Stirring, blowing rotor in use for refining magnesium alloy

A magnesium alloy and rotor technology, which is applied in the field of magnesium alloy refining equipment, can solve the problems of reduced production efficiency, large consumption and high melting point, and achieves the effects of continuous and reliable work, avoiding energy waste and shortening refining time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

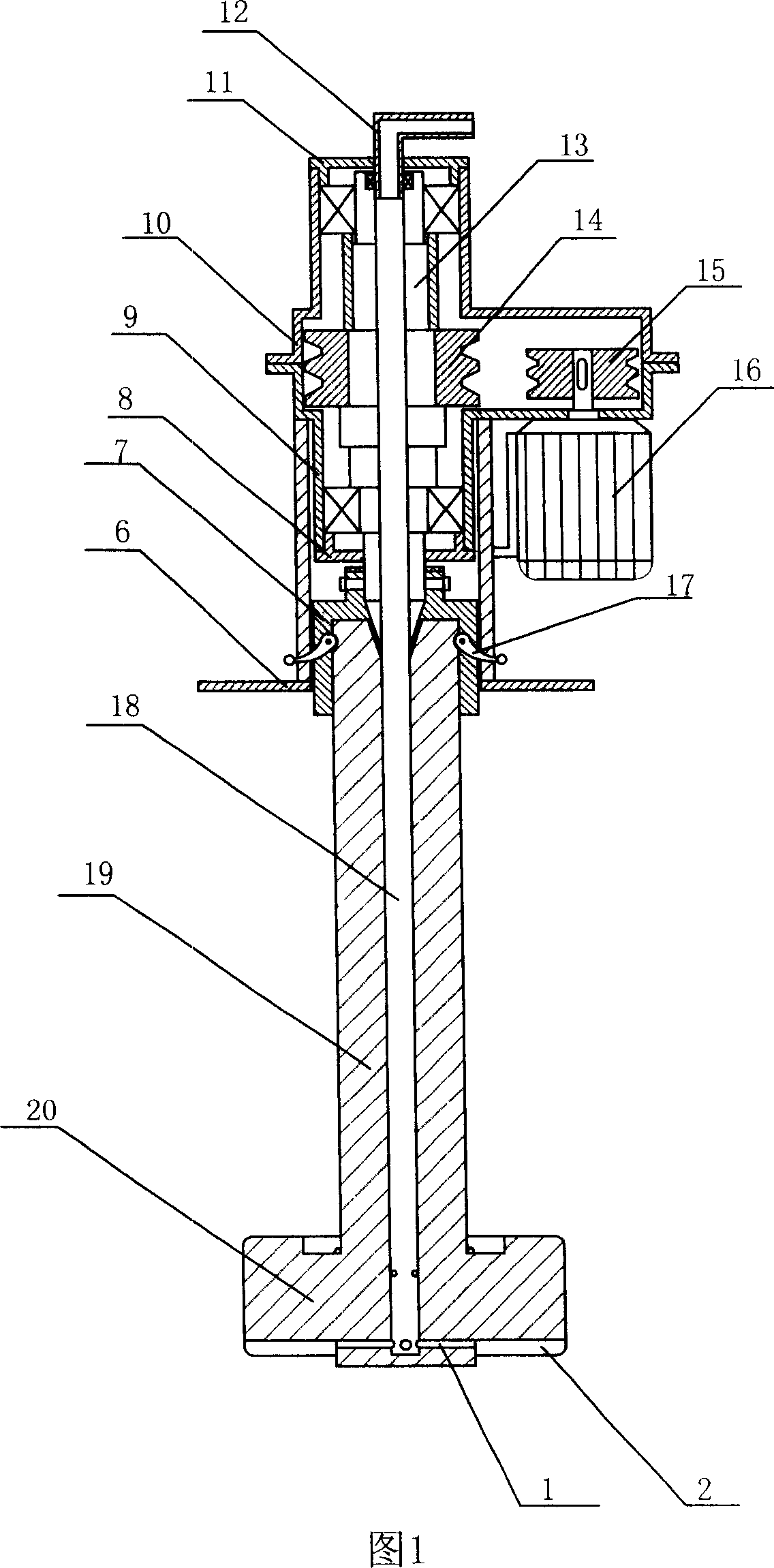

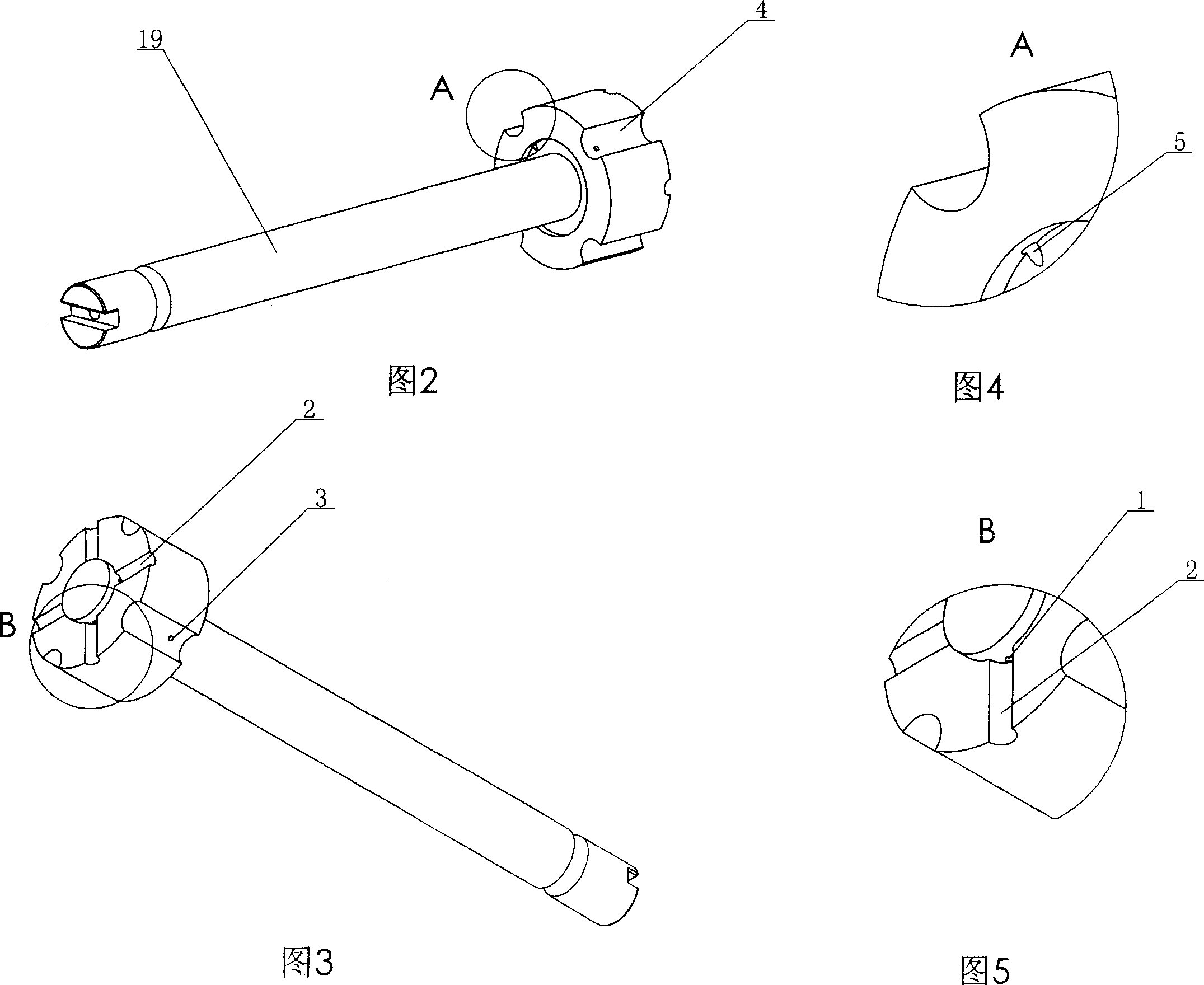

