Hanger bearing image-forming system and light scribing device

An imaging system and suspension technology, applied in the field of projection exposure, can solve the problems of increasing the overall mass and increasing the difficulty of design, and achieve the effects of reducing stiffness requirements, improving relative vibration modes, and strong anti-interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

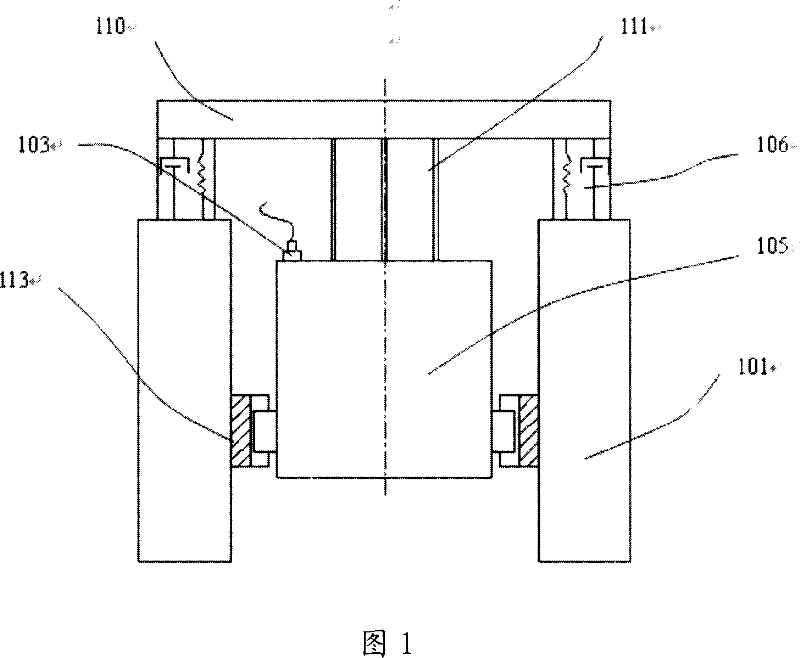

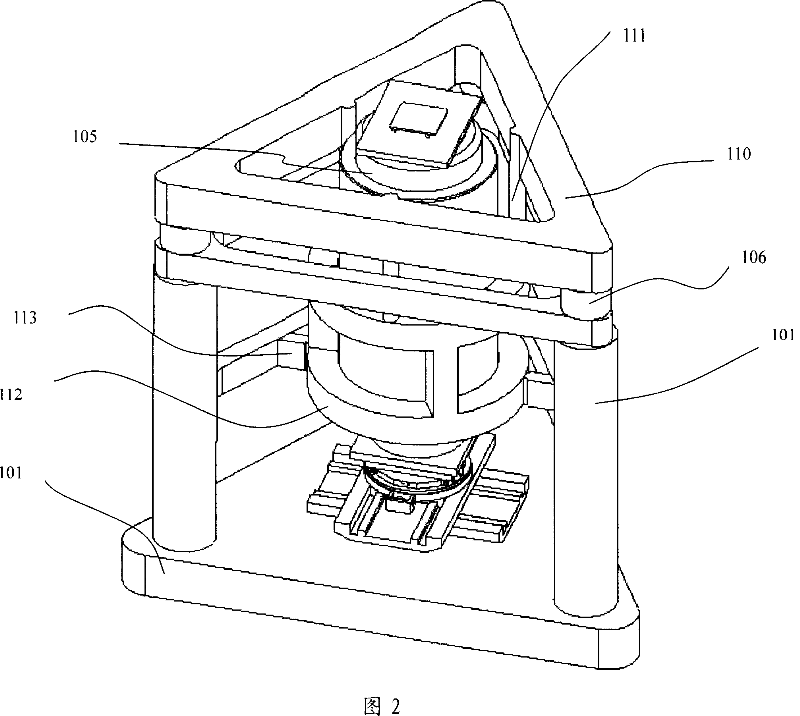

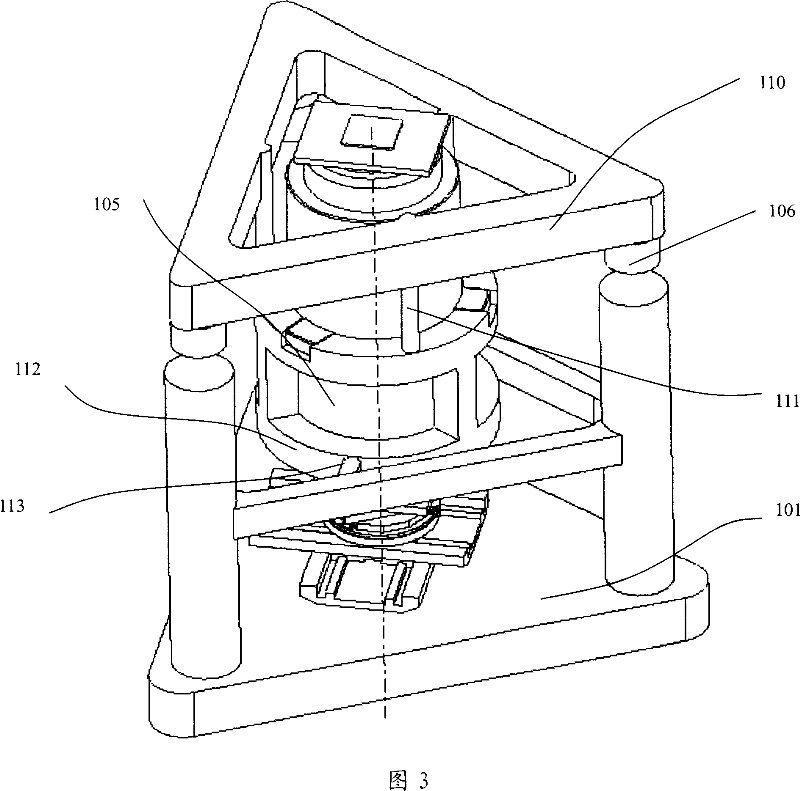

[0018] As shown in Figures 1, 2, and 3, the suspended support imaging system of the present invention includes an imaging system 105 and a supporting device, and also includes a state detection sensor 103 and an active execution device 113, and the state detection sensor 103 is fixedly arranged on the imaging system 105 Above; the active execution device 113 is arranged between the support frame 112 and the base frame 101 of the imaging system 105, which is connected to the state detection sensor 103 for receiving the signal obtained by the position state sensor and controlling and correcting the position of the imaging system 105; The supporting device is a suspension member 111, the imaging system 105 is suspended at the lower end of the suspension member 111, and the imaging system 105 is connected with the lower end of the suspension member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com