Straight line driving screw pump oil production system

A technology of linear drive and oil production system, applied in pump, production fluid, earthwork drilling and other directions, can solve the problems of mismatched power driving mode, scrapped power driving device, waste of resources, etc., and achieves simple structure, resource saving and cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

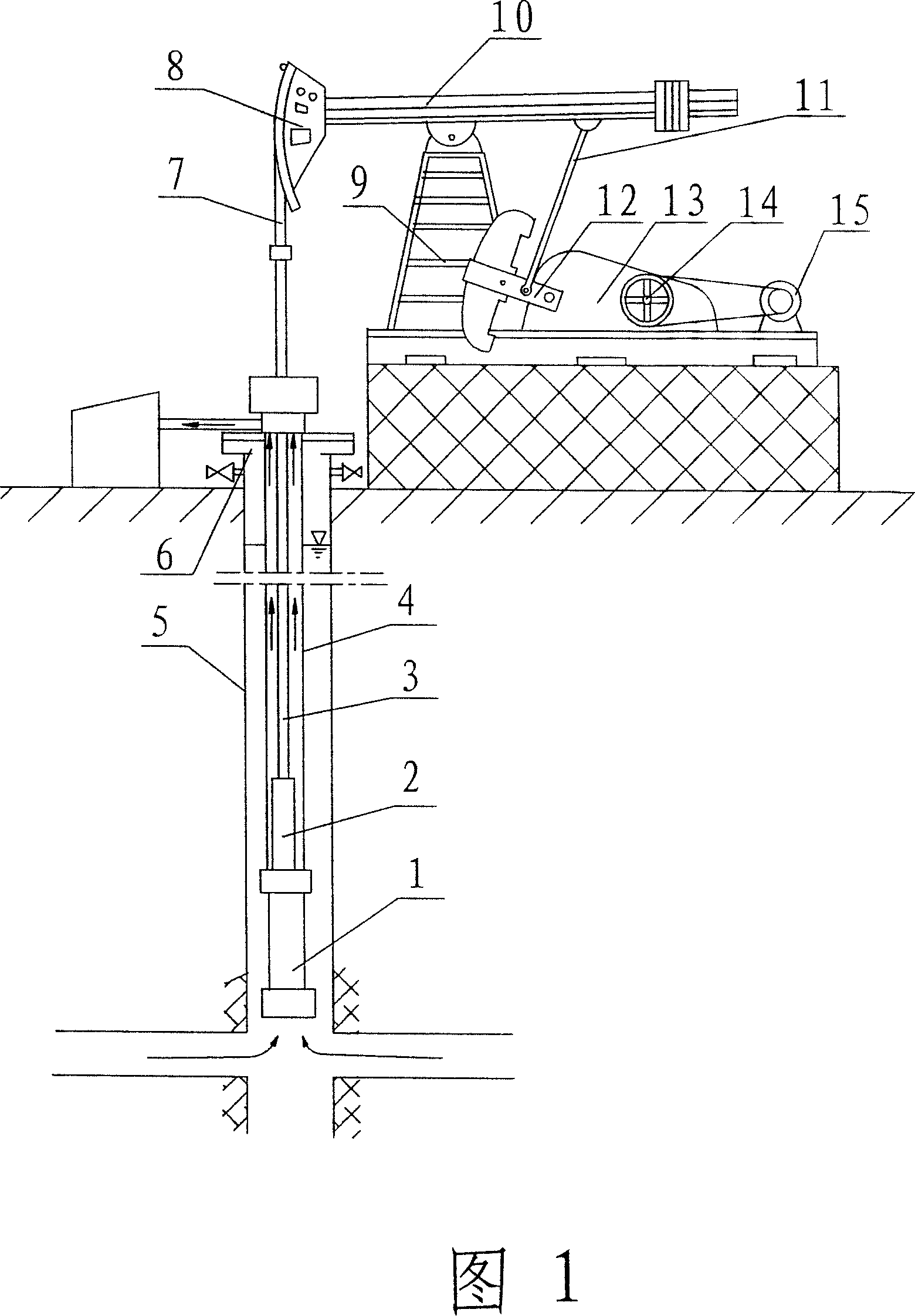

[0023] Figure 1 is an example of beam pumping unit, which mainly includes screw pump 1, power conversion mechanism 2, sucker rod 3, tubing 4, casing 5, wellhead 6, rope hanger 7, donkey head 8, and pumping unit Frame 9, beam 10, connecting rod 11, crank 12, speed reducer 13, belt pulley 14 and power machine 15 etc.

[0024] The power machine 15 drives the belt pulley 14 on the input shaft of the reducer to rotate through the belt transmission, after the reducer 13 decelerates, the output shaft of the reducer drives the crank 12 to rotate, and then through the connecting rod 11 in the crank linkage mechanism, the swing rod is The beam 10 reciprocates relative to the pumping frame 9, and the sucker rod 3 moves up and down linearly through the donkey head 8 and the rope hanger 7, and then through the power conversion mechanism 2 in this system, the sucker rod The reciprocating linear motion of 3 is converted into rotary motion, thereby driving the rotor of the screw pump to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com