Structure of bridge deck having polymer porous concrete surface course and construction method therefor

A technology of porous concrete and construction method, used in bridges, bridge parts, bridge materials, etc., can solve problems such as early damage, high noise, easy water accumulation on the bridge deck, etc., and achieve enhanced deformation capacity, excellent mechanical properties, and corrosion resistance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] An example below:

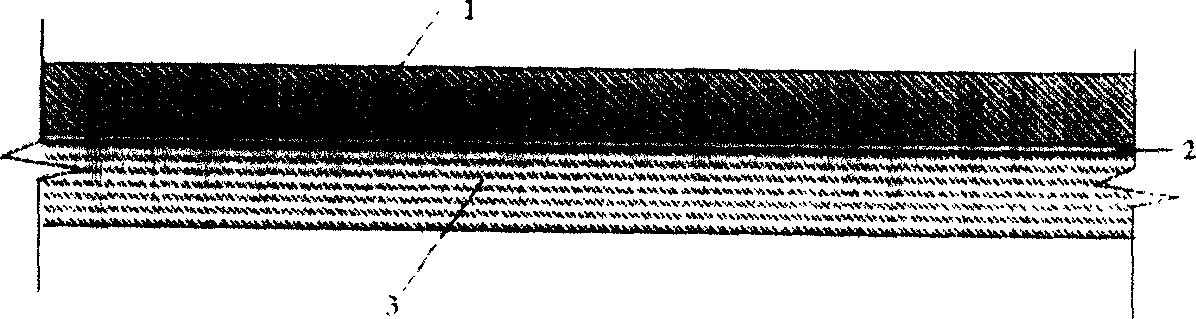

[0027] Its structure is: a bridge deck 3, a bonding layer 2, and a polymer porous concrete surface layer 1, the bridge deck 3 has a bonding layer 2, and the bonding layer 2 has a polymer porous concrete surface layer 1. The bridge deck 3 is a concrete bridge deck or a bridge deck paved with asphalt concrete. The bonding layer 2 is a polymer, or a composite material composed of a polymer and a filler, and can be firmly bonded to the bridge deck 3 below it and the polymer porous concrete surface layer 1 thereon. The polymer porous concrete surface layer 1 is a polymer porous concrete material, which is composed of discontinuously graded or single graded crushed stones, fillers, and polymers. The weight ratio of polymer porous concrete per cubic meter is—polymer:filler : gravel = 50~200: 0~500: 1200~2200. Bonding layer and polymer The polymer in the porous concrete is polymer resin, powder or emulsion, and corresponding diluent and water can be added,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com