Method for microfining organic pigment of color filter

A color filter and organic pigment technology, applied in the field of miniaturization, can solve the problems of poor stability and wide particle size distribution range, and achieve the effects of high stability, good fluidity and avoiding adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

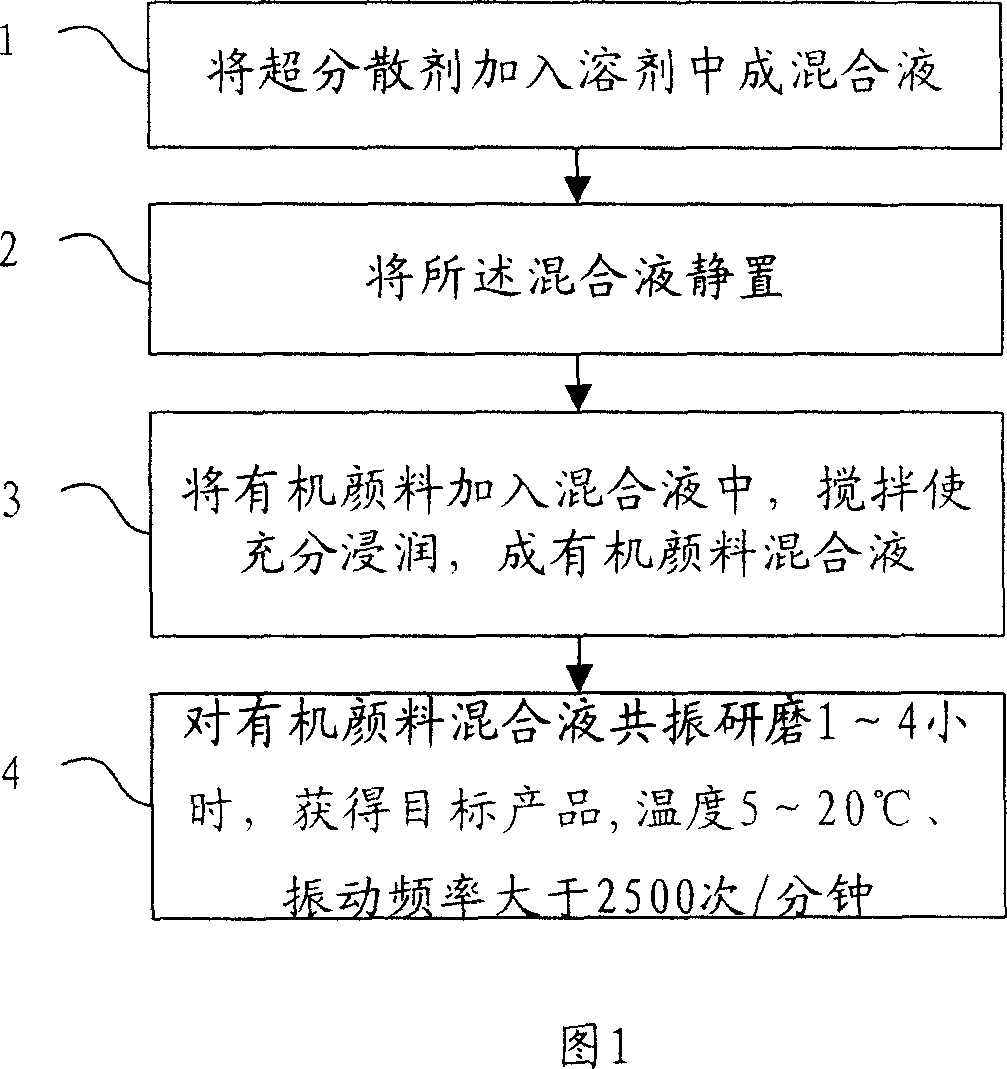

Method used

Image

Examples

Embodiment 1

[0048] Micronization of DPP red pigment using EFKA4047 hyperdispersant:

[0049] (1) Add 12g EFKA4047 hyperdispersant to 200g solvent to make a mixed solution;

[0050] (2) leave the mixed solution for 3 hours;

[0051] (3) 20g DPP red pigment is added in the mixed solution;

[0052] (4) stirring into an organic pigment mixed solution;

[0053] (5) Put the organic pigment mixture into the grinding cylinder, drive the grinding and stirring blades to rotate at a speed of 4500 rpm, drive the grinding cylinder to vibrate axially at a frequency of 2600 times per minute, and keep the inner cavity temperature of the grinding cylinder at 15°C temperature, and grind for 1.5 hours to obtain the target product.

