Glue sprayer

A glue spraying machine and glue spraying technology, which is applied in the field of glue spraying machines, can solve the problems that the glue spraying machine is difficult to realize the glue spraying effect, and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

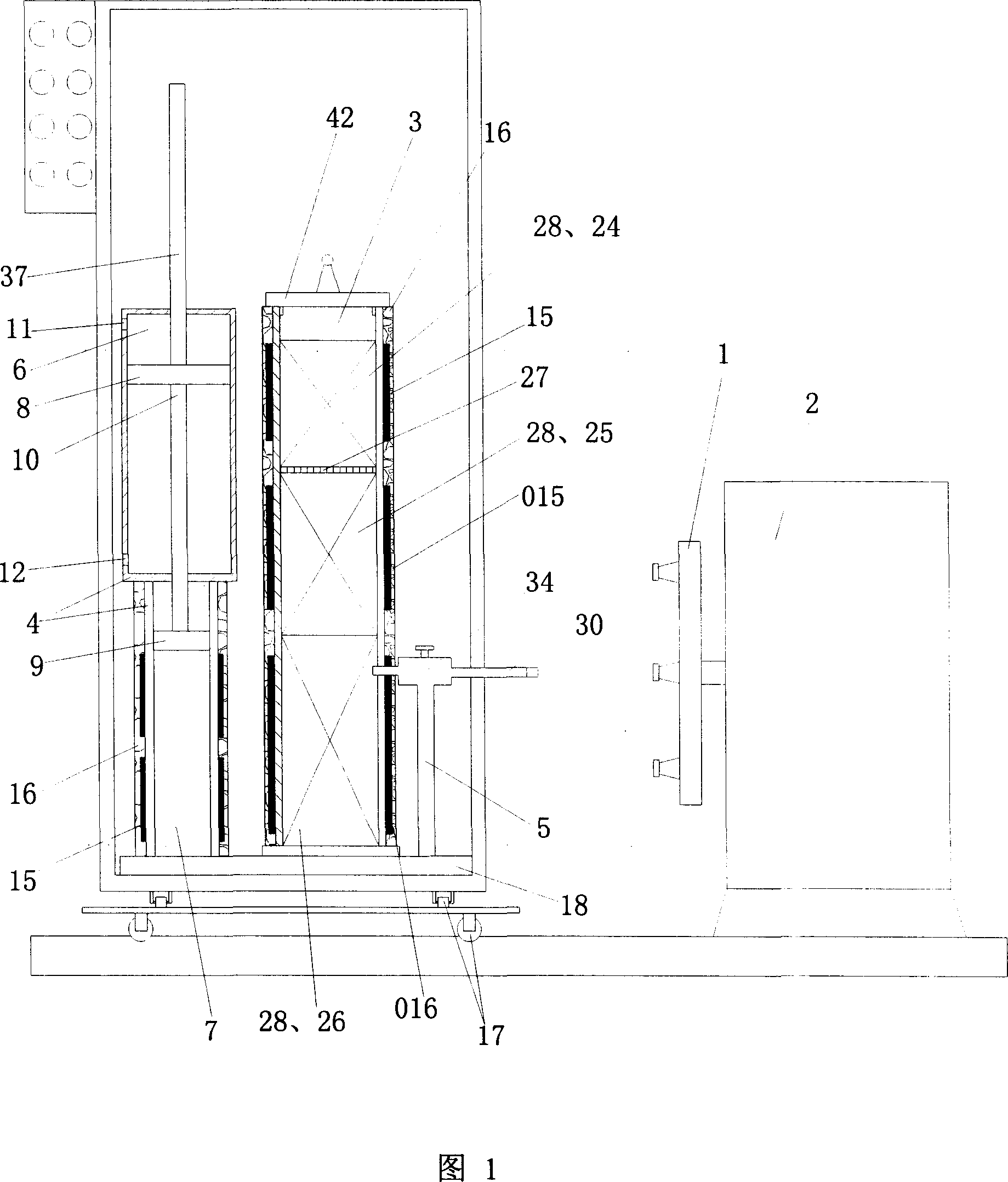

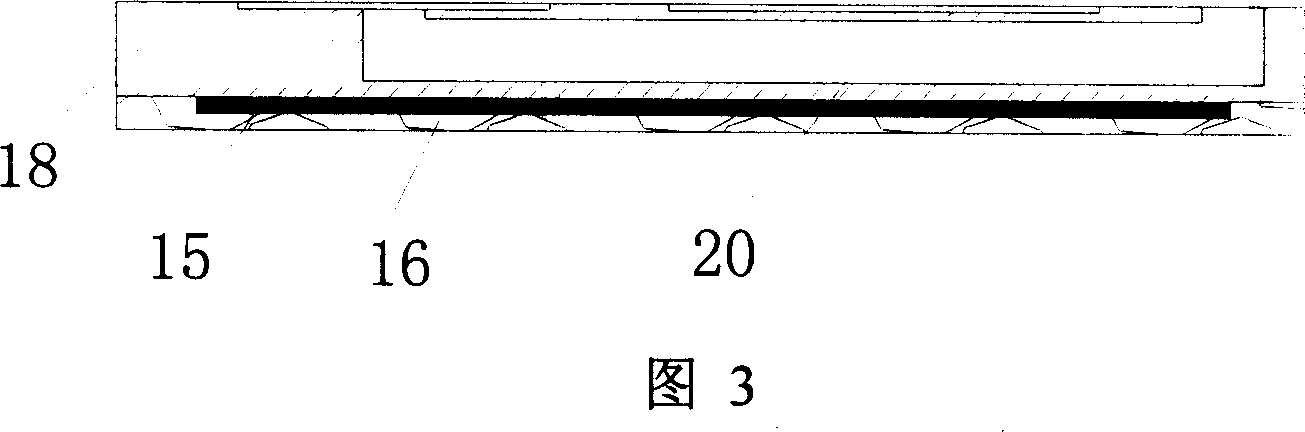

[0039] Fig. 1 shows the basic structure of a preferred embodiment of the present invention, a glue spraying machine, including a melt glue barrel 3, an air glue cylinder 4, a glue delivery pipe 5 and a nozzle mechanism. The air glue cylinder 4 includes a serially connected primary cylinder 6 and a secondary glue cylinder 7 wrapped with a heating layer 15 and an insulating layer 16. The bottom of the glue cylinder 7 communicates with the bottom of the melt glue barrel 3 through a first one-way valve 13. The glue tank 7 is connected to the rubber delivery pipe 5 through the second one-way valve 14, and the rubber delivery hose 5 is connected to the nozzle mechanism; the pipeline and the rubber delivery hose 5 connected to the melt glue barrel 3 and the air glue cylinder 4, and the nozzle mechanism are wrapped with a heating layer 15 And insulation layer 16. In order to facilitate the operation of the glue spraying machine in actual work, the glue spraying machine is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com