Hydraulic four-side rotating pegboard machine

A splicing machine, hydraulic technology, applied in the direction of veneer press, plywood press, wooden veneer joining, etc., can solve the problem of lack of safe operation device, uncontrollable pressure fluctuation, difficult to clean piecing glue, etc. To achieve the effect of reducing the labor intensity of workers, reducing downtime and cleaning time, and running safely, smoothly and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

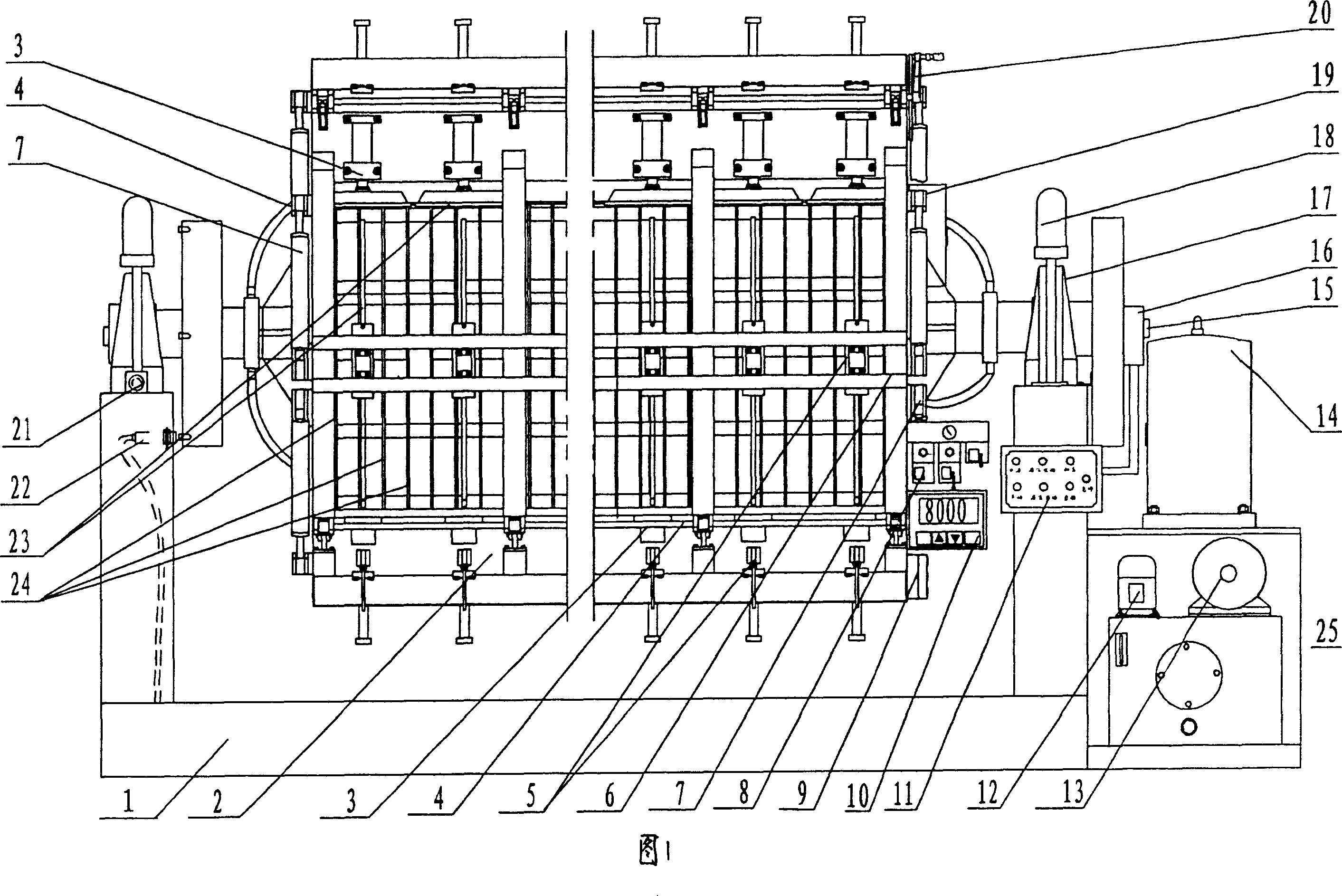