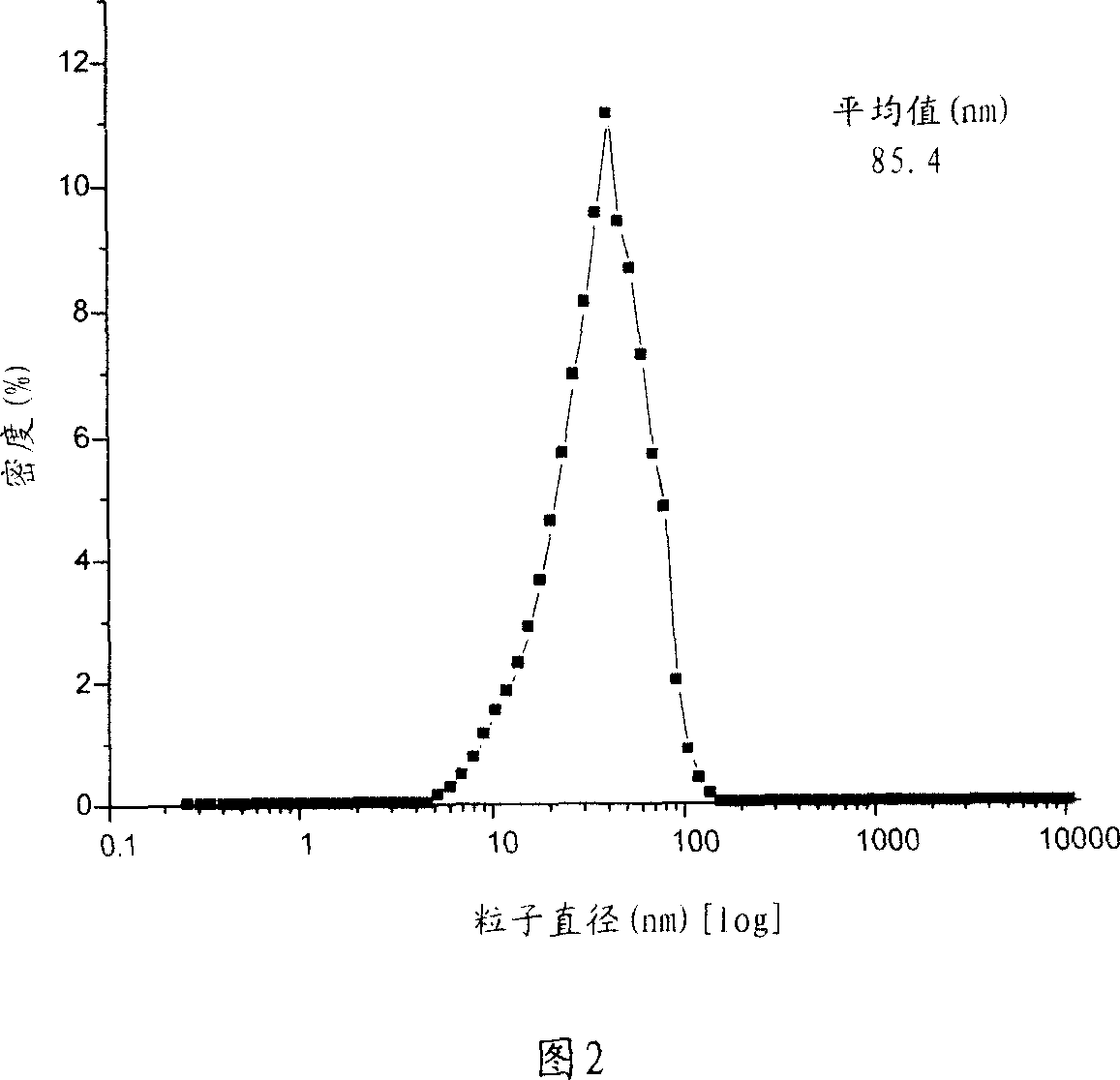

[0054] The particle size distribution of the pigment was tested with a nanoparticle size analyzer, and the test results are shown in Figure 2.

Embodiment 2

[0056] Micronization of Phthalocyanine Blue Pigment Using TA-100 Hyperdispersant:

[0057] (1) 10g TA-100 hyperdispersant is dissolved in 50g solvent to make a mixed liquid;

[0058] (2) leave the mixed solution for 3.5 hours;

[0059] (3) 45g phthalocyanine blue pigment is added in the mixed solution;

[0060] (4) stirring into an organic pigment mixed solution;

[0061] (5) Put the organic pigment mixture into the grinding cylinder, drive the grinding and stirring blades to rotate at a speed of 4500 rpm, drive the grinding cylinder to vibrate axially at a frequency of 2600 times per minute, and keep the temperature of the inner cavity of the grinding cylinder at 10°C temperature, and grind for 1.0 hour to obtain the target product.

