Heat-storage and heat-preservation microcapsules and preparation method and application thereof

A microcapsule and heat storage technology, applied in the directions of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problem that the overall performance of textiles changes greatly, the wear resistance and durability of microcapsule shells are difficult to break through, and Change material leakage and other problems, to achieve the effect of good wear resistance and durability, maintaining temperature control function, and large phase change energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

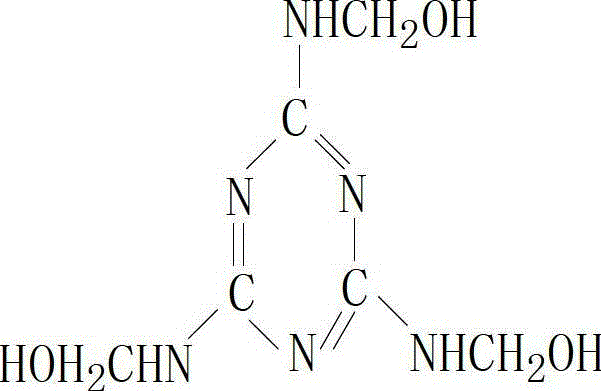

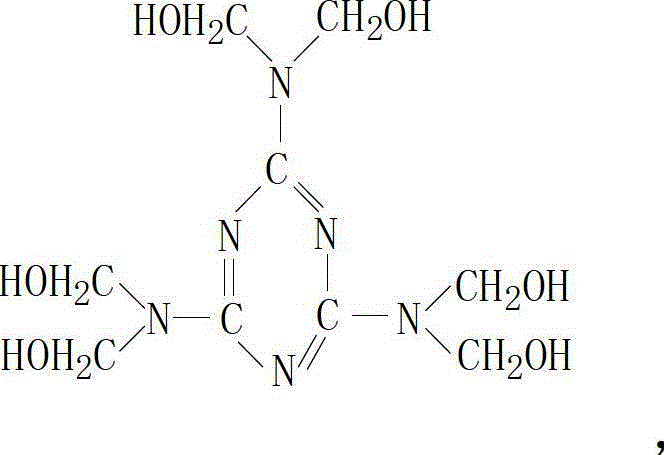

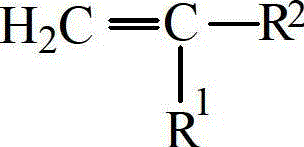

Method used

Image

Examples

Embodiment 1

[0035] At 40℃, 50 parts of No. 30 paraffin, 802 parts of Span, 803 parts of Tween, and 200 parts of distilled water are homogenized in a high-speed shearing mixer emulsifier at high speed at a homogenization rate of 10000rpm. After 30 minutes, homogenize The emulsion was poured into a three-necked flask, placed in a constant temperature water bath, heated to 80°C under stirring, added 0.5 parts of ammonium persulfate and 20 parts of methyl acrylate to build the inner wall. After cooling, adjust the pH to 2~4 with acetic acid, add 80 parts of etherified melamine resin dropwise at a stirring speed of 300rpm, heat up to 55℃, keep for 1~2h to cool the outer layer, and neutralize the ammonia to pH =7, the heat storage and heat preservation microcapsule solution is obtained, and the powdered heat storage and heat preservation microcapsule No. 1 is obtained by spray drying.

Embodiment 2

[0037] Pure knitted fabric for heat storage and heat preservation finishing:

[0038] Process: Adopt padding method: padding (two dips and two rolls, 70% liquid carrying capacity) → drying (90~100℃) 2min

[0039] Padding liquid prescription:

[0040] Thermal storage and thermal insulation microcapsule No. 1 50g / L

[0041] Formaldehyde-free super soft adhesive 30g / L

[0042] The color of the pure cotton before and after finishing is basically the same, and the hand feel is almost unchanged. The formaldehyde content is 6.7mg / kg. After the knitted fabric has been washed 20 times, the Crow value is only reduced by 0.3 after the thermal insulation tester.

Embodiment 3

[0044] At 55℃, 10 parts of No. 52 paraffin, 40 parts of No. 30 paraffin, 6 parts of sodium lauryl sulfate, 804 parts of Tween, and 300 parts of distilled water are homogenized in a high-speed shearing mixer emulsifier at high speed, and the homogenization rate is 10000rpm After 30 minutes, pour the homogenized emulsion into a three-necked flask and put it in a constant temperature water bath. Under stirring, the temperature is raised to 80°C and 0.5 parts of potassium persulfate and 22 parts of ethyl methacrylate are added to make the inner layer. After cooling the wall, adjust the pH to 3~4 with citric acid, add 80 parts of etherified melamine resin dropwise at a stirring speed of 300rpm, heat up to 55℃, keep for 1~2h to make the outer layer single-layer wall; After the system is cooled to room temperature, 80 parts of etherified melamine resin are added dropwise again under stirring conditions, the temperature is raised to 65° C., the temperature is kept, and the second wall b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com