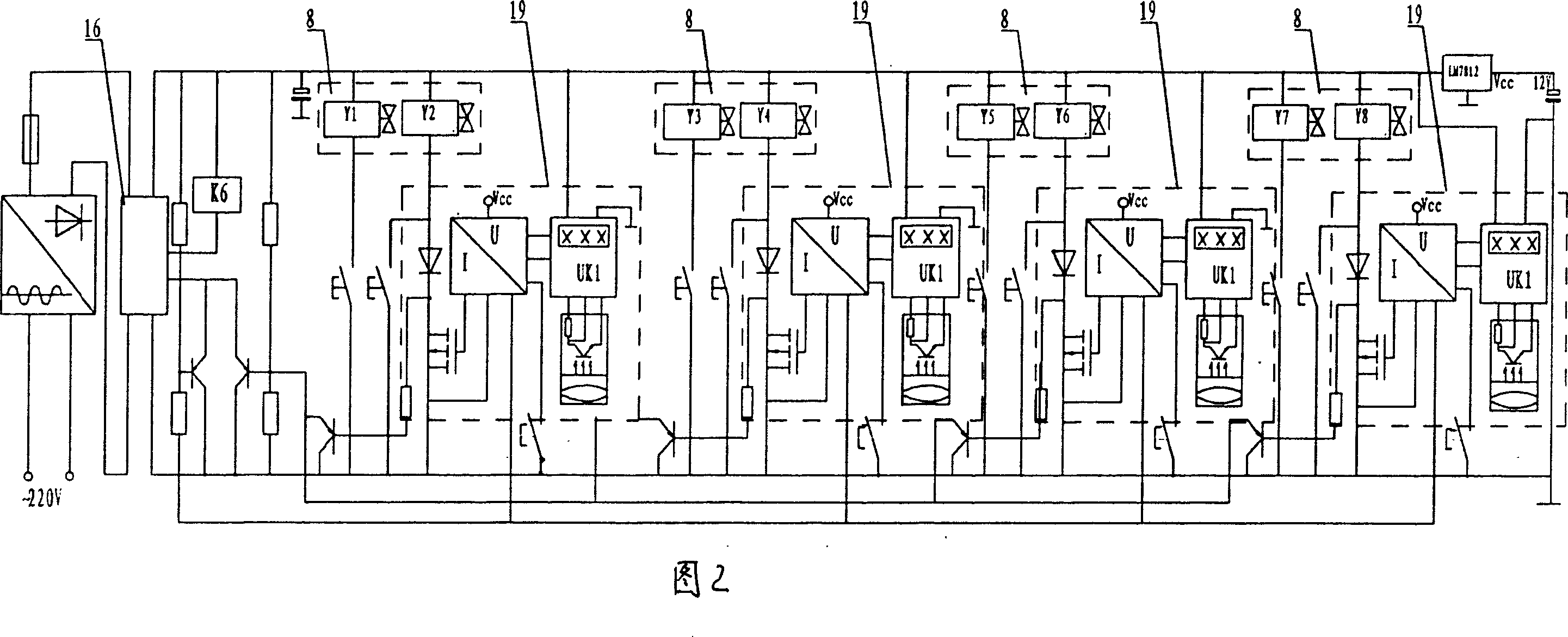

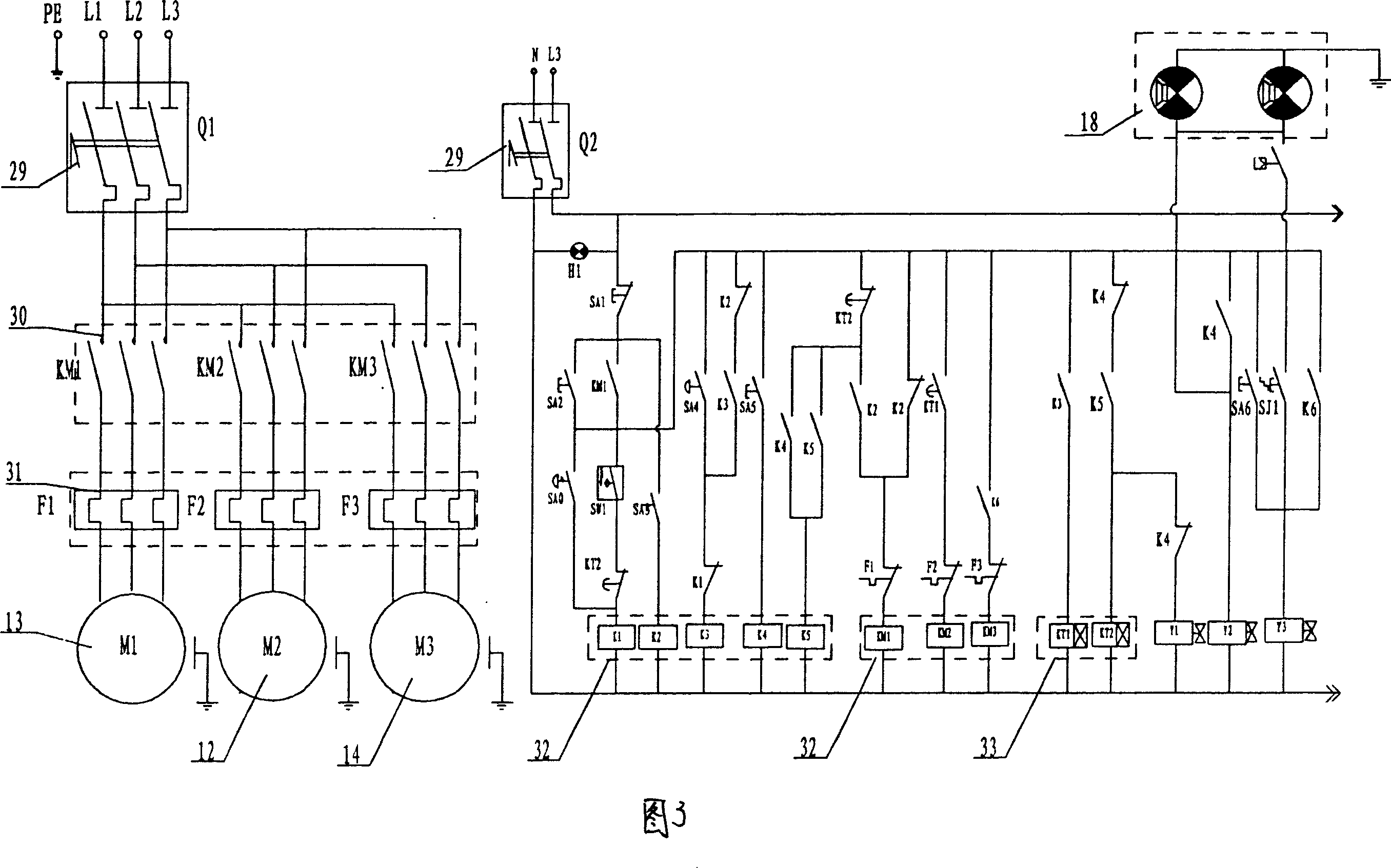

[0012] Embodiment 1, referring to Figs. 1, 2, and 3, is processed into a frame 1, and four identical surfaces are formed into 90 with each other. Assembled into a four-sided rotating workbench 2, each surface is equipped with a positive pressure cylinder 3, and a side pressure cylinder 5 is installed on the side. Each positive pressure cylinder 3 is connected by an oil pipe 4, and each side pressure cylinder 5 is connected by an oil pipe 6, each side A compression frame door is installed on the compression frame door, and a rotating shaft is installed on the compression frame door. The side lift valve cylinder, oil pipe 7 and locking mechanism 20 are installed on the rotating shaft. Both ends of the four-sided rotating workbench 2 are supported on the frame by the half shafts 17 equipped with bearings. On 1, the side axle of the bearing 17 is equipped with a sprocket to cooperate with the turbine reducer 14; the button station 11 is fixed on the frame 1; the electrical box 25 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com