Preparation method of potpourri type nano microcapsule essence

A nano-microcapsule and flower-flavored technology, which is applied in the field of preparation of floral-flavored essences, can solve the problems that the preparation methods of floral-flavored essences have not yet been reported in relevant reports, and achieve the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

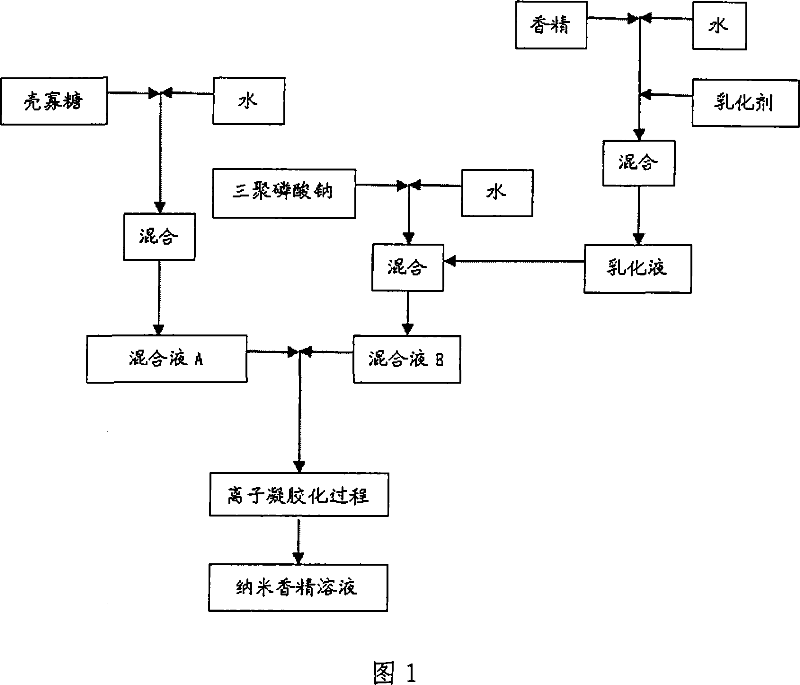

Image

Examples

Embodiment 1

[0017] Prepare 100 grams of nano essence

[0018] (1) Weigh 0.05g of chitosan oligosaccharide (CSO) on an electronic balance, add 49.95g of deionized water, and stir gently for 2 minutes to completely dissolve it.

[0019] (2) Weigh 0.0375g of sodium tripolyphosphate (TPP) on an electronic balance, add 49.5625g of deionized water, and stir gently until it dissolves. Then add 0.2g essence and 0.2g Tween 20. Put into a magnetic stirrer and emulsify for 30 minutes at a rotating speed of 500r / min.

[0020] (3) Pour all the prepared sodium tripolyphosphate (TPP) solution into an acid burette, and place the chitosan oligosaccharide (CSO) solution on a magnetic stirring table. Adjust the dropping speed and stirring speed of the burette so that the sodium tripolyphosphate (TPP) solution reacts with the chitosan oligosaccharide (CSO) solution at a speed of 500 r / min at a dropping speed of 2 d / s. until it drips completely.

Embodiment 2

[0022] Prepare 200 grams of nano essence

[0023] (1) Weigh 0.1 g of chitosan oligosaccharide (CSO) on an electronic balance, add 99.9 g of deionized water, and stir gently for 2 minutes to completely dissolve it.

[0024] (2) Weigh 0.075g of sodium tripolyphosphate (TPP) on an electronic balance, add 99.125g of deionized water, and stir gently until it dissolves. Then add 0.4g essence and 0.4g Tween 20. Put into a magnetic stirrer and emulsify for 30 minutes at a rotating speed of 500r / min.

[0025] (3) Pour all the prepared sodium tripolyphosphate (TPP) solution into an acid burette, and place the chitosan oligosaccharide (CSO) solution on a magnetic stirring table. Adjust the dropping speed and stirring speed of the burette so that the sodium tripolyphosphate (TPP) solution reacts with the chitosan oligosaccharide (CSO) solution at a speed of 500 r / min at a dropping speed of 2 d / s. until it drips completely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com