Preparation process and application of perfumery nano capsule dispersant liquid

A nanocapsule and dispersion technology, which is applied in microcapsule preparation, microsphere preparation, essential oil/spice, etc., can solve the problems of easy friction and slip, easy washing, easy blocking of mesh holes, etc., and achieves the effect of good processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of lavender spice nanocapsule dispersion:

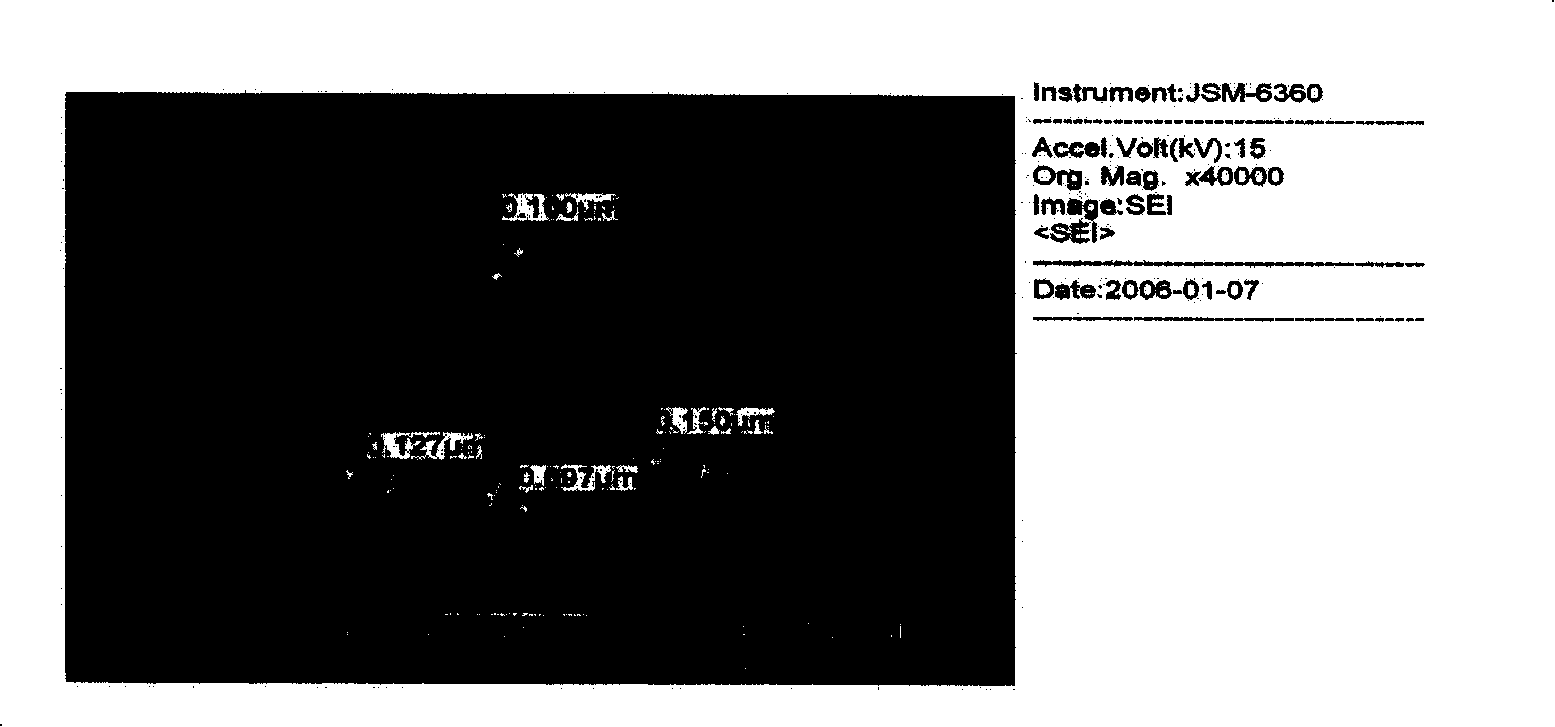

[0032] Homogenize 50 parts of lavender essence, 15 parts of dispersing emulsifier, and 300 parts of distilled water in a high-shear mixing emulsifier at a high speed at a speed of 10,000 rpm. After 30 minutes, adjust the pH to 2.5 to 3.5 with acetic acid, and then homogenize The emulsion was poured into a three-necked flask and placed in a constant temperature water bath. Under stirring conditions and a stirring speed of 300rpm, 80 parts of etherified melamine resin prepolymer was added dropwise, and the temperature was raised to 60°C. Wall; after cooling the system to room temperature, add 80 parts of etherified melamine resin prepolymer dropwise under stirring condition, raise the temperature to 70°C, keep it warm, and carry out the second wall building. Cool and neutralize to pH=7 to obtain a lavender nanocapsule dispersion. Gained fragrance nanocapsule electron micrograph is shown in figure 1 .

