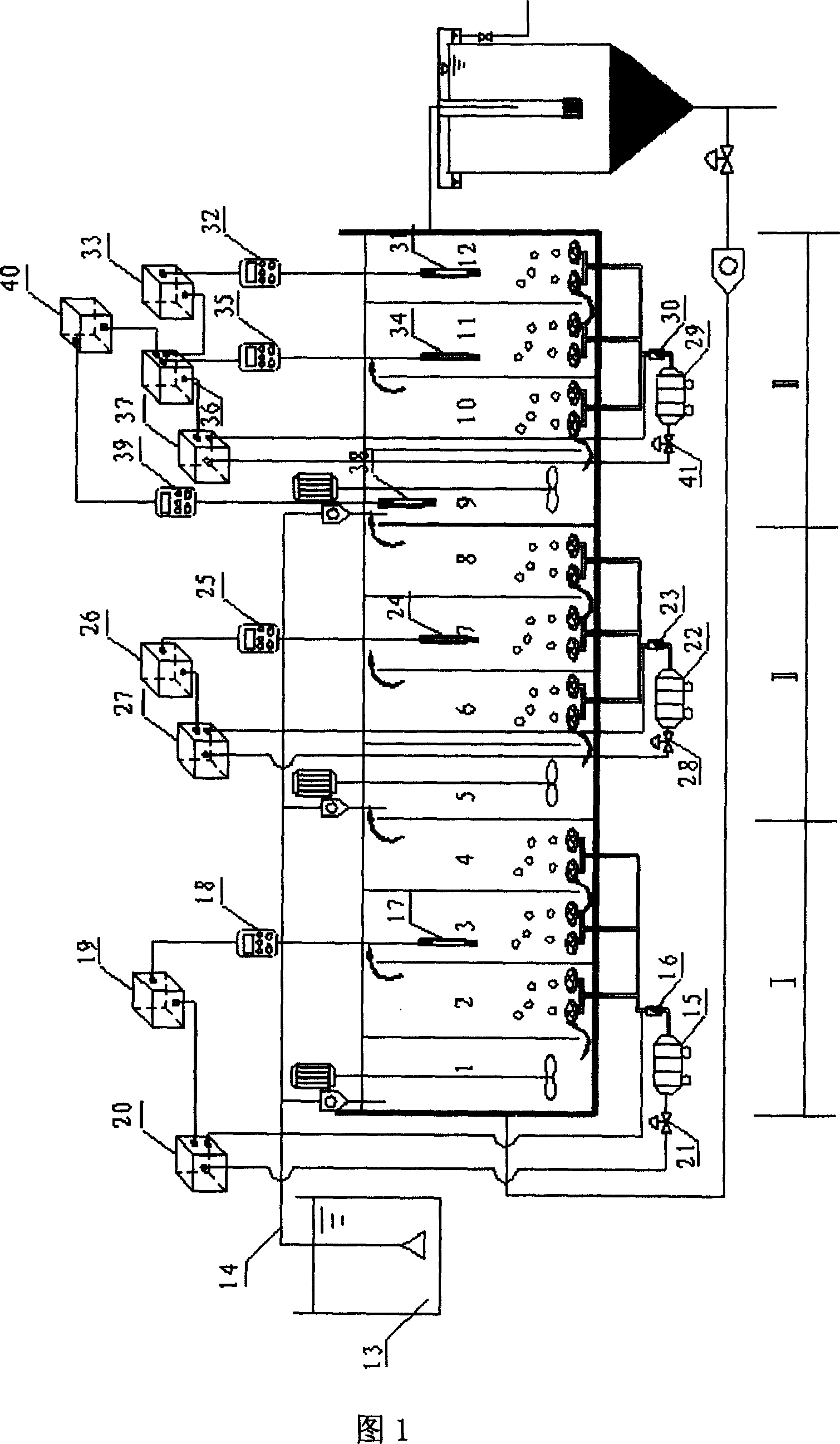

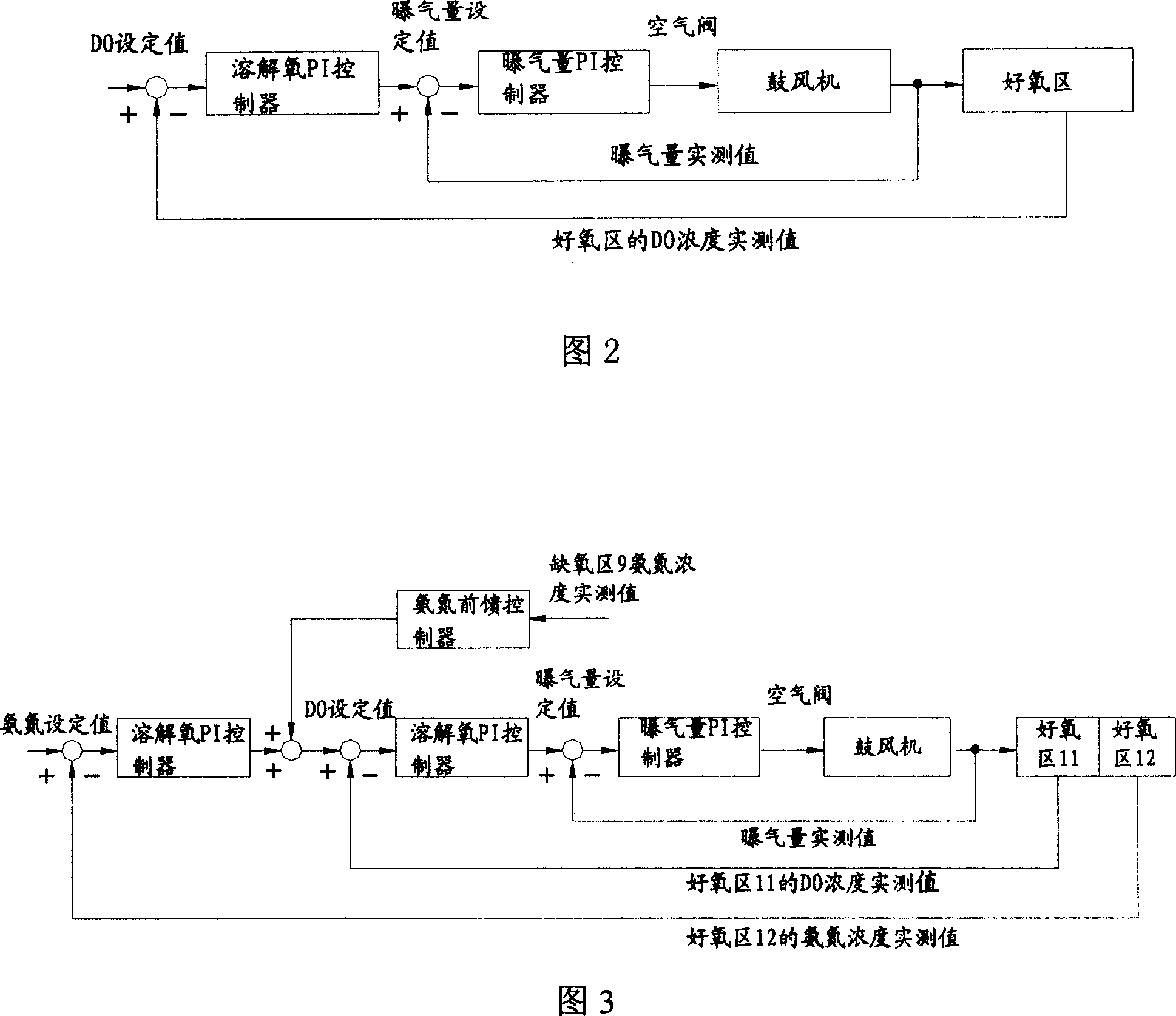

Low-oxygen aeration control device and method for subsection water inflow A/O biological denitrification technique

A technology of biological denitrification and low oxygen aeration, which is applied to the low oxygen aeration control device of the staged influent A/O biological denitrification process and its field, can solve the problems of sensitive load changes, large energy consumption for aeration, waste of energy and the like , to achieve the effect of avoiding insufficient aeration and avoiding over-aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In combination with the embodiments, the method for controlling low oxygen aeration of the present invention is:

[0036] Take the actual domestic sewage discharged from the family area of a university as the experimental object (COD=140~290mg / L, TN=35~80mg / L). The adopted multi-stage influent A / O biological denitrification reactor dissolves 300L and is divided into 3 stages, each with a volume of 100L. The system is equipped with 3 air compressors, the maximum air output is 2m3 / h, and the minimum air output is 0. The reactor first carries out sludge culture and domestication. After the domestication, the sludge concentration of each stage is: the first stage is 5~5.5g / L, the second stage is 4~4.5mg / L, and the third stage is 2.8~3.2mg / L. L. The daily treatment water volume of the reactor is 900L, the first stage water intake is 11.2L / h, the second stage water intake is 15L / h, and the third stage water intake is 11.2L / h. The reaction temperature is 20°C.

[0037] At the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com