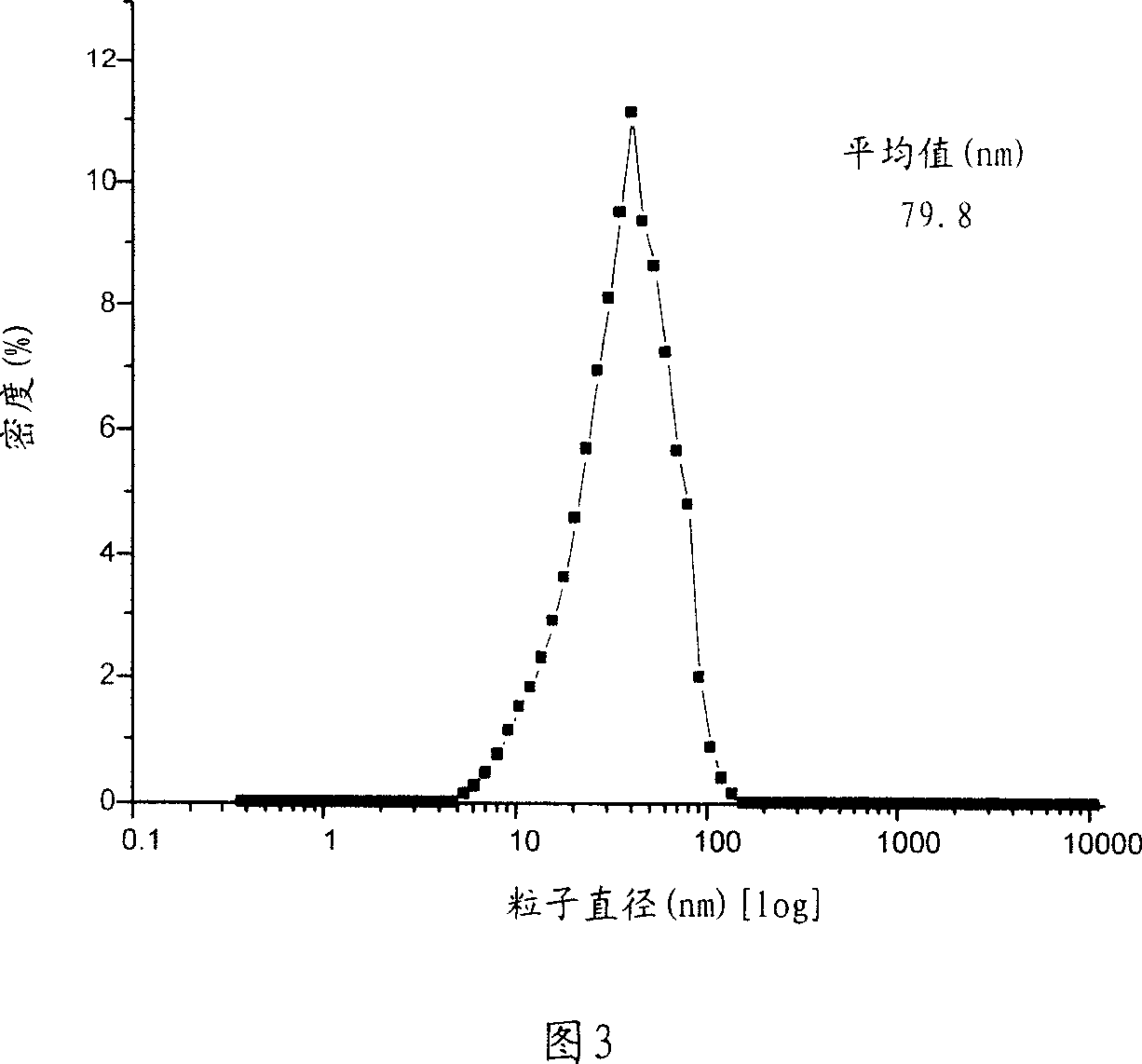

[0062] The particle size distribution of the pigment was tested with a nanoparticle size analyzer, and the test results are shown in Figure 3.

Embodiment 3

[0064] Micronization of DPP red pigments using TA-100 hyperdispersant:

[0065] (1) Add 23g TA-100 hyperdispersant to 400g solvent to form a mixed solution;

[0066] (2) the mixed solution is stirred by a magnetic stirrer;

[0067] (3) leave the mixed solution after stirring for 24 hours;

[0068] (4) 40g DPP red pigment is added in the mixed liquor;

[0069] (5) stirring into an organic pigment mixed solution;

[0070] (6) Add 26g resin in the organic pigment mixed solution;

[0071] (7) Put the above solution into the grinding cylinder, drive the grinding and stirring blades to rotate at a speed of 4500 rpm, drive the grinding cylinder to vibrate axially at a frequency of 2600 times per minute, and keep the temperature of the inner chamber of the grinding cylinder at 15°C. After grinding for 1.5 hours, the target product was obtained.

[0072] The particle size distribution of the pigment was tested with a nanoparticle size analyzer, and the test results are shown in Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com