Embodiment 2

[0034] Scent finishing of colored cotton knitted fabrics:

[0035] Process: padding method: padding (two dipping and two rolling, liquid carrying capacity 70%) → drying (90-100°C)

[0036] Padding solution prescription:

[0037] Lavender essence nanocapsule dispersion 50g / L

[0038] Formaldehyde-free super soft adhesive 30g / L

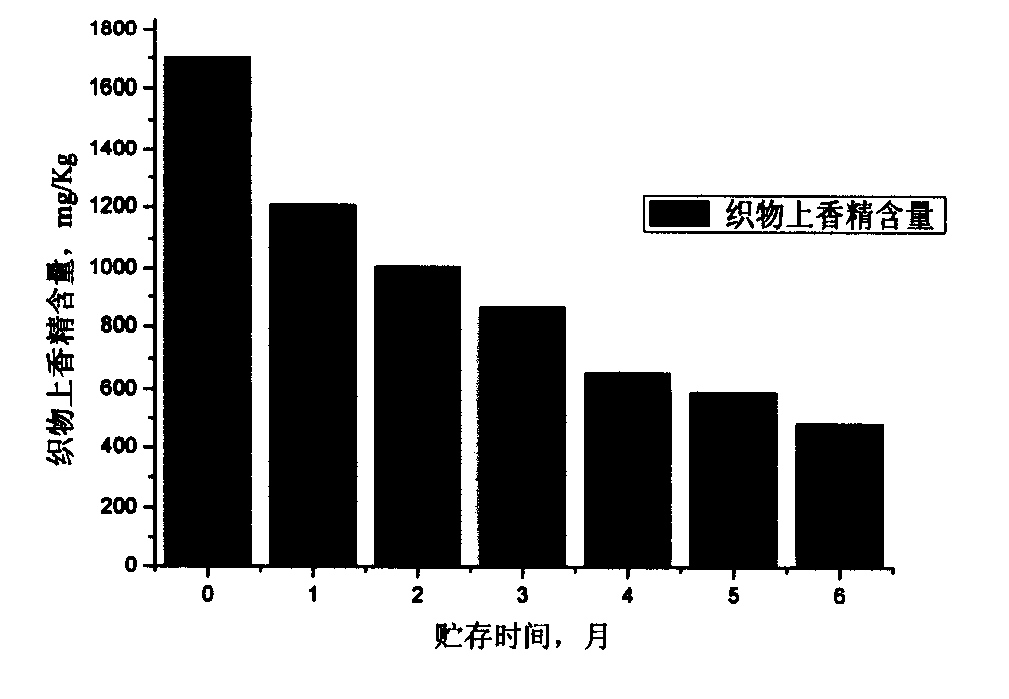

[0039] The color of the colored cotton fabric before and after fragrance finishing is basically the same, and the hand feeling has little change. The formaldehyde content is 5.3mg / kg. After the colored cotton knitted fabric is washed 20 times, the fragrance content in the fabric only decreases by about 29%. The fabrics treated with fragrance nanocapsules were stored openly, and as the storage time prolongs, the fragrance content on the fabrics decreases continuously, see figure 2 Shown, to 6 months, still have the essence of 450mg / Kg to remain in the capsule of fabric, and fabric sends out pleasant fragrance.

Embodiment 3

[0041] Preparation of Baiaishen essence nanocapsule dispersion:

[0042] Homogenize 30 parts of Baiaishen essence, 10 parts of anionic dispersant, 5 parts of nonionic emulsifier, and 300 parts of distilled water in a high-shear mixing emulsifier at a high speed. The homogenization rate is 10,000 rpm. After 30 minutes, adjust with acetic acid The pH is 3-4, then pour the homogenized emulsion into a three-necked flask, put it into a constant temperature water bath, and under stirring conditions, at a stirring speed of 300rpm, add 80 parts of etherified melamine resin prepolymer dropwise, and heat up To 56°C, keep it warm for 2 hours to build a single-layer wall; after cooling the system to room temperature, add 80 parts of etherified melamine resin prepolymer dropwise under stirring conditions, raise the temperature to 70°C, keep it warm, and carry out the second wall build . Cool and neutralize to pH=7 to obtain Baiaishen essence nanocapsule dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com