Production of multifunctional TiO2 modified light catalyst

A photocatalyst and multifunctional technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of reduced catalyst activity, increased carrier recombination centers, and unsatisfactory effects. Inhibit the effect of compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

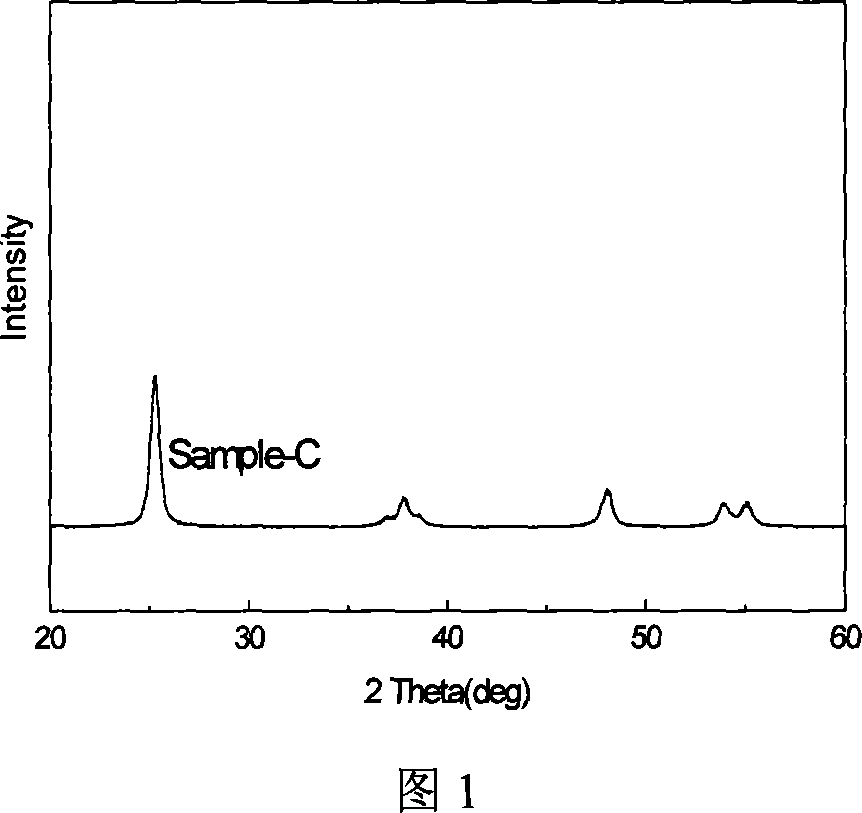

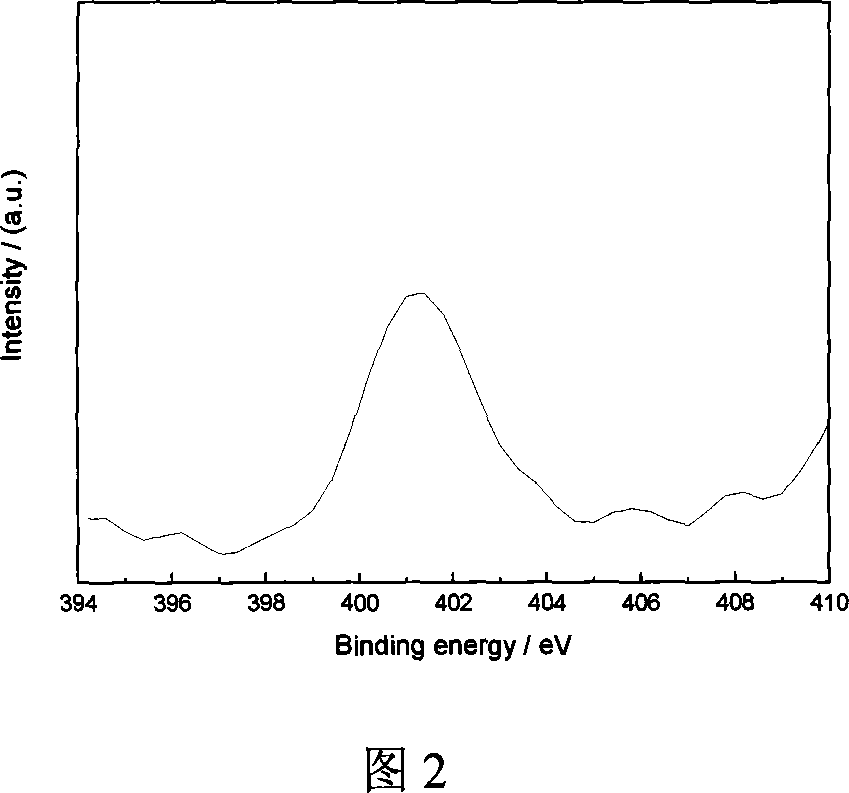

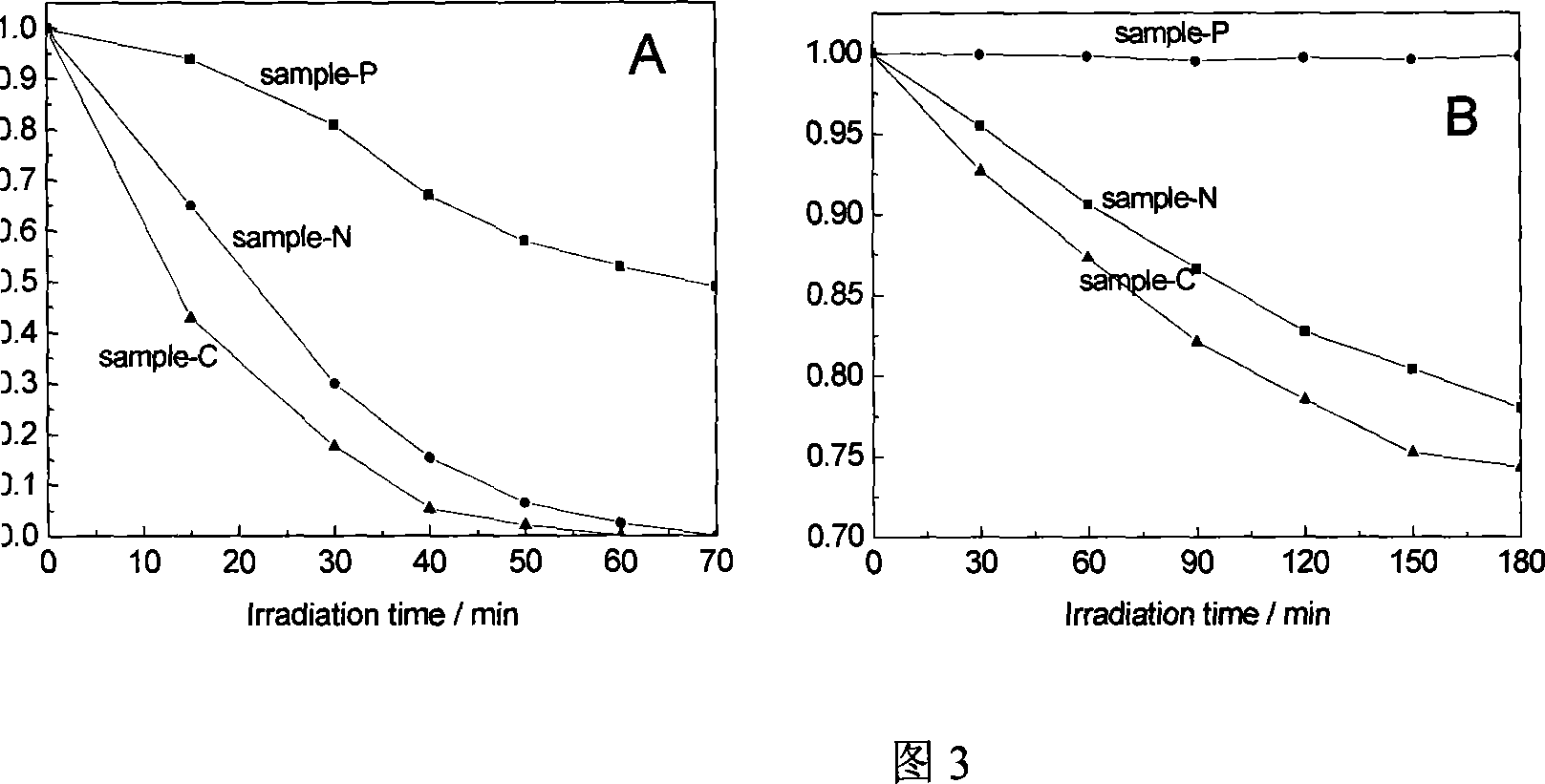

[0028] According to the amount of 0.01% (in terms of molar ratio of titanium), weigh quantitative iron nitrate (Fe(NO 3 ) 3 .9H 2 O) move into 100ml volumetric flask, add dehydrated alcohol to constant volume simultaneously, be mixed with the alcoholic solution A of iron; 5ml dehydrated alcohol is added the Ti(OBu) of 10ml 4According to the required Fe / Ti ratio, 2ml of solution A of corresponding concentration was dropped into solution B under stirring conditions to form solution C. Slowly add 10ml of 28% concentrated ammonia water into the solution C dropwise under vigorous stirring, and continue stirring for 12 hours after the dropwise addition is completed to ensure the completion of the reaction. The