Gas insulation switch device

A gas-insulated switch and insulating sleeve technology, which is applied in switchgear, switchgear setting, panel/switch station circuit device, etc., can solve the problems of increased manufacturing cost, unsightly appearance, increased connection surface, etc., and achieves zero reduction. The number of parts, convenient inspection and maintenance, high stability and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

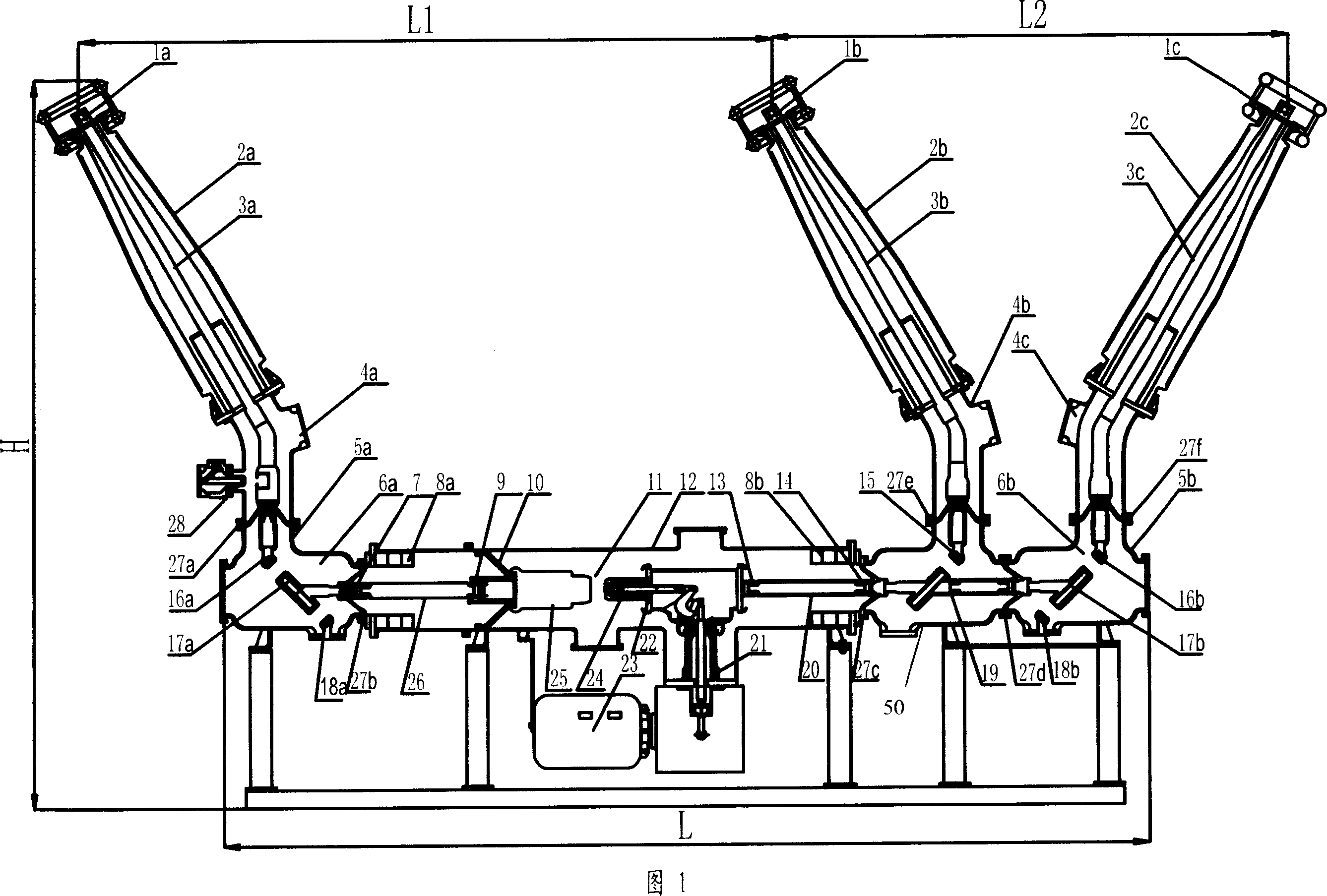

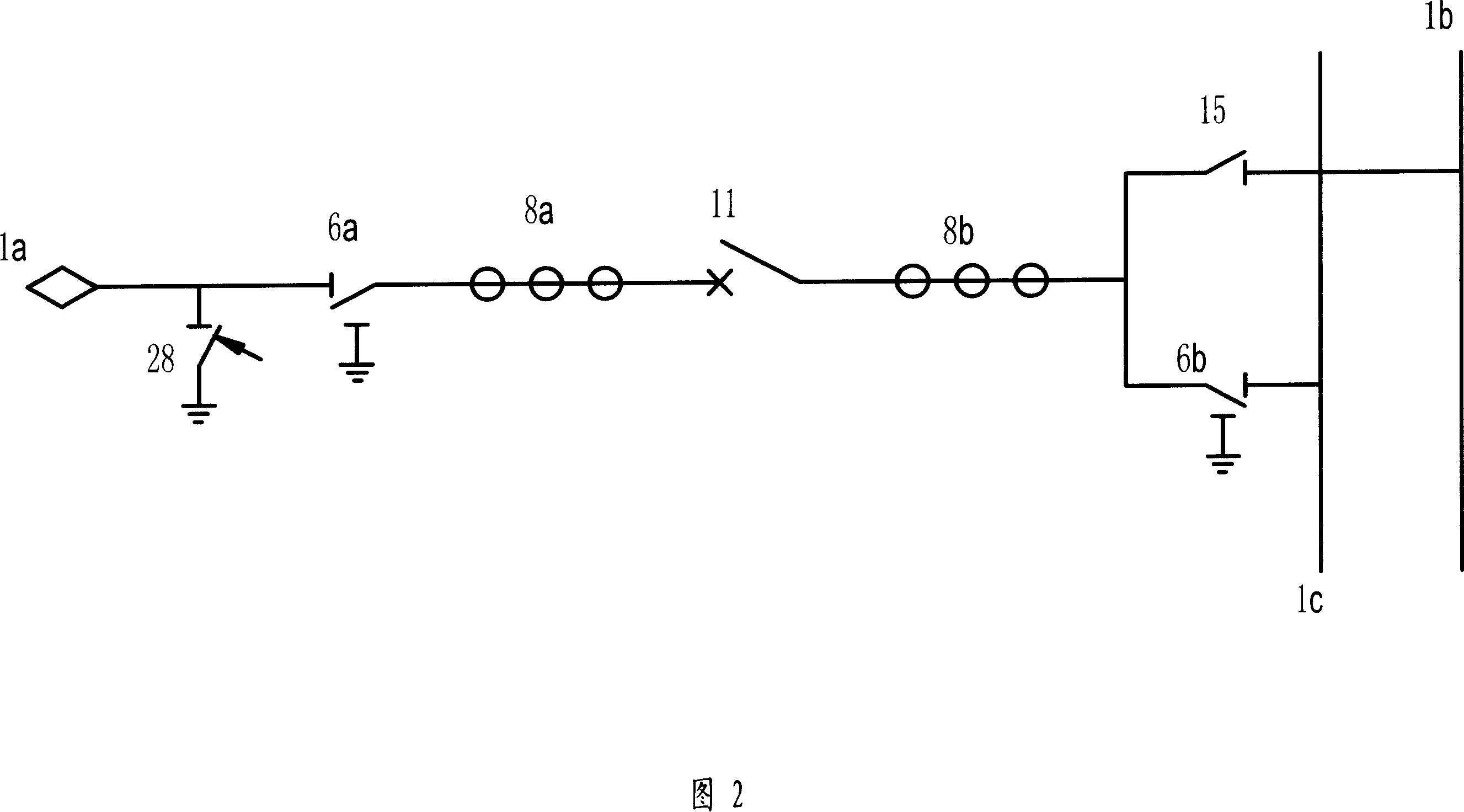

[0032] FIG. 1 shows a cross-sectional structure of a gas insulated switchgear (HGIS) according to a first embodiment of the present invention. Figure 2 is a schematic circuit diagram of the HGIS. This embodiment is applied to a double-bus power station in a power system.

[0033] In this embodiment, the circuit breaker 11 and the current transformers 8a, 8b are arranged horizontally in an axially extended housing 12, and the isolation grounding switch 6a and the isolation grounding switch 6b connected to the isolation switch 15 are placed on the left and right sides of the circuit breaker 11 respectively. The isolated ground switch containers 5a and 5b.

[0034] The housing 12 is made of aluminum material into a horizontal cylinder with a horizontal axis. Insulating pots 27b, 27c are installed at the two ends of the housing; they are respectively connected to the left side of the isolating and grounding switch container 5a and the isolating switch container 50, and the right...

