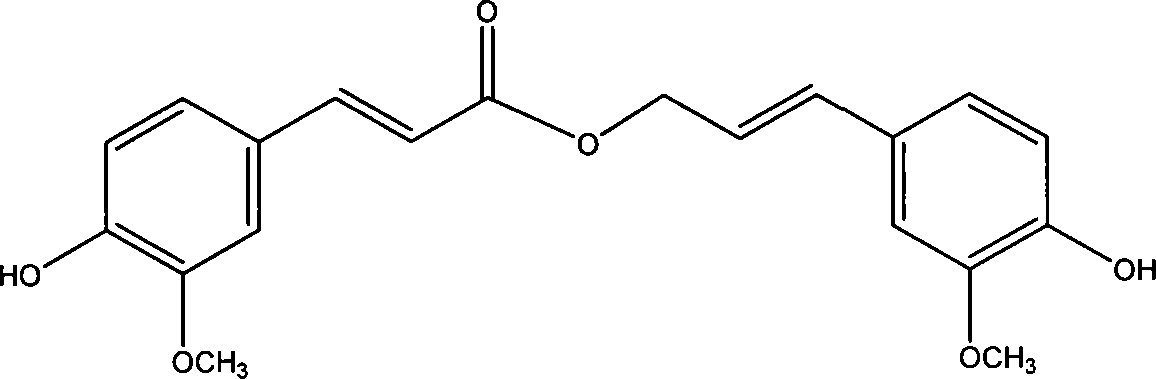

Method for preparing extractive of Chinese traditional medicine rich in coniferyl alcohol ferulic acid, and application in preparing medication, health products, or cosmetic

A technology of coniferyl ferulic acid and extract, which is applied in the field of preparation of Chinese medicine extracts, and can solve the problems of inconvenient industrial production and complex separation and purification methods of coniferyl ferulic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Chinese medicine angelica powder is extracted by carbon dioxide supercritical extraction (extraction pressure 25MPa, extraction temperature 40°C, extraction time 4h) or organic solvent (10 times the amount of traditional Chinese medicine), and then the organic solvent is evaporated to prepare essential oil.

[0038] Take 50g of the above-mentioned angelica oil, add 500ml n-octane (or n-hexane, or cyclohexane, or methylcyclohexane, or n-heptane), ultrasonically extract for 10min, pour out the supernatant, and add 500ml n-octane to the residue. octane, repeat the above extraction process for a total of 5 times, and dry the residue to obtain coniferyl ferulate concentrate.

[0039] The coniferyl ferulic acid enrichment is detected by HPLC, calculated according to the normalization method, at 318nm (coniferyl ferulic acid maximum absorption wavelength), the peak area percentage of coniferyl ferulic acid is 79.9% (40.5%~79.9%) ), the extraction rate was 79.3% (49.5%-87.6%). ...

Embodiment 2

[0041] Get the angelica oil 30g of carbon dioxide supercritical extraction, add 100ml n-hexane (or cyclohexane, or methylcyclohexane, or n-heptane, or n-octane), 100ml 95% ethanol (or methyl alcohol, or propanol, Or isopropanol, or n-butanol), 50ml water, static layering. After separation, 100 ml of n-hexane was added to the lower water-alcohol phase, and the above extraction operation was repeated for a total of 3 times. The final obtained water-alcoholic phase is recycled to dryness to obtain the coniferyl ferulate enriched product.

[0042] The coniferyl ferulic acid enrichment is detected by HPLC, calculated according to the normalization method, at 318nm, the coniferyl ferulic acid peak area percentage is 62.0% (62.0%-62.6%), and the extraction rate is 28.5% (28.5%) -63.4%). The enrichment of coniferyl ferulate has obvious anti-oxidation and anti-platelet aggregation effects.

Embodiment 3

[0044] Mix n-hexane, ethyl acetate, ethanol and water at a ratio of 1:1:1:1, let stand to separate layers, take the upper layer (organic layer) as the stationary phase, and the lower layer (alcoholic water) as the mobile phase, and carry out countercurrent chromatography. In the washing method, the stationary phase is injected into the high-efficiency countercurrent chromatograph at a flow rate of 5ml / min and 300rpm (the rotor is 240ml). After the rotor is filled with the stationary phase, the mobile phase is injected into the high-performance countercurrent chromatograph at a flow rate of 2ml / min and 1500rpm. Injection. Sampling method: Dissolve 1.5g angelica oil in 4ml mixed solvent (2ml mobile phase + 2ml stationary phase) and inject the sample, collect the chromatographic peak of coniferyl ferulate, detect by HPLC, calculate according to the normalization method, at 318nm , the peak area percentage of coniferyl ferulate was >93%, and the extraction rate was 71.2%. The enr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com