Micro mist control system

A control system and micro-mist technology, which is applied in the direction of capturing or killing insects, liquid spraying devices, spraying devices, etc., can solve the problem of inaccurate ratio of liquid medicine, poor spraying effect, affecting the efficacy of liquid medicine, etc. problems, achieve good spraying effect, save liquid medicine, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

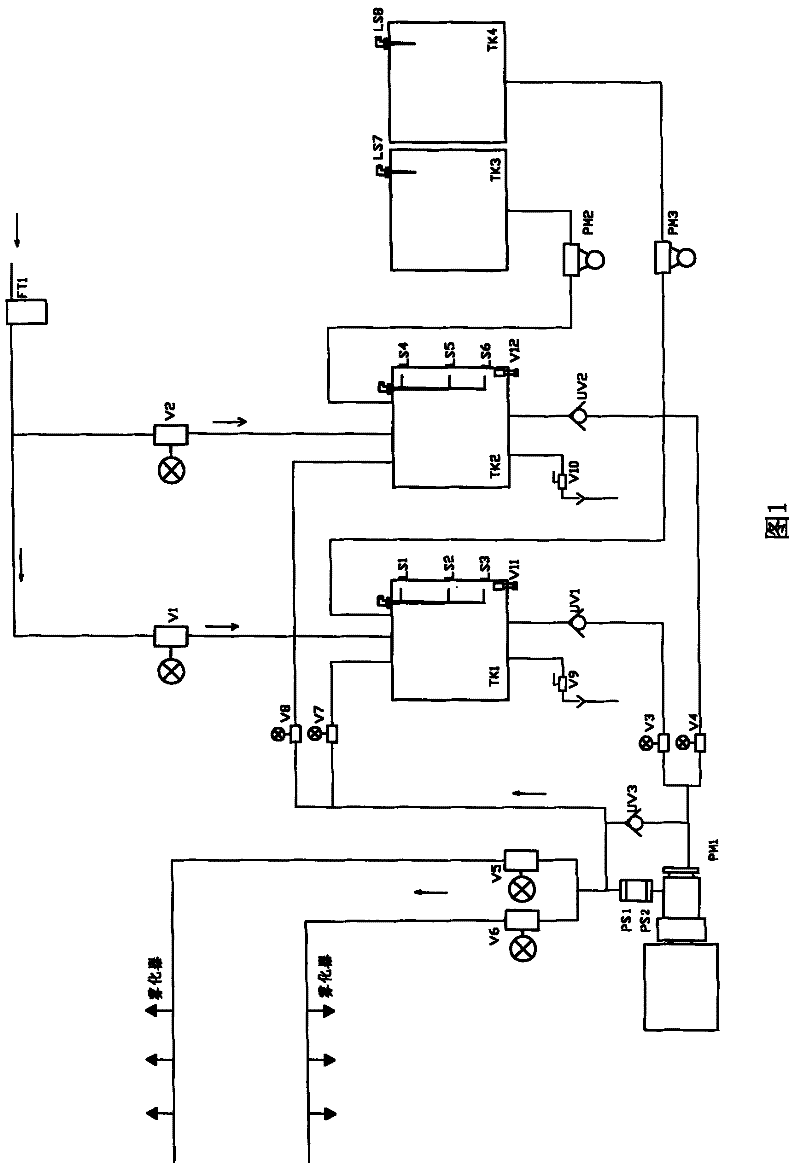

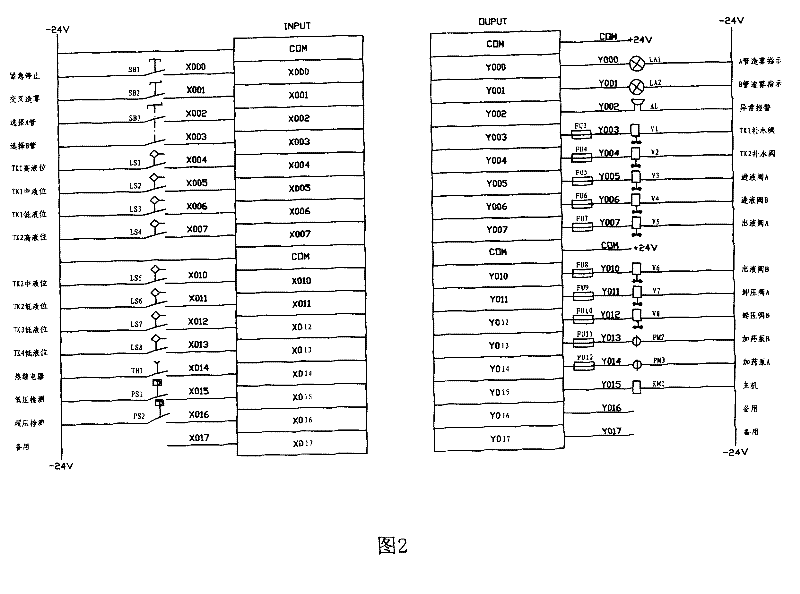

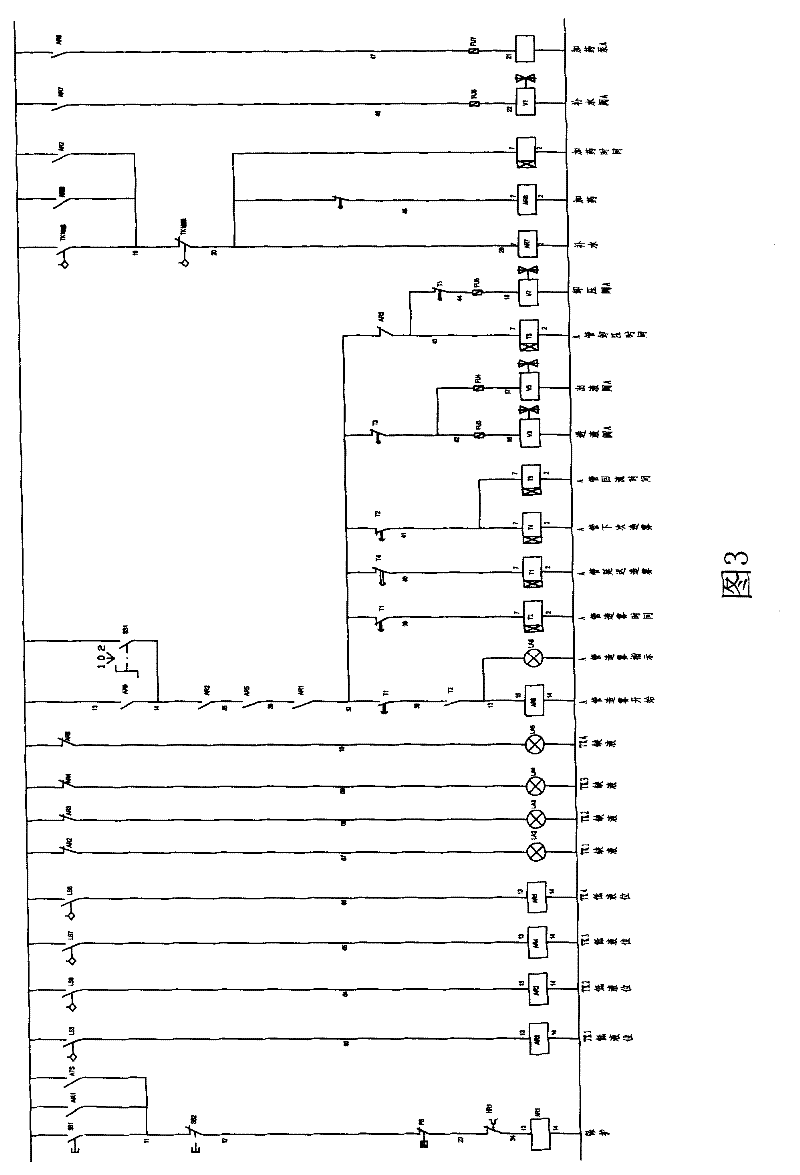

[0019] Such as figure 1 As shown in , it is the control principle diagram of Embodiment 1 of the present invention, mainly including two blending tanks TK1, TK2, two stock solution tanks TK3, TK4 and a high-pressure pump PM1, forming two pipes with the same structure A and B Take the A road as an example, the liquid outlet of the raw liquid tank TK4 is connected to a liquid inlet of the blending tank TK1 after passing through a dosing pump PM3, and the output of the tap water pipeline passes through the tap water filter FT1 and the replenishment valve V1 is then connected to the second liquid inlet of the blending tank TK1, and the liquid outlet of the blending tank TK1 is connected to the liquid inlet of the high-pressure pump PM1 after sequentially passing through the one-way valve UV1 and the liquid inlet valve V3, The liquid outlet of the high-pressure pump PM1 is connected to the atomizer after passing through the liquid outlet valve V5, and a two-stage pressure sensor is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com