Technique for producing carbon black by using coke oven gas instead of fuel oil

A technology of coke oven gas and fuel oil, applied in the direction of fibrous fillers, etc., can solve the problems of poor quality grade of carbon black, poor process stability, and reduced service life of the combustion furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

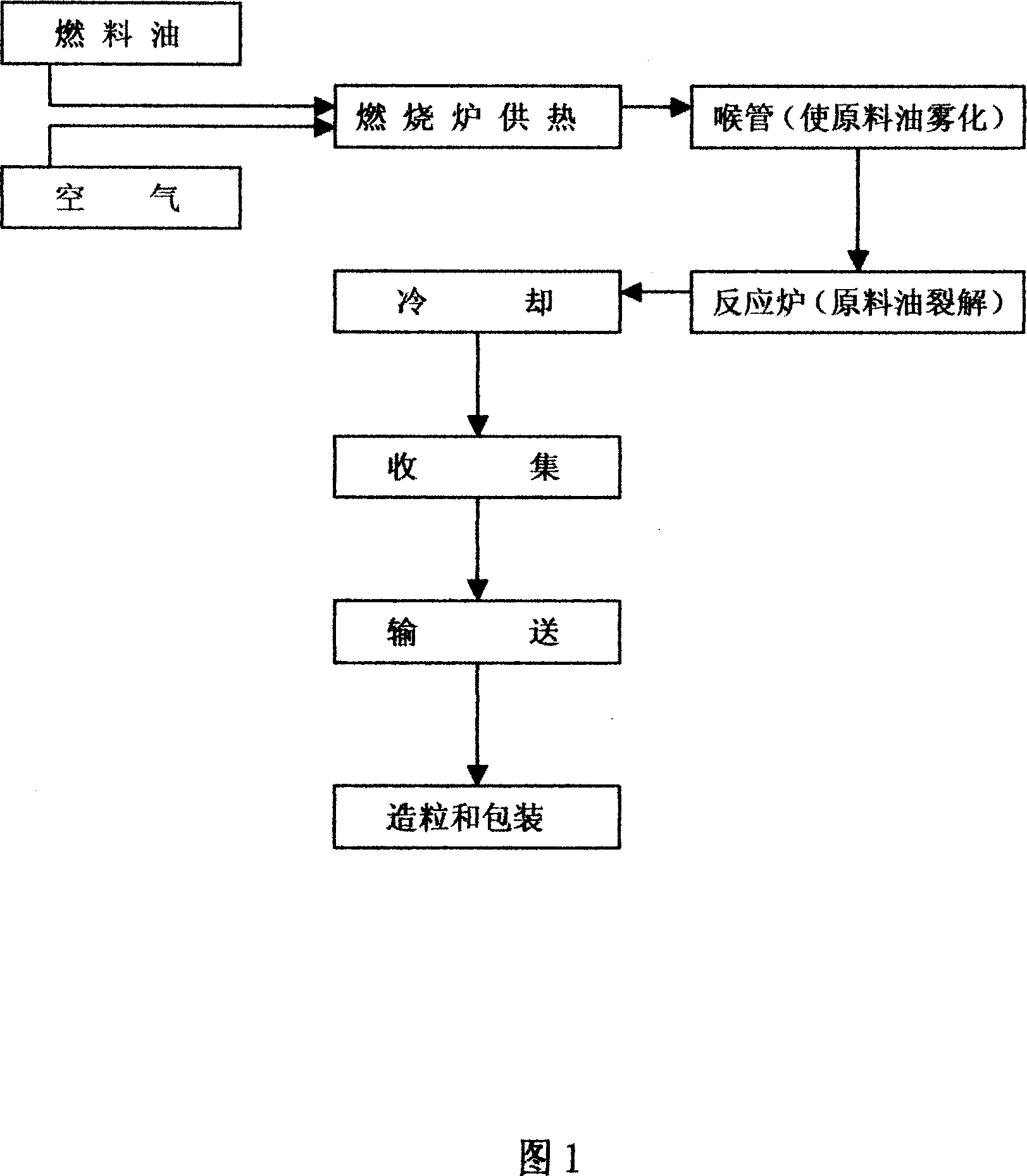

[0007] Figure 1 is a flow chart of the existing carbon black production process. Fuel oil and air are mixed in a certain proportion and enter the combustion furnace for combustion. The heat after combustion enters the throat pipe to atomize and vaporize the raw material oil added at the throat pipe. , After the pyrolysis reaction occurs in the reaction furnace, carbon black, combustion gas and pyrolysis gas are produced, and then cooled by the cooling device, collected, transported, and finally granulated and packaged.

