New preparation method for raising rate of packaging microspheres of naltrexone

A technology of naltrexone and encapsulation rate, which is applied in the field of formulations, can solve the problems such as the encapsulation rate is not reached, and achieve the effect of improving the encapsulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

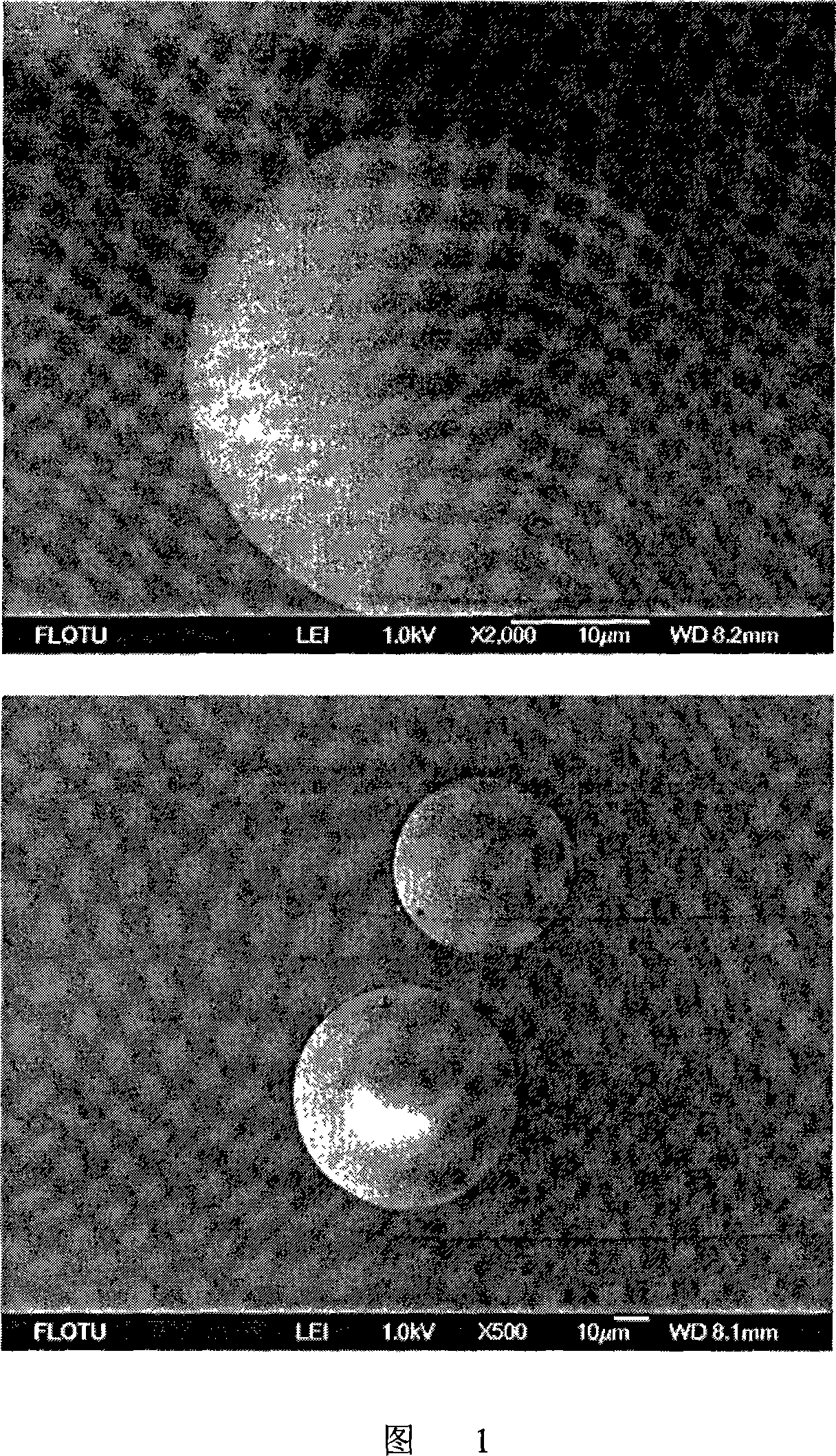

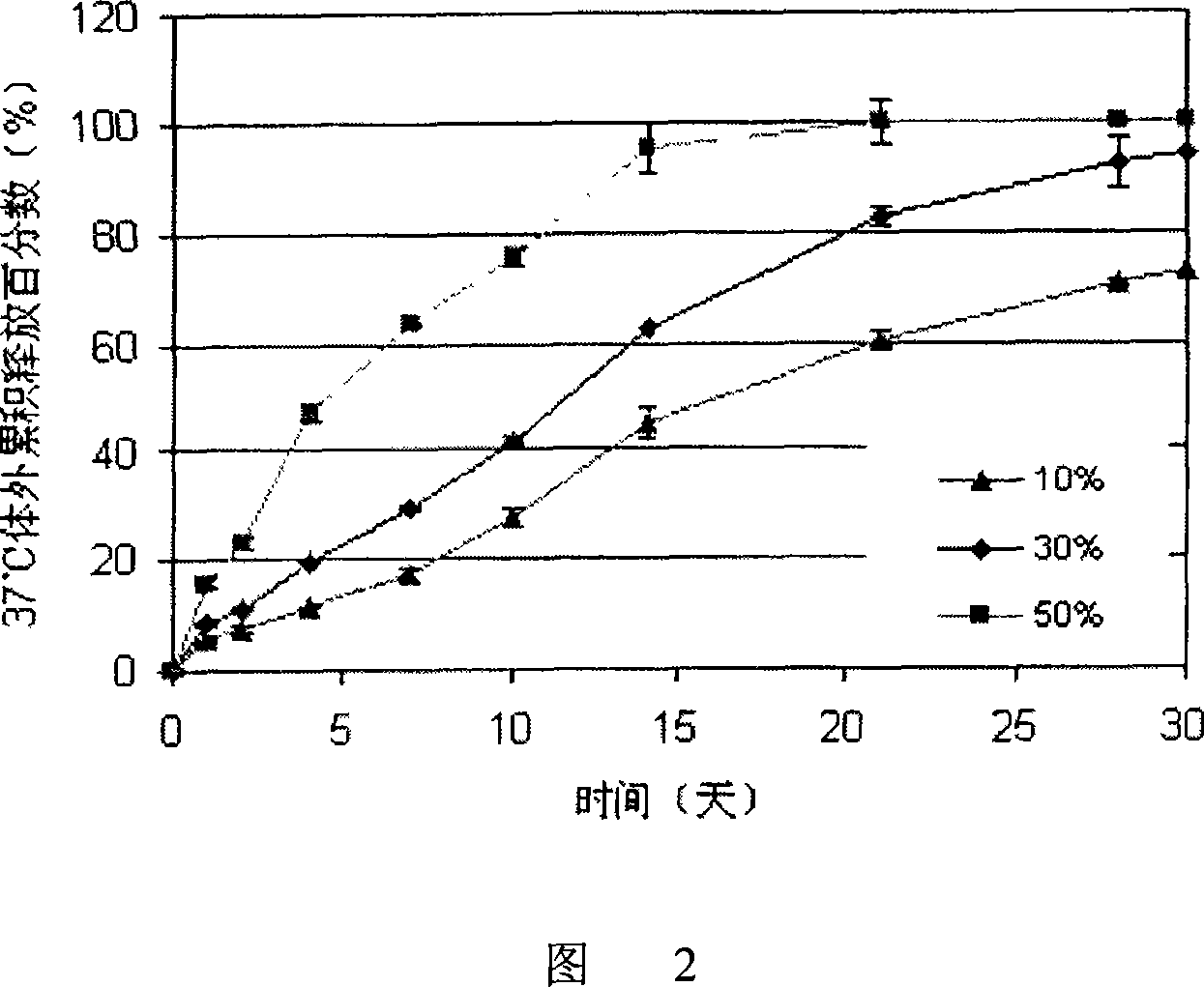

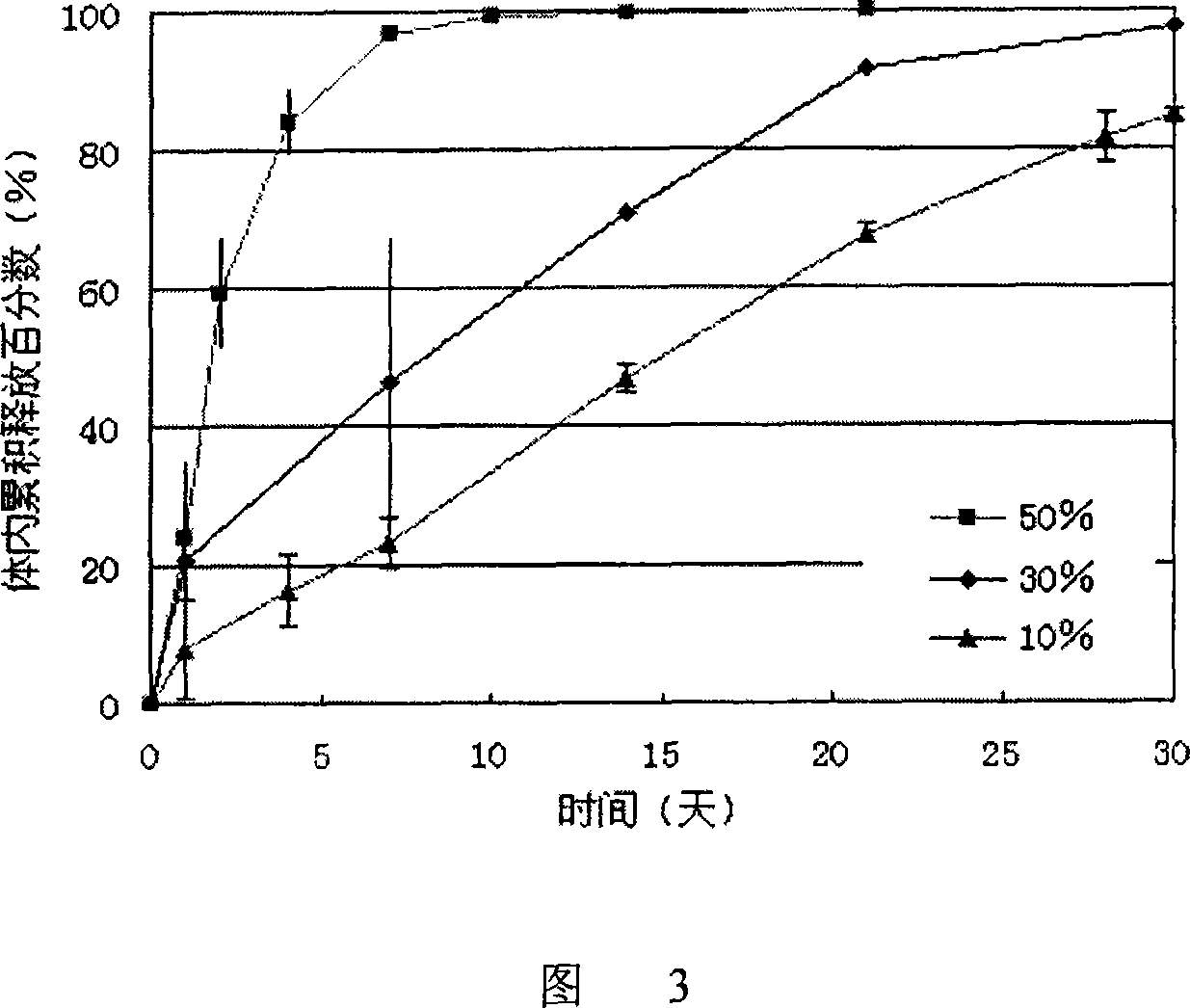

[0028] Accurately weigh a certain amount of polylactide-glycolide (poly(d, l-lactic-co-glycolic acid), PLGA, polymerization ratio 75:25, molecular weight 15000) and a certain amount of naltrexone free base, so that the theoretical loading The doses were 10%, 30% and 50% respectively (see Table 1), and 1.6ml of dichloromethane was added, vortexed and dissolved at room temperature to obtain a dispersed phase, so that the total solid concentration of the solution was 25%. In the 50ml beaker, add 10ml in the continuous phase (pH 9.0) that contains 0.2% polyvinyl alcohol, place on the magnetic stirrer, set the rotating speed 600rpm, disperse phase is added dropwise in the continuous phase, form O / W type emulsion, After 