Method for treating industrial wastewater / sewage by two-stage magnetic isolation technique

A technical treatment and magnetic separation technology, applied in the fields of magnetic field/electric field water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of not involving industrial waste/sewage, slow processing speed, high operating cost, etc., and achieve economical Better effect, improved cleaning efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

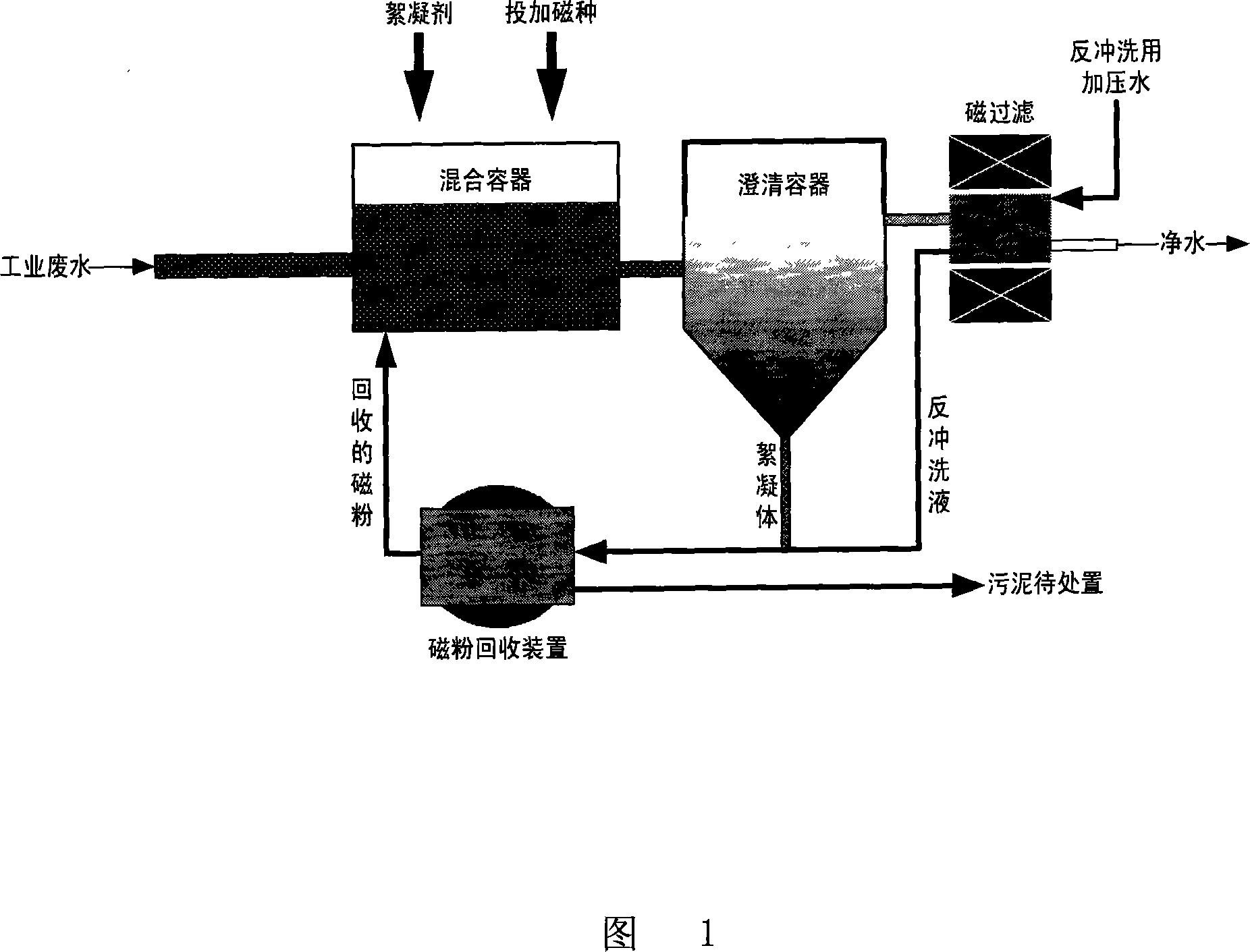

[0024] The present invention will be further described below in conjunction with accompanying drawing 1.

[0025] The waste water is pumped to the mixing container, and flocculant and magnetic powder are added into the mixing container at the same time, stirred continuously by the agitator to achieve the flocculation effect, and then sent to the clarification container for the first stage treatment, about 1-2 in the clarification container After about 10 minutes, the flocculated material settles at the bottom of the clarification container, and is transported to the magnetic drum recovery device of the permanent magnetic field through the pipeline; the separation and recovery of the magnetic seeds are carried out.

[0026] The liquid from the clarification container is then magnetically filtered through a high-gradient magnetic separator, and at the same time, the magnetized particles adsorbed on the filler of the separator are washed by degaussing and backwashing pressurized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com