Color-recombination glass prism

A color prism and prism technology, applied in the optical field, can solve the problems of appearing in the image field of view, long intercept, affecting the image quality, etc., and achieve the effect of reducing the requirements of coating, reducing requirements and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings. Firstly, the accompanying drawings will be briefly described.

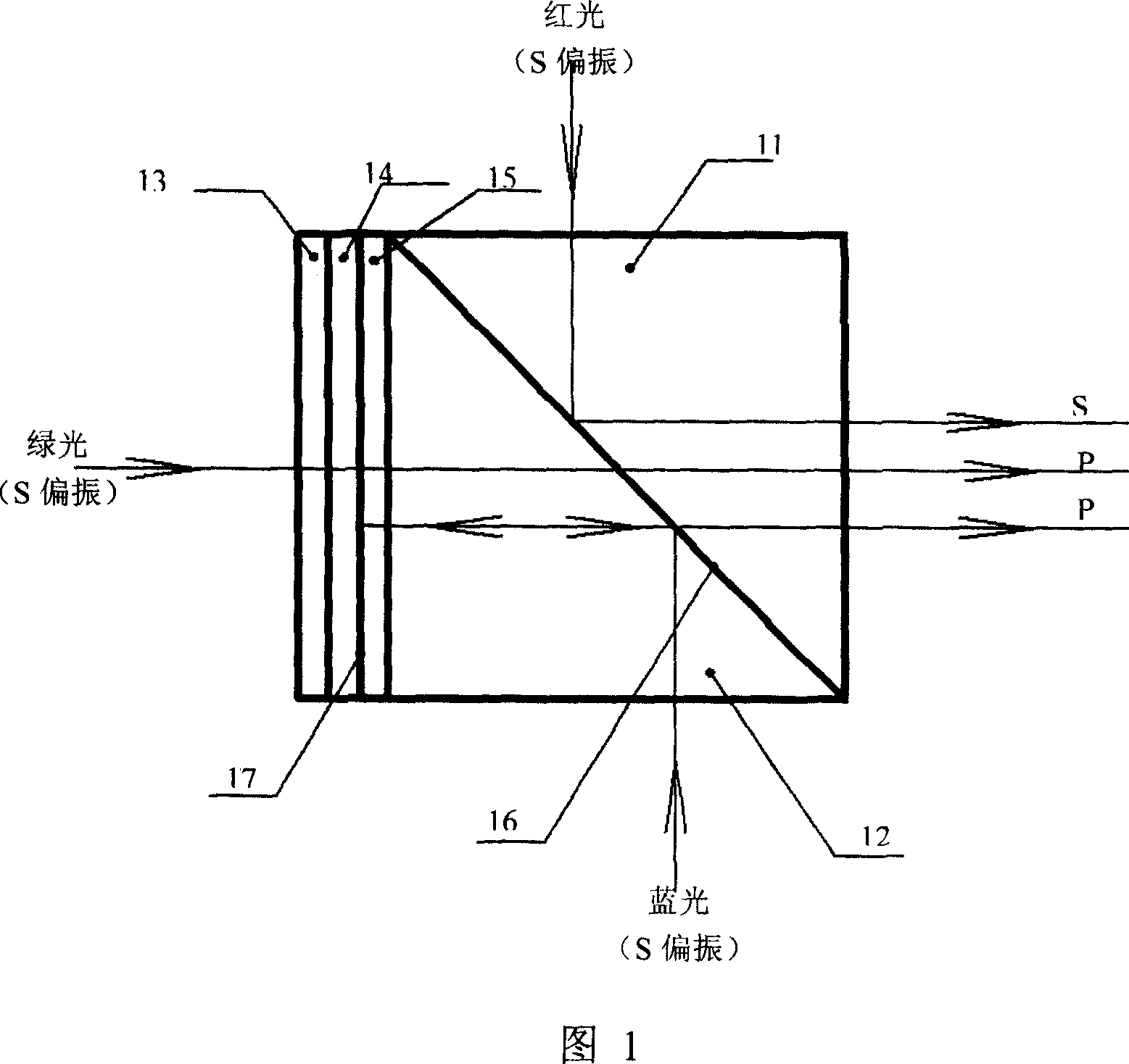

[0020] Fig. 1 is a color combining prism provided by the present invention. It mainly includes a right-angle prism 11 , a right-angle prism 12 , a quarter wave plate 13 , a quarter wave plate 15 , a bandpass filter substrate 14 , a polarizing beam splitting film 16 , and a beam splitting film 17 . The right-angle prism 11 and the right-angle prism 12 are glued together along the slope to form a square, and the slope of one of the right-angle prisms is coated with a polarization beam splitting film 16, and any side of the glued square is sequentially glued from the inside to the outside. A quarter wave plate 15, a bandpass filter 14 and a quarter wave plate 13. In Fig. 1, the rectangular prism 11 and the rectangular prism 12 are glued together to form a square prism along the slope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com