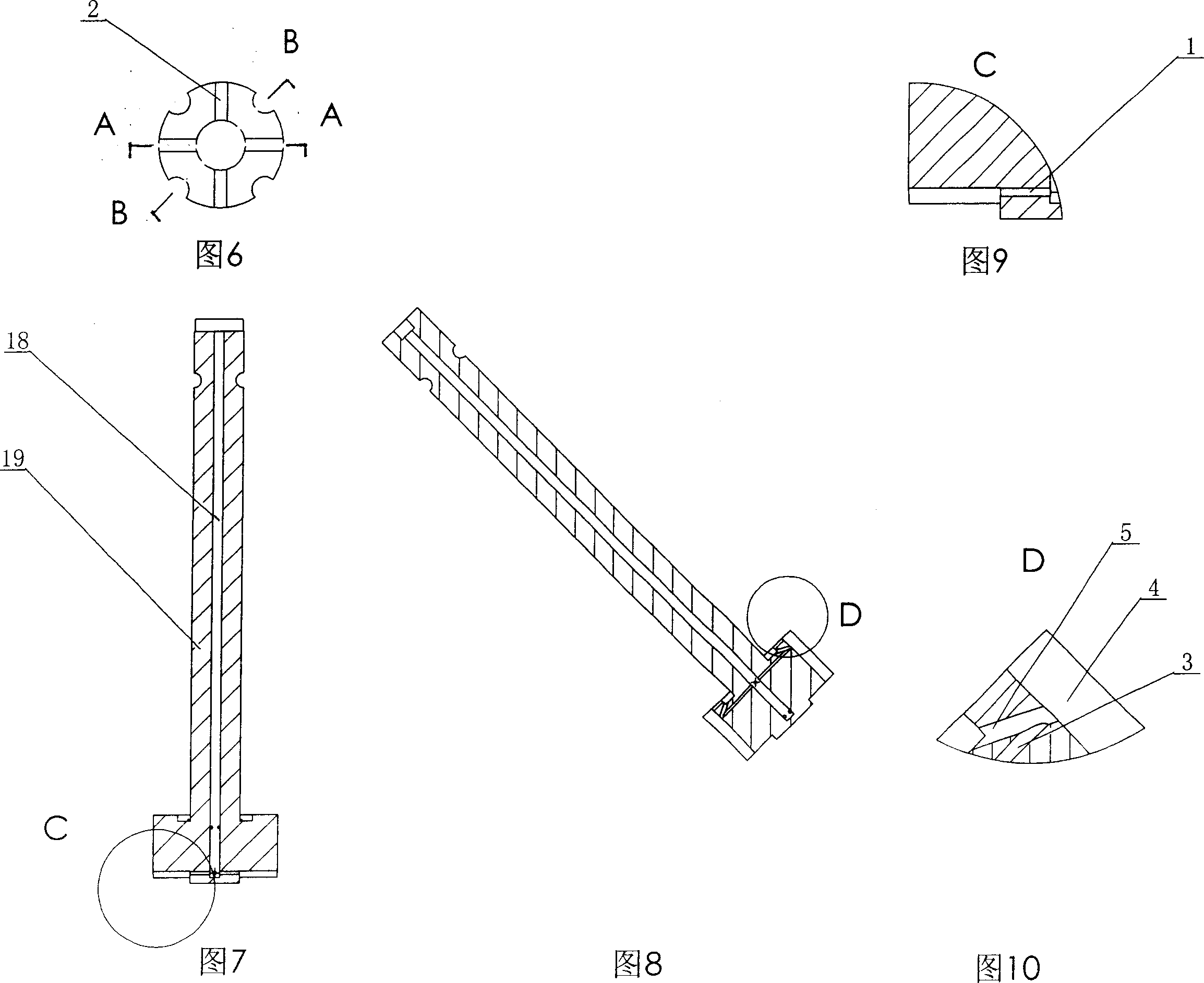

[0036] The embodiment of the present invention is shown in accompanying drawing 1, and the present invention comprises a rotor body 19 that has vent pipe 18, the through-hole shaft 13 that the upper and lower ends communicate with vent pipe 12 and rotor body 19 respectively, be arranged on the through-hole shaft 13 and The large transmission wheel 14 connected to the transmission device and the bearing seat arranged between the ventilation shaft 13 and the upper and lower housings 10, 9 are radially and uniformly arranged on the bottom end of the rotor body 19 and communicated with the ventilation pipe 18. Vent 1.

[0037] The fixing device of the rotor body 19 of the device of the present invention is composed of a supporting disc 6, a lower bearing end cover 8, an upper bearing end cover 11, a lower housing 9, and an upper housing 10, wherein between the supporting disc 6 and the lower housing 9 It is integrally welded and connected with the upper shell 10 by bolts. The low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com