Zymolysis method for producing lactic acid by bacillus subtilis to saccharify garbage from restaurant and cookroom

A technology of food waste and Bacillus subtilis, which is applied in the field of food waste fermentation to produce lactic acid, can solve the problem of high cost of lactic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

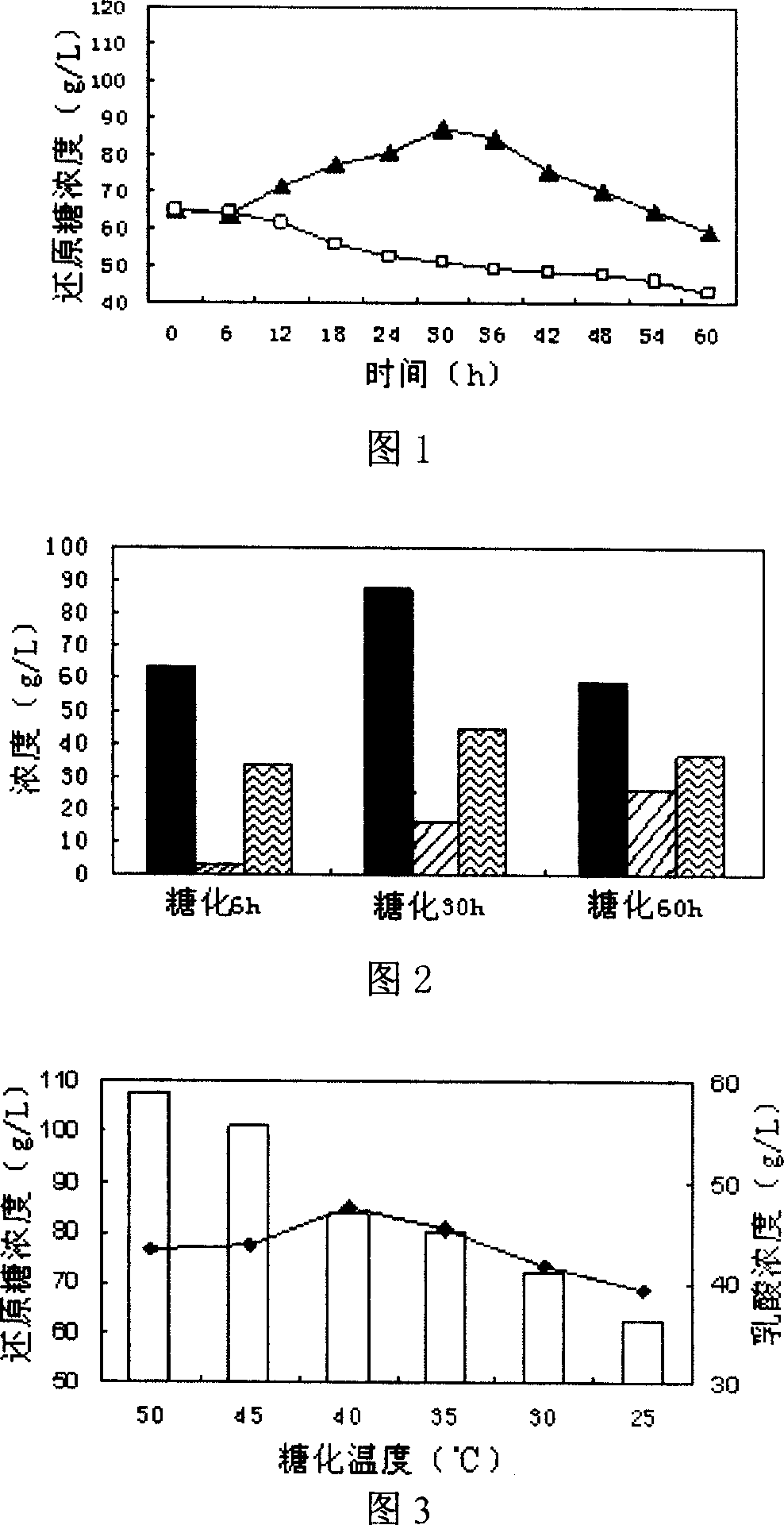

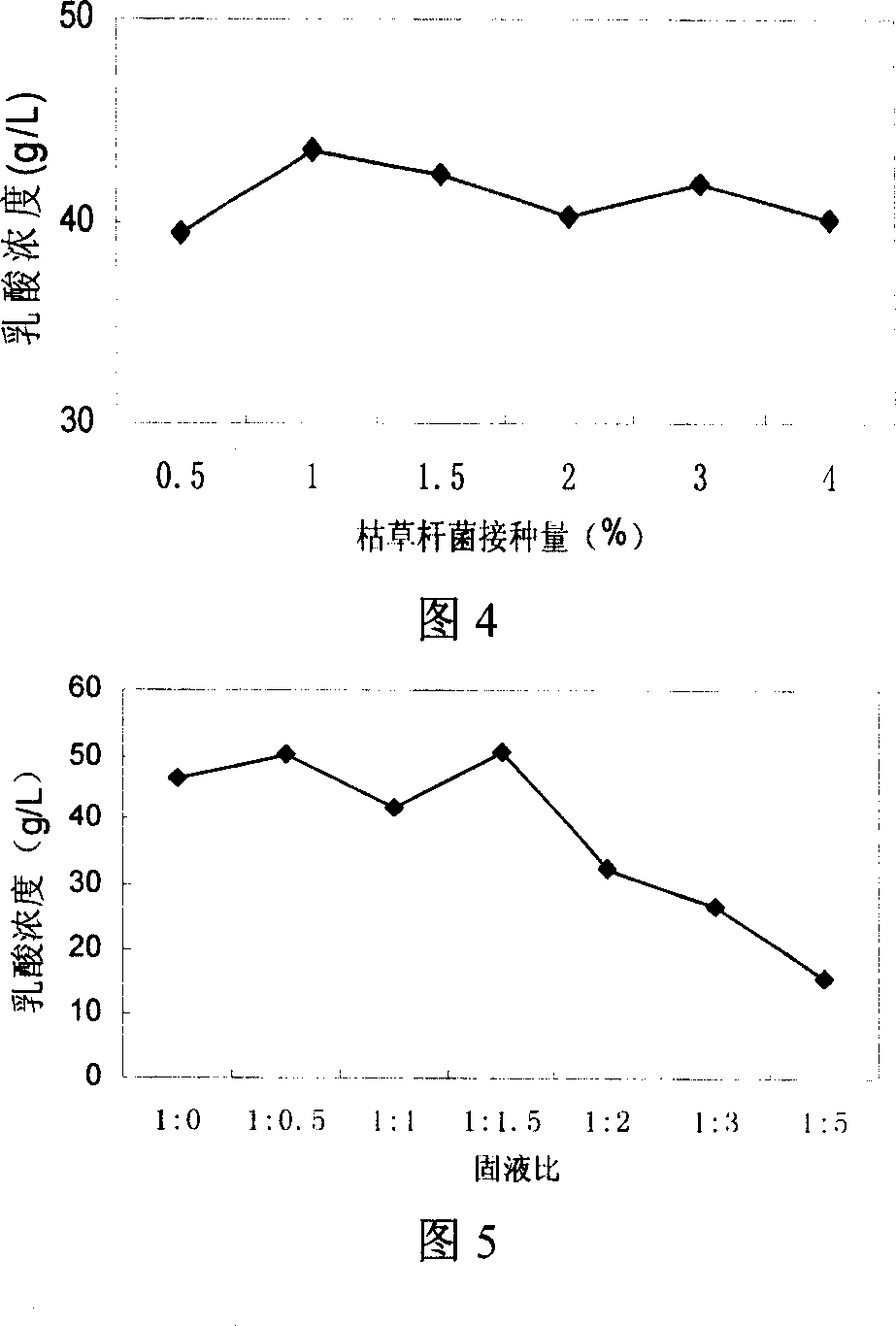

[0006] Specific Embodiment 1: In this embodiment, Bacillus subtilis saccharifies and ferments food waste to produce lactic acid through the following steps: (1) filtering and pulverizing the food waste; (2) adding subtilis accounting for 0.8% to 1.2% of the food waste mass (3) adding Bacillus subtilis to the food waste and saccharifying it for 25-35 hours at 35-45°C; (4) adding water 0.5-1.5 times the mass of solid food waste; (5) adding a solid-liquid mixed meal Lactic acid bacteria with 3% to 5% of the quality of kitchen waste, and adding calcium carbonate to maintain the pH value of the saccharified food waste at 6.2 to 6.4, and fermenting the saccharified food waste at 40 to 50°C for 26 to 30 hours; ( Six) solid-liquid separation, and then purifying the lactic acid in the filtered fermentation broth to obtain lactic acid.

[0007] Bacillus subtilis can directly saccharify and ferment food waste or other organic waste.

specific Embodiment approach 2

[0008] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: step (4) adding water with 0.7 to 1.3 times the mass of solid kitchen waste. Other steps are the same as those in Embodiment 1.

specific Embodiment approach 3

[0009] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the water that adds in the step (four) is tap water, kitchen waste filtrate or dining room, canteen waste water. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com