Small-sized Wind power generator and its assembly method

A wind-driven generator, a small-scale technology, applied in the direction of wind-driven engine, wind-driven motor combination, wind power generation, etc., can solve the problems of increased motor weight, reduced power generation effect, large axial size of the motor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

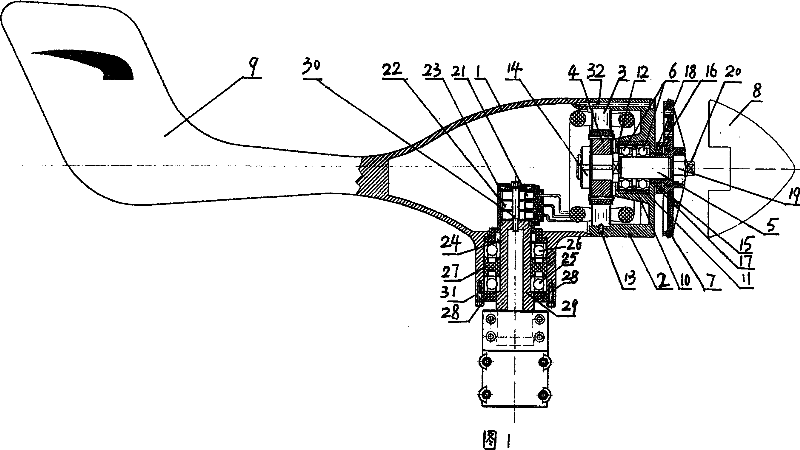

[0023] As shown in Figure 1, a small-sized wind power generator includes a rear seat 1, a motor casing 2, a stator 3, a rotor 4, a stainless steel rotor shaft 5, two first ball bearings 6 of type 205 supporting the rotor shaft 5, The hub disc 7 and the front cover 8 are equipped with wind rotor blades (not shown) on the front cover 8, and a tail rudder 9 is provided on the rear seat 1.

[0024] A conical first boss 10 is provided on the inner end surface of the motor casing 2 away from the rear seat 1 and toward the rear seat 1 , and the first boss 10 is coaxial with the motor casing 2 . A mounting hole for installing the first ball bearing 6 is provided in the first boss 10 , and the first ball bearing mounting hole is coaxial with the first boss 10 . A wear-resistant rubber ring 11 is provided along the inner side wall of the first ball bearing installation hole, and the two first ball bearings 6 are installed in the rubber ring 11 . On the inner sidewall in the first ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com