Network system for managing textile equipment

A technology for managing networks and textile equipment, applied in the field of wireless network control systems, can solve the problems of high system difficulty, high hardware cost, and no function of downloading control data, and achieve the effect of simple hardware structure and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

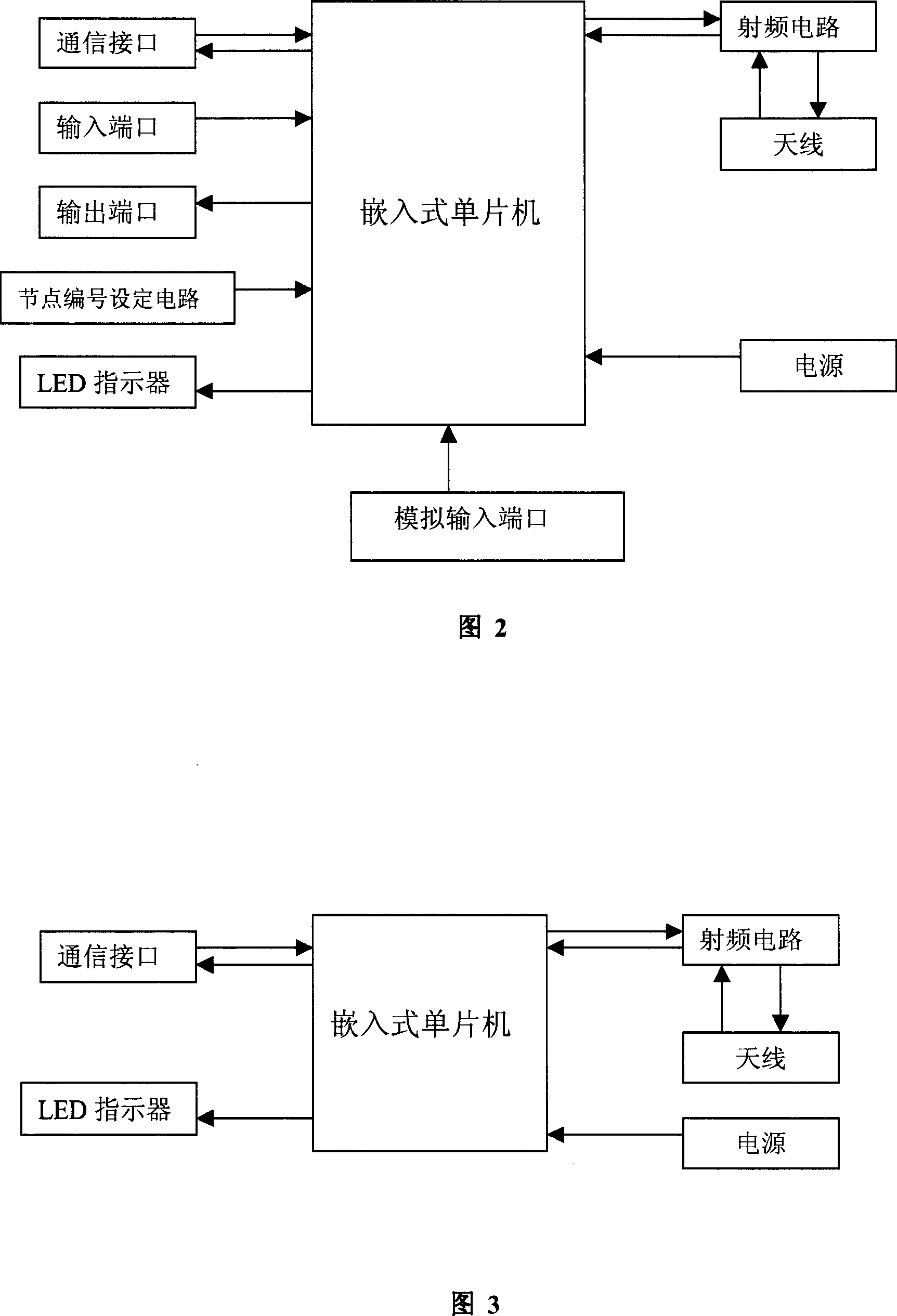

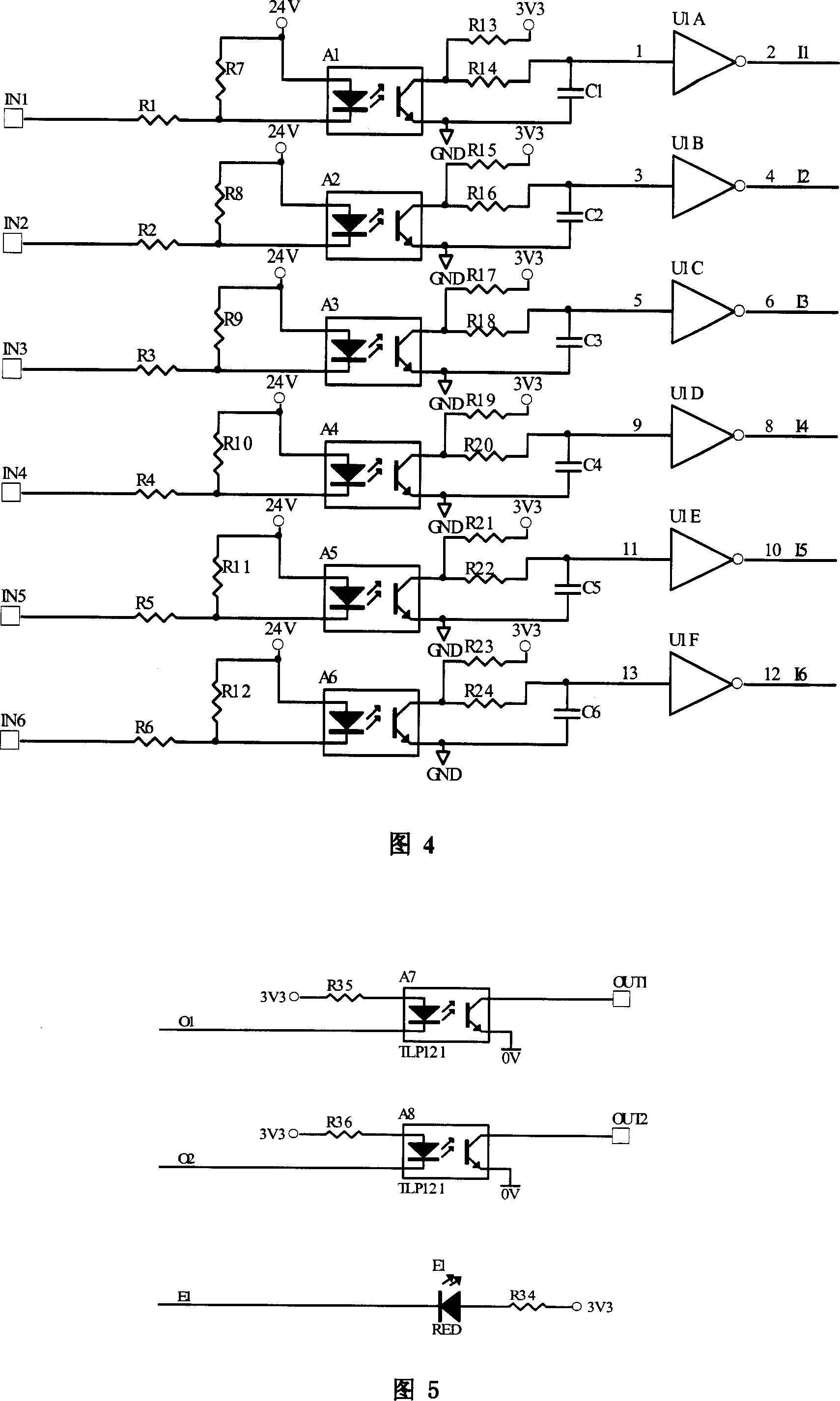

[0041]The complete implementation of the textile equipment management network system is divided into three aspects: one is the design of the textile factory network system, the other is the design and production of node units and management units, and the third is the on-site installation and implementation of the wireless network system in the actual environment of the textile factory. test. These three aspects are described in detail below:

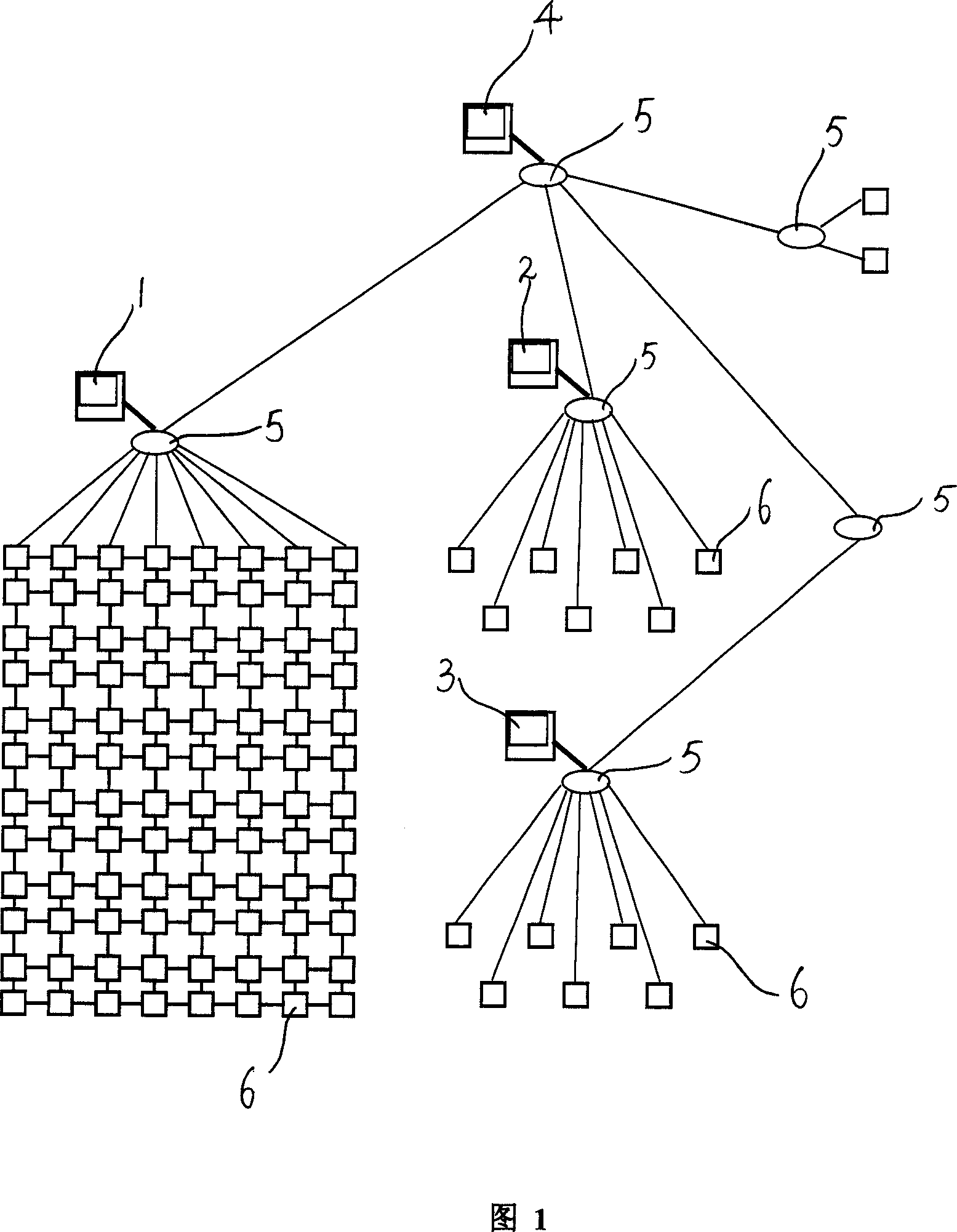

[0042] Fig. 1 is a schematic structural diagram of the textile equipment management network system of the present invention. The textile factory has a plurality of textile branch factories, such as a weaving branch factory and a spinning branch factory, and each textile branch factory is provided with a plurality of production workshops again, and the management computer is in Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com