Air cleaning system in closed cabin and the control method

An air purification system and purification system technology, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of poor air purification effect, complex structure, and large volume of combustion devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

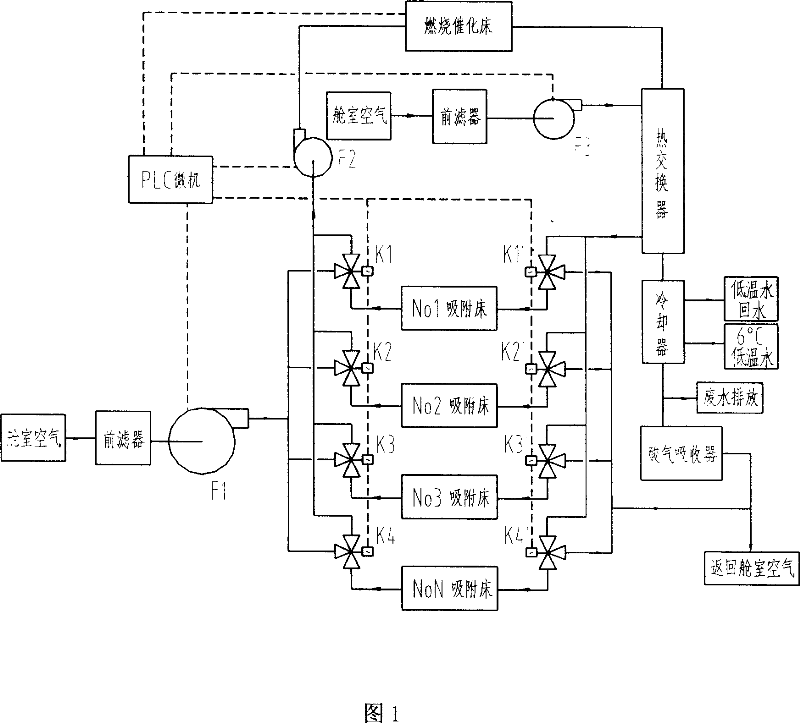

[0013] The present invention is made up of main air purification system, auxiliary air purification system and connection combination system, is characterized in that main air purification system is air adsorption purification system; auxiliary air purification system is catalytic combustion air purification system; connection combination system connects main air purification system It is organically connected with the auxiliary air purification system to form an air purification system that combines adsorption and catalytic combustion. The combined system can also be called a desorption regeneration system.

[0014] The main air purification system of the present invention is composed of a pre-filter, a fan armor and a multi-unit activated carbon fiber adsorption bed, and the number of the adsorption beds is set according to the required parameters; , resistance, weight of loaded adsorption material, adsorption time, desorption time and other settings, generally 3-7 unit adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com