Industrialization preparing method for 3-propyl-ethylene oxide-2-carbonyl cyclopropanecarboxamide

A technology of carbonyl cyclopropanamide and ethylene oxide, which is applied in the field of industrial preparation of 3-propyl-oxirane-2-carbonyl cyclopropanamide, can solve the problems of difficult to meet market demand, difficult to purchase in large quantities, and production cost Advanced problems, to achieve the effect of convenient operation, mild reaction conditions, and easy-to-obtain materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

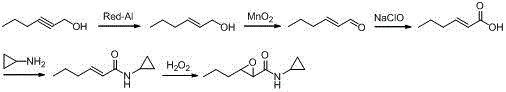

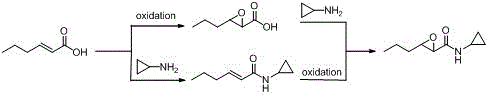

Method used

Image

Examples

Embodiment 1

[0035] An industrial preparation method of 3-propyl-oxirane-2-carbonyl cyclopropanamide, using malonic acid as a starting material, is realized through the following steps:

[0036] (1) Preparation of hexenoic acid

[0037] Put 38kg of pyridine and 2.39kg of diethylamine into the reaction kettle, open the circulating water, add 50kg of malonic acid, control the temperature below 40°C, add 35.34kg of n-butyraldehyde dropwise, control the temperature within 50°C during the period, after the dropwise addition Stir at room temperature for 15 hours, evaporate diethylamine under reduced pressure at 90°C, and lower the temperature. When the temperature drops to about 50°C, add 42kg of toluene and continue to cool down to below 20°C; add 53.2kg of 50% hydrochloric acid dropwise, during which the temperature is controlled at 25°C Within, until the pH value of the reaction solution reaches 1, evaporate to dryness under reduced pressure to obtain the crude product of hexenoic acid, cool ...

Embodiment 2

[0046] An industrial preparation method of 3-propyl-oxirane-2-carbonyl cyclopropanamide, using malonic acid as a starting material, is realized through the following steps:

[0047] (1) Preparation of hexenoic acid

[0048] Put 152kg of pyridine and 9.56kg of triethylamine into the reaction kettle, turn on the circulating water, add 200kg of malonic acid, control the temperature below 40°C, add 167.4kg of n-butyraldehyde dropwise, and control the temperature within 50°C during the period. Stir at room temperature for 15 hours, evaporate triethylamine under reduced pressure at 90°C, and lower the temperature. When the temperature drops to about 50°C, add 168kg of ethanol, continue to cool down to below 20°C, and add 212.8kg of 50% phosphoric acid dropwise. During this period, the temperature is controlled at 25 Within ℃, until the pH value of the reaction solution reaches about 3, evaporate to dryness under reduced pressure to obtain the crude hexenoic acid, cool down, and set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com