Embodiment 2

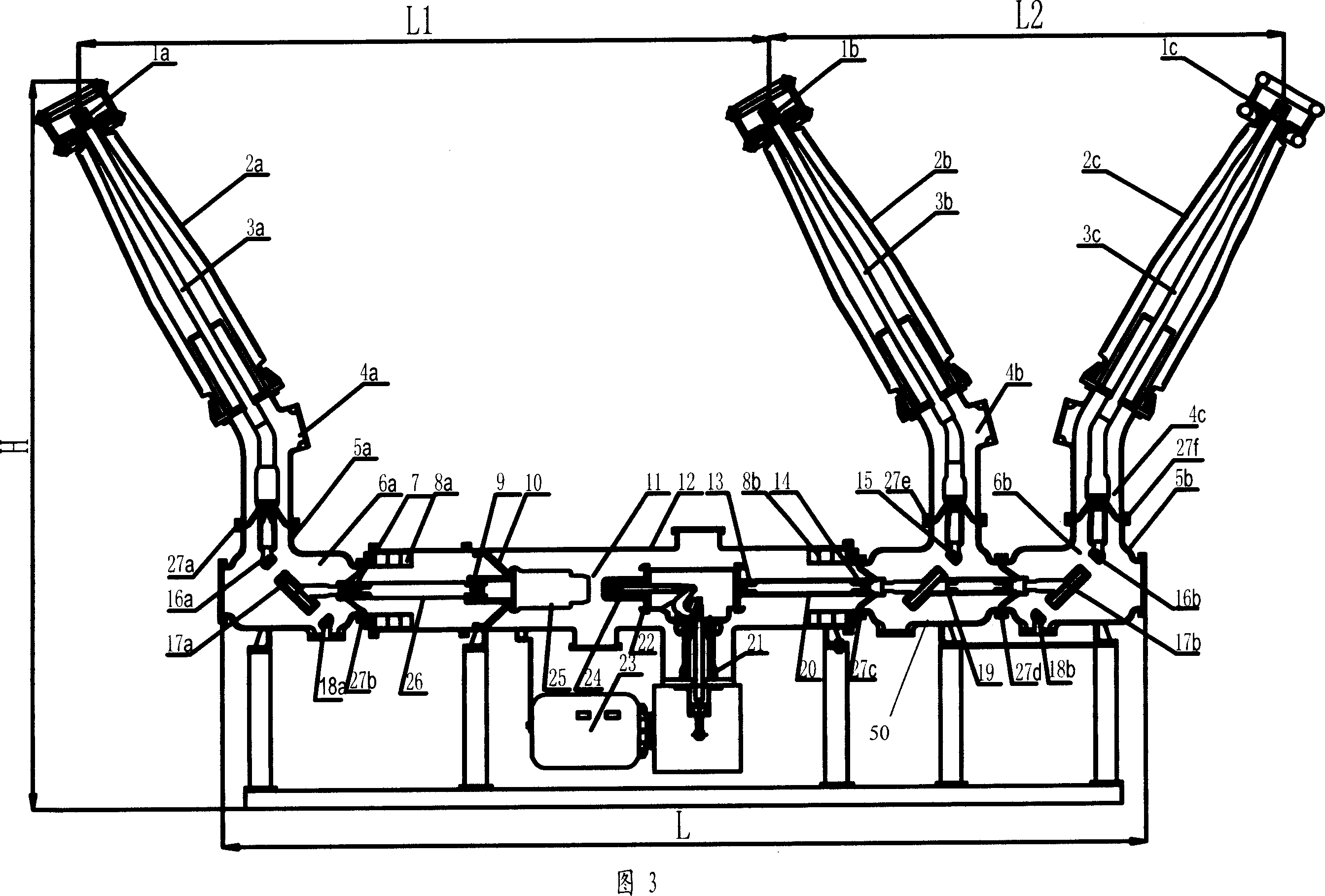

[0041] Fig. 3 is a cross-sectional view of an HGIS according to a second embodiment of the present invention.

[0042] According to the needs of the power system, sometimes the fast grounding switch 28 in FIG. 1 does not need to be installed on the incoming line side. In this embodiment, except that the fast grounding switch 28 is not provided, other configurations and structures are the same as those in Embodiment 1.

Embodiment 3

[0044] 4 and 5 are a sectional view and a circuit diagram of an HGIS according to a third embodiment of the present invention.

[0045] This embodiment is applied to a power station with single bus connection in the power system. The HGIS of this embodiment forms a conductive path through the power system overhead line 1a, the isolation grounding switch 6a, the current transformer 8a, the circuit breaker 11, the current transformer 8b, the isolation grounding switch 6b, and the bus bar 1b. Its structure is different from the first embodiment in that the isolating switch 15, the isolating switch container 50 and the metal airtight container 4b are omitted; the right side of the housing 12 is directly connected to the container 5b through the insulating basin 27c, and the connecting terminal 14 of the current transformer 8b is connected to the container 5b. The moving contact 17b of the isolating earthing switch 6b is directly connected, and the rest of the structure is the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com