Foam systems , packages and their applications

A foam material and reactant technology, applied in foam material systems, bags and its application fields, can solve the problems of slow, uneven foaming, uneven hardening, etc., and achieve the effect of avoiding demixing, fast hardening, and uniform foam consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Foam System

[0059] The weight-parts from which the components of the foam system of the present invention are made up (the respective components are made by mixing the ingredients) are given below:

[0060] Component 1:

[0061] Geniosil SLM 414000* 70 parts

[0062] 1 part dibutyltin laurate

[0063] Silbyk 9210** 2 servings

[0064] Calcium carbonate 6 parts

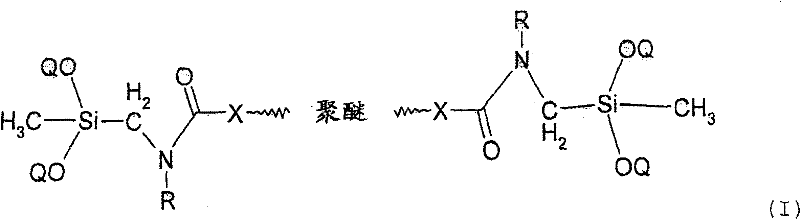

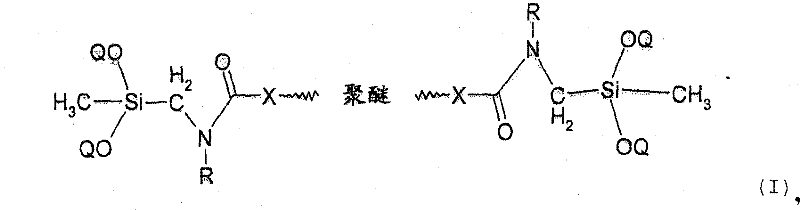

[0065] *) Geniosil SLM 414000 is a dimethoxy(methyl)silylmethylcarbamate-terminated polyether of the formula (I) from the company Wacker Chemie, München, Deutschland, X in the formula (I) is O, R is hydrogen (CAS-Nr.611222-18-5)

[0066]**) Silbyk 9210 is a polyether-modified polysiloxane belonging to BYK-Chemie GmbH, Altana Chemie AG, Wesel, Deutschland.

[0067] Component 2:

[0068] 8 parts water

[0069] Citric acid, monohydrate 13 parts

Embodiment 2

[0070] Example 2: Two-component-pack

[0071] The components of Example 1 were filled into each chamber of the double-chamber-box one by one, and the chamber was closed. The box is suitable for housing a static-mixer which may belong to a bag.

Embodiment 3

[0072] Example 3: Application of the foam system

[0073] The components of the foam system were mixed and filled into the cavities with a spatula (Spachtel). Causes foaming and hardening to form a foam material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com