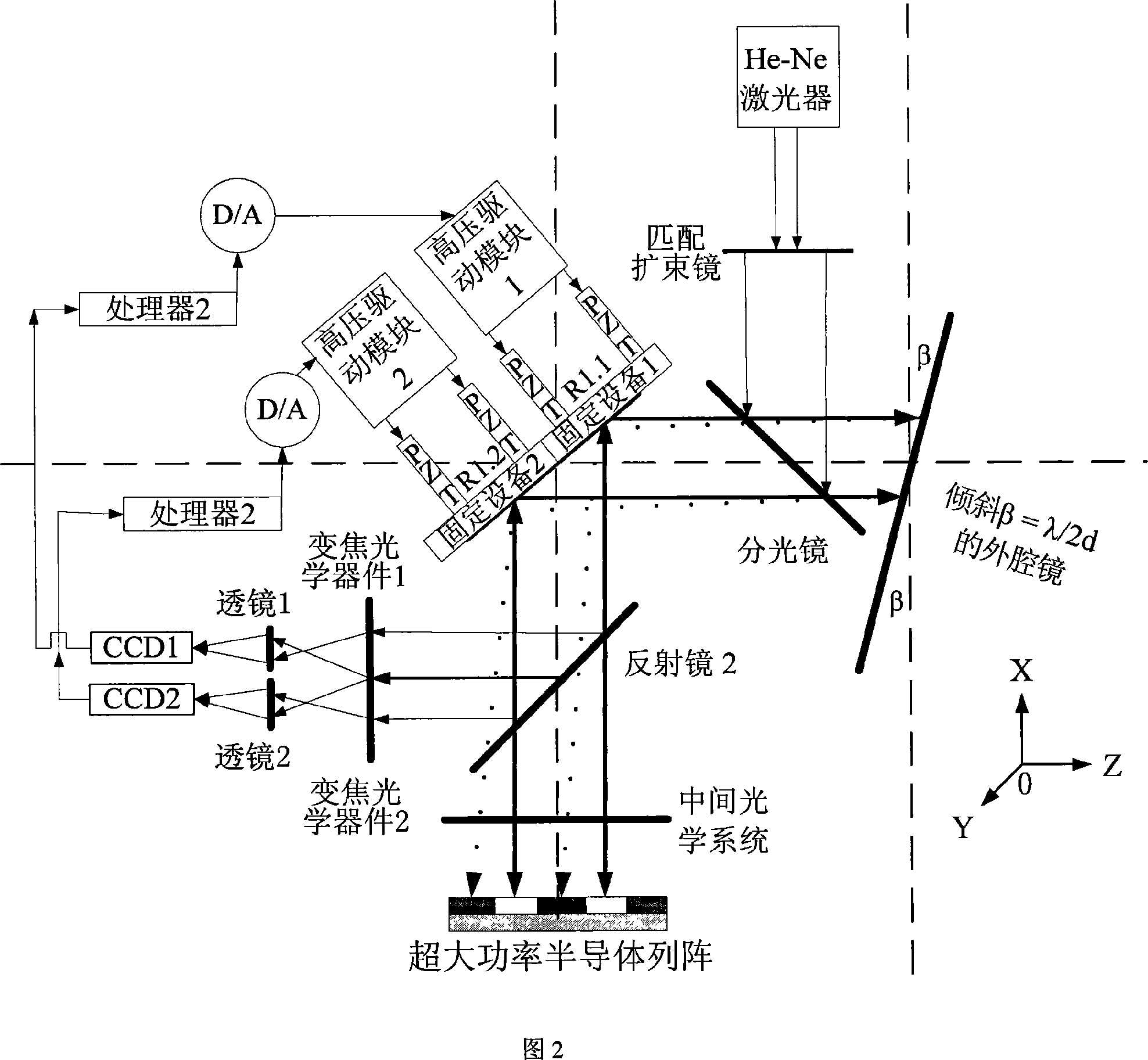

[0014] The He-Ne laser emitted by the sensing and detection light source is expanded by the matching beam expander, reflected by the beam splitter, and projected onto the reflective surface of the 1 / 4Talbot external cavity mirror with an inclination of β, and then the laser beam reflected by the external cavity mirror It will pass through the beam splitter and shoot to the mirrors R1.1 and R1.2. After being reflected by the mirror 2, the zoom optical device 1 adjusts the laser beam from R2.1, so that the lens 1 focuses its own incident beam on the CCD1, and At the same time, zoom optics 2 adjusts the laser beam from R2.2 so that lens 2 images the other half of the incident beam on CCD2.

[0015] The spot centroid on the CCD is (x C ,y C ),pass

[0016] x C = Σ i = 1 M Σ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com