Sound wave shock and pulse combustion type pressing crack apparatus

A pulsed combustion and acoustic wave technology, which is used in the production of fluids, wellbore/well components, and earthwork drilling, etc., can solve the problem that the fracturing effect of the fracturing project is difficult to meet the requirements, the combustion pressure peak rises quickly, and the pressure peak duration is short. and other problems, to achieve the effect of shortening the construction period, long pressure duration, and improving the recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

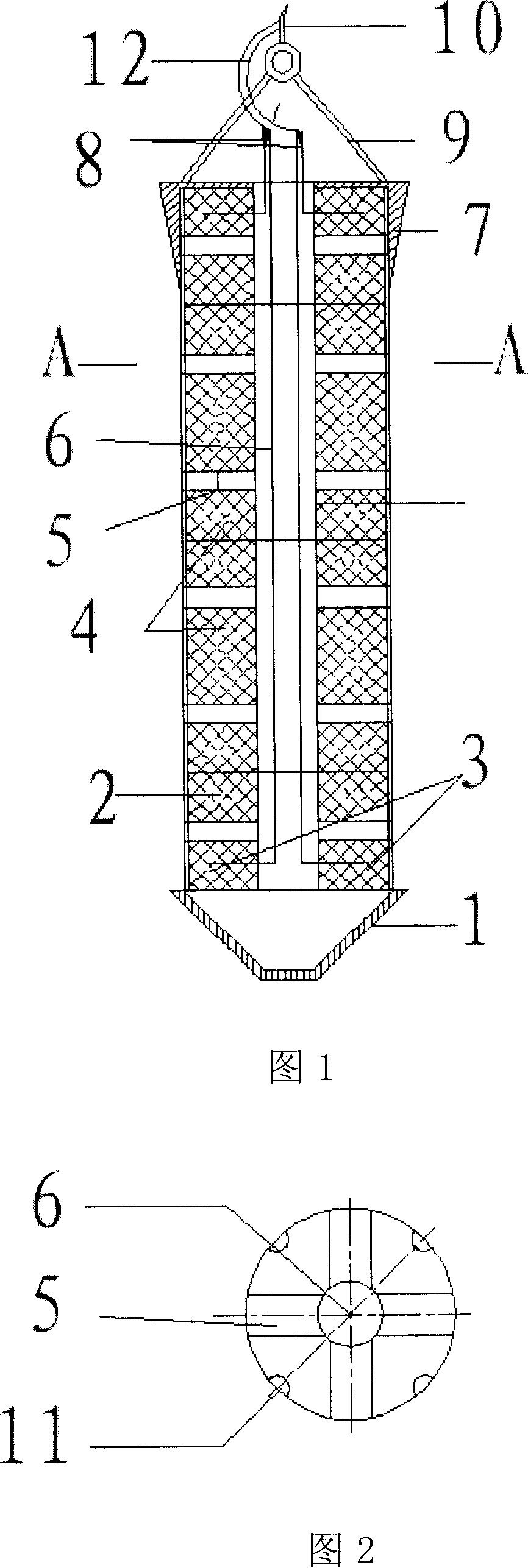

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

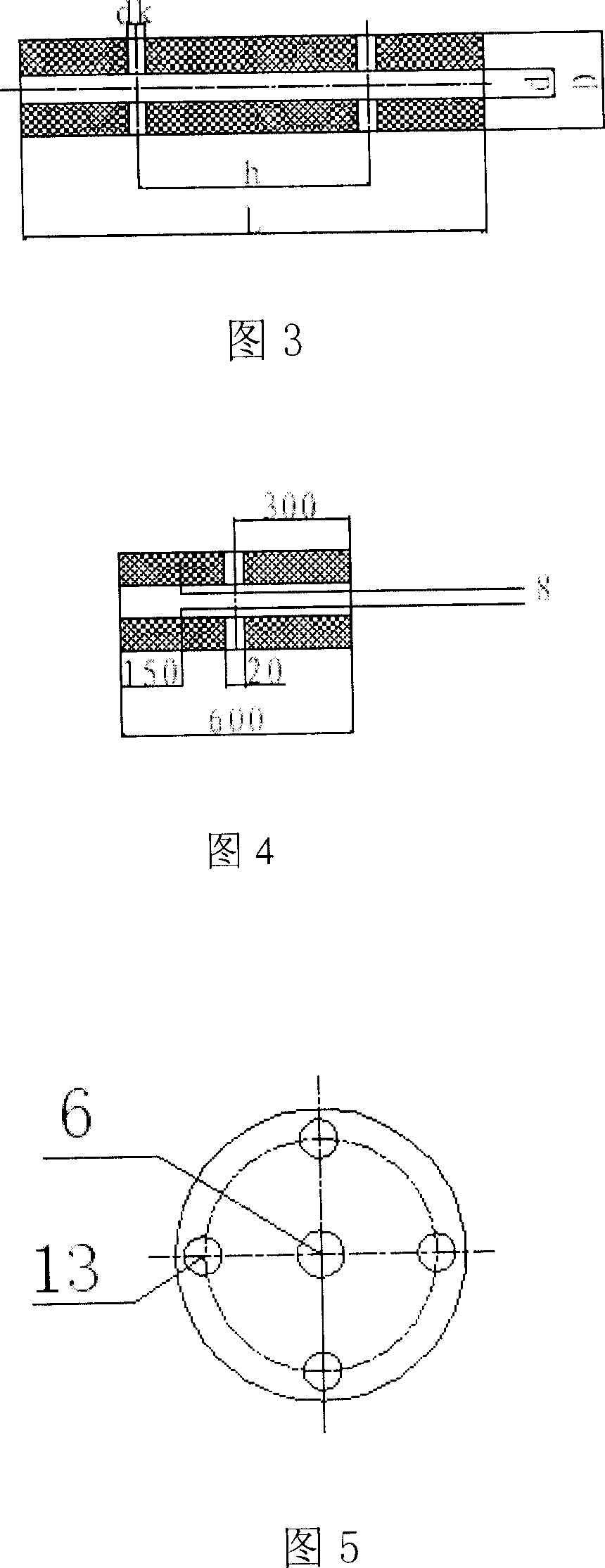

[0022] As shown in FIG. 1 , the preferred embodiment of the present invention includes two ignition powder columns 2 , two main charge columns 4 , a lower cover 1 , an upper cover 7 , two electric igniters 3 , steel ropes 9 and suspension rings 10 . Both the ignition charge and the main charge 4 are cylindrical charges cast by solid propellant, the charge has an axial center hole 6 and a radial through hole 5 and the outer wall has four mutually 90° The semicircular groove 11, the central hole 6 and the radial through hole 5 communicate with each other (see FIG. 2). According to Fig. 3, the diameter D=102mm of the powder column of the ignition powder column 2 and the main powder column 4, the length L=1.2mm of the single main powder column 4, the diameter d=30mm of the axial center hole 6, the radial The diameter d of the through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com