Chip with light protection layer

A light protection and chip technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of large total chip thickness, high cost, erosion, etc., and achieve the effect of high reflectivity and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

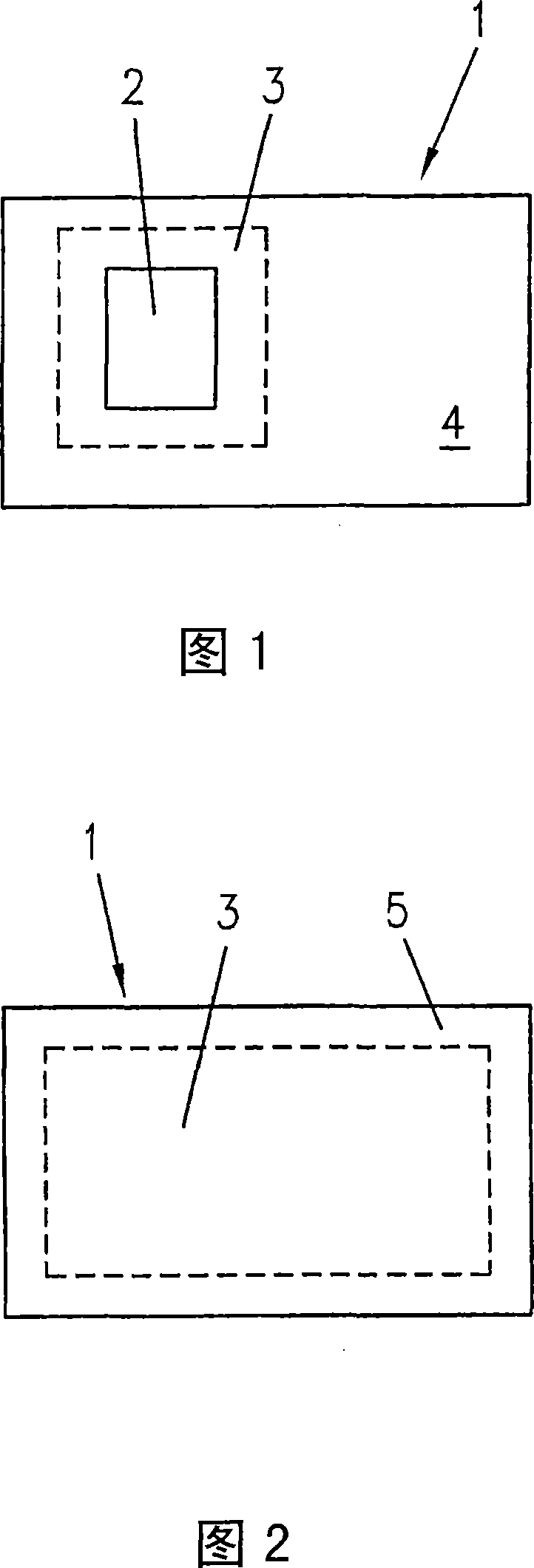

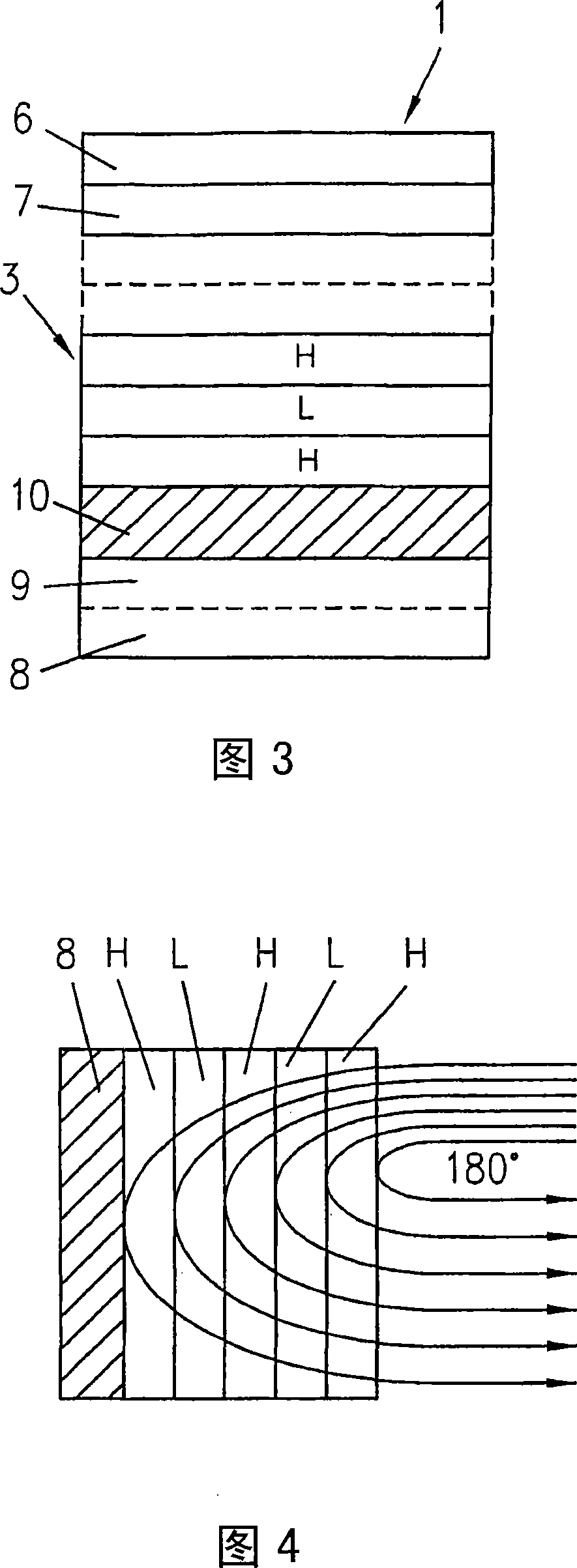

[0022] FIG. 1 shows a chip 1 according to the invention, with an integrated circuit 2 . In principle, several integrated circuits 2 can be realized on the chip 1 independently of one another. The integrated circuit 2 is implemented on a first side 4 of the chip 1 , commonly referred to as the "active side", and is protected from the effects of light by a dielectric mirror coating 3 applied to the surface of the chip 1 .

[0023] From the literature, a relatively wide variety of dielectric mirror coatings have been known to those skilled in the art for a considerable time. All dielectric mirror coatings generally share the fact that they consist of two or more dielectric λ / 4 layers, the adjacent dielectric layers having different refractive indices. Regarding dielectric mirror coatings, the reader is referred to Matt Young, "Optik Laser, Welleleiter", Springer, 1997; pp 160-161 as an example. Despite this fact, experts in the field of integrated circuit chips have never sugge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com