30 minutes, transfer to a beaker containing 90ml of continuous phase, stir at 300rpm for 5h, centrifuge to collect the obtained microspheres, wash with distilled water several times, then collect by centrifugation, freeze-dry to obtain the final product. The appearan...

Embodiment 2

[0031] Accurately weigh 280mg of polylactide-glycolide (polymerization ratio 75:25, molecular weight 15000) and 120mg of naltrexone free base, the theoretical drug loading is 30%, add 1.6ml of dichloromethane, vortex to dissolve at room temperature to obtain Disperse the phase so that the total solids concentration of the solution is 25%. Add different volumes (see Table 2) into the continuous phase (pH 9.0) containing 0.2% polyvinyl alcohol in a 50ml beaker, place it on a magnetic stirrer, set the rotating speed at 600rpm, and add the dispersed phase dropwise to the continuous phase to form O / W type emulsion, after 30min, transfer to the beaker that the remaining continuous phase (to make the continuous phase total volume 100mL) is housed, stir 5h with the rotating speed of 300rpm, centrifuge, collect the microspheres gained, wash with distilled water several times, and then Collect by centrifugation and freeze-dry. The appearance of the obtained microspheres is smooth and r...

Embodiment 3

[0034] Accurately weigh 280mg of polylactide-glycolide (polymerization ratio 75:25, molecular weight 15000) and 120mg of naltrexone free base, the theoretical drug loading is 30%, add 1.6ml of dichloromethane, vortex to dissolve at room temperature to obtain Disperse the phase so that the total solids concentration of the solution is 25%. In a 50ml beaker, add 10ml of different pH continuous phases containing 0.2% polyvinyl alcohol (see Table 3), place on a magnetic stirrer, set the speed at 600rpm, and add the dispersed phase dropwise to the continuous phase to form an O / W After 30 minutes, transfer to a beaker containing 90ml of continuous phase, stir at 300rpm for 5h, centrifuge to collect the obtained microspheres, wash with distilled water for several times, then collect by centrifugation, freeze-dry to obtain. The appearance of the obtained microspheres is smooth and round, and the measured encapsulation efficiency results are shown in Table 3.

[0035] polylac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| encapsulation rate | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com