Single solid bowl type electrode measurement tube in high precision for water level of steam tank, and method for determining geometrical size

A technology of steam drum water level and geometric dimensions, which is applied in the direction of measuring devices, liquid level indicators for physical variable measurement, steam boilers, etc., can solve the problems of large measurement errors and poor sensing reliability, and achieve the effect of improving sampling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

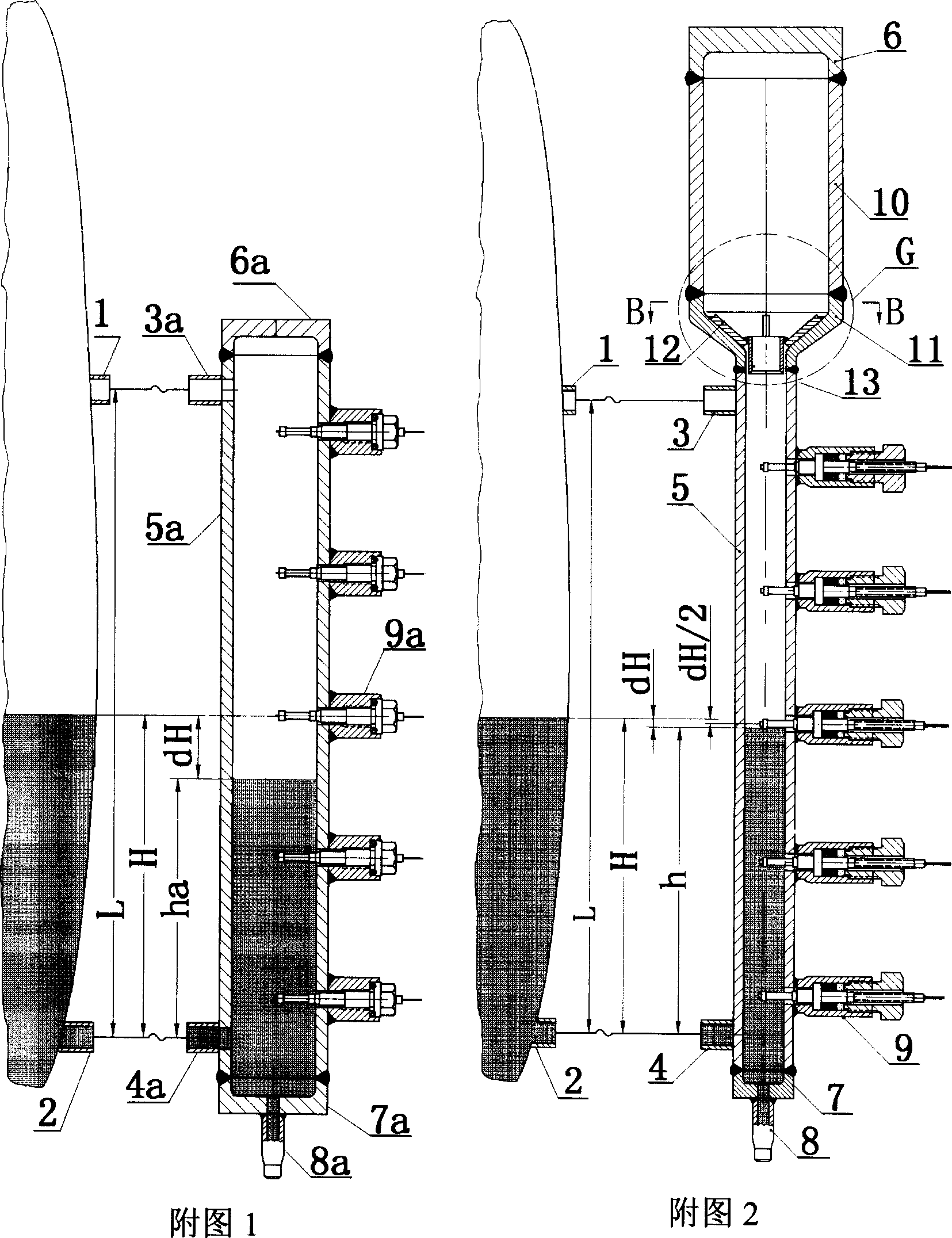

[0035] Accompanying drawing 1, 2 clearly shows the similarity and difference between the present invention and the traditional single cylinder straight cylinder measuring cylinder structure and sampling system of steam drum water level. The similarities: the steam and water sampling hole connectors 1 and 2 of the steam drum and the center distance L are consistent; the specifications of the steam and water sampling connectors 3a, 4a, 3 and 4 are the same, and they are respectively the same as the steam and water sampling ports on the steam drum. The measuring holes are connected; the center distance between the steam and water sampling pipes and the length of the steam and water sampling sections 5a and 5 are both L; the water chamber cylinder below the water sampling pipe has water end covers 7a and 7, and there is a sewage discharge pipe under the water end cover 8a, 8; and both contain electrode assemblies. The difference is that the distance between the steam sampling conn...