solution obtained after stirring was transferred to a drying oven at 105° C. for 24 h to constant weight. Transfer the powder sample into a crucible and place it in a muffle furnace, heat up to 350°C at a rate of 10°C / min and roast for 2 hours to obtain nitrogen and iron co...

Embodiment 2

[0030] According to the amount of 0.01% (in terms of molar ratio of titanium), weigh quantitative iron nitrate (Fe(NO 3 ) 3 .9H 2 O) move into 100ml volumetric flask, add dehydrated alcohol to constant volume simultaneously, be mixed with the alcoholic solution A of iron; 10ml dehydrated alcohol is added the Ti(OBu) of 10ml 4 After 60 min of sealed magnetic stirring in the solution, solution B was prepared; according to the required Fe / Ti ratio, 1ml of solution A of corresponding concentration was dropped into solution B under stirring conditions to form solution C. Slowly add 10ml of 28% concentrated ammonia water into the solution C dropwise under vigorous stirring, and continue stirring for 24 hours after the dropwise addition is completed to ensure the completion of the reaction. The solution obtained after stirring was transferred to a drying oven at 105° C. for 48 h to constant weight. Transfer the powder sample into a crucible and place it in a muffle furnace, heat u...

Embodiment 3

[0032] According to the amount of 0.01% (in terms of molar ratio of titanium), weigh quantitative iron nitrate (Fe(NO 3 ) 3 .9H 2 O) Move it into a 50ml volumetric flask, add dehydrated ethanol to constant volume at the same time, and prepare the alcohol solution A of iron; according to the required Fe / Ti ratio, add 10ml of Ti(OBu) under the stirring condition of solution A of 2ml corresponding concentration 4 After 15 minutes of sealed magnetic stirring in the preparation solution B;. Slowly add 10ml of 28% concentrated ammonia water into the solution B dropwise under vigorous stirring, and continue stirring for 6 hours after the dropwise addition is completed to ensure the completion of the reaction. The solution obtained after stirring was transferred to a drying oven at 105° C. for 48 h to constant weight. Transfer the powder sample into a crucible and place it in a muffle furnace, heat up to 400°C at a rate of 10°C / min and roast for 2 hours to obtain nitrogen and iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com