Embodiment 2

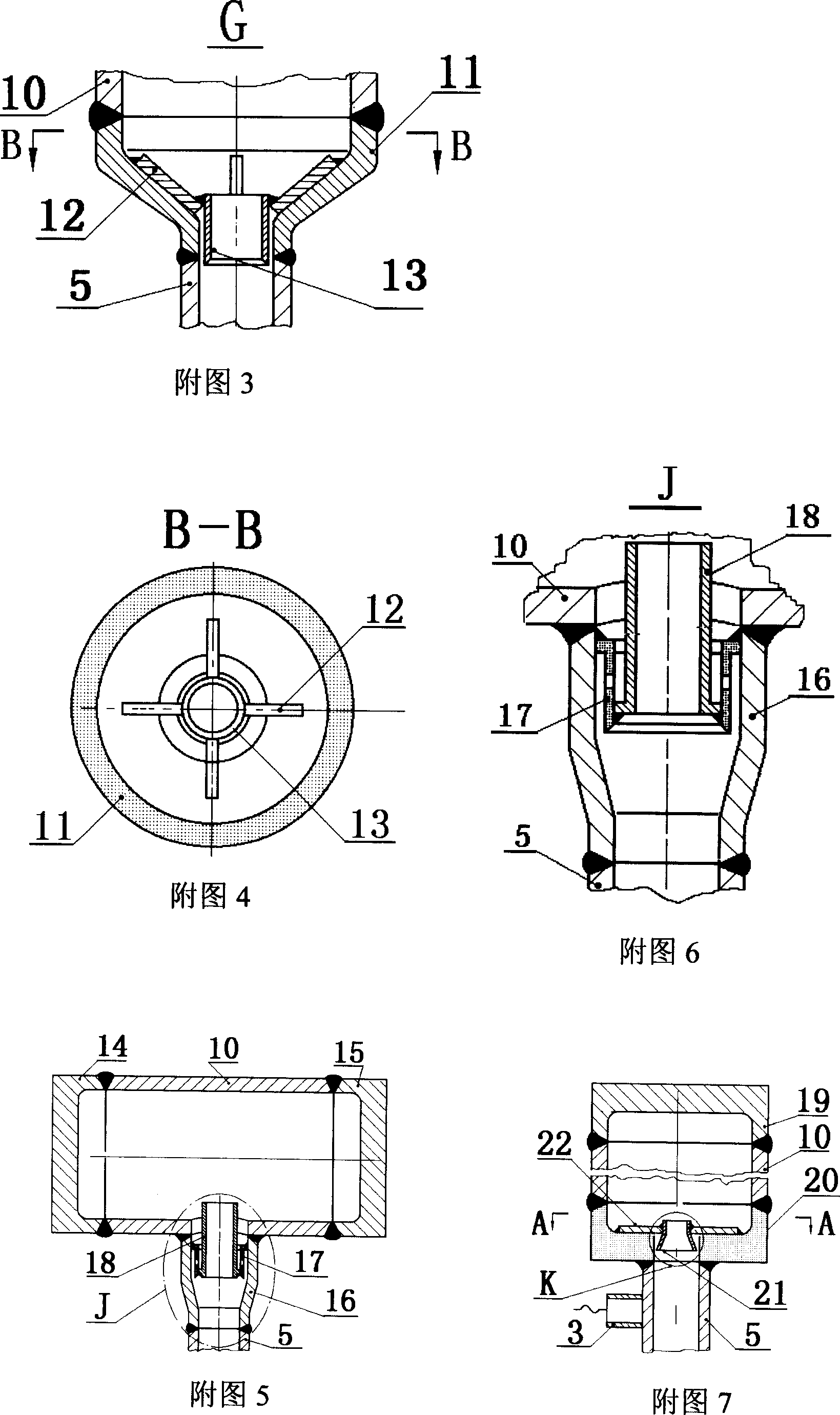

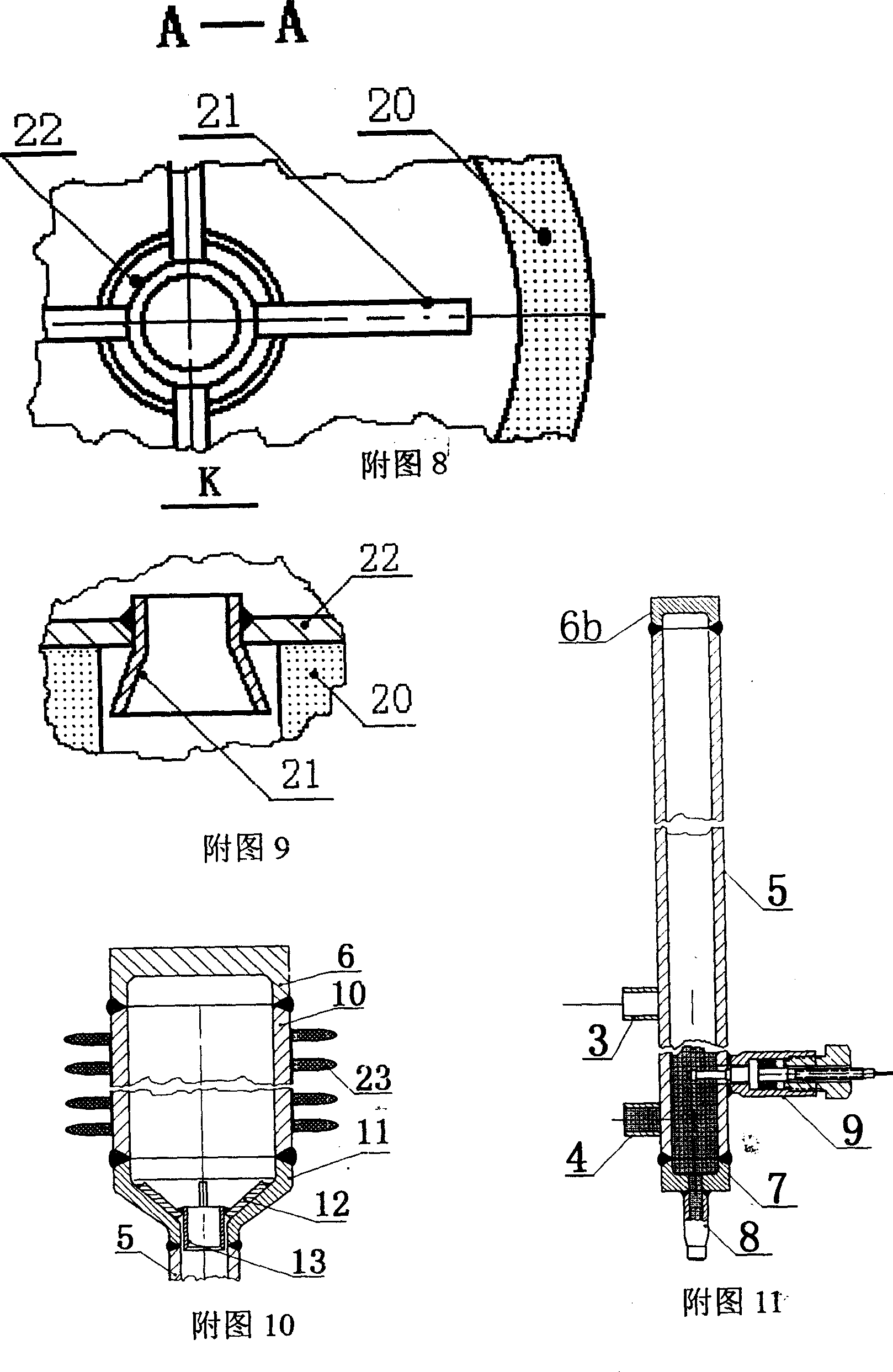

[0038] As shown in Figure 5, the large steam chamber is in a horizontal shape, and the axes of the large steam chamber cylinder body 10 and the measuring section cylinder body 5 are perpendicular to each other, which is a T-shaped large steam chamber fine water column electrode measuring cylinder. The two ends of the large steam chamber cylindrical body 10 are sealed by end caps 14,15. The through-flow anti-splash connecting pipe assembly at the connection between the cylinder body of the large steam chamber and the cylinder body of the measuring section is composed of a connection seat 16 , an equal-flow water cylinder 17 and a steam cylinder 18 . The shoulder plate on the top of the equalizing water tube 17 is connected to the connecting seat 16, the shoulder plate on the bottom of the venting tube 18 is connected to the inner wall of the lower part of the water tube 17, and the radial direction of the water tube 17 has a plurality of equiperipherally distributed small water ...

Embodiment 3

[0039] Embodiment 3, as shown in Figure 7, the large steam chamber adopts a straight cylinder type. The upper part of the cylinder body 10 of the large steam chamber is sealed by an end cover 19 . As shown in accompanying drawings 8 and 9, the through-flow anti-splash joint assembly at the junction of the cylinder body of the large steam chamber and the cylinder body of the measuring section is connected to the end cap 20 with a through-flow hole at the bottom, and the inside of the end cap 20 is provided with a trumpet tube 21 and 4 or 8 current equalizing grid bars 22 . Its flow hole diameter is equal to the inner diameter of the cylinder body 5 of the sampling section, and the flow equalizing grid bar 22 is vertically connected with the straight section of the trumpet tube 21 according to an equiperipheral angle. The saturated steam from the sampling cylinder 5 of the measurement section enters the large steam chamber through the flow hole of the end cover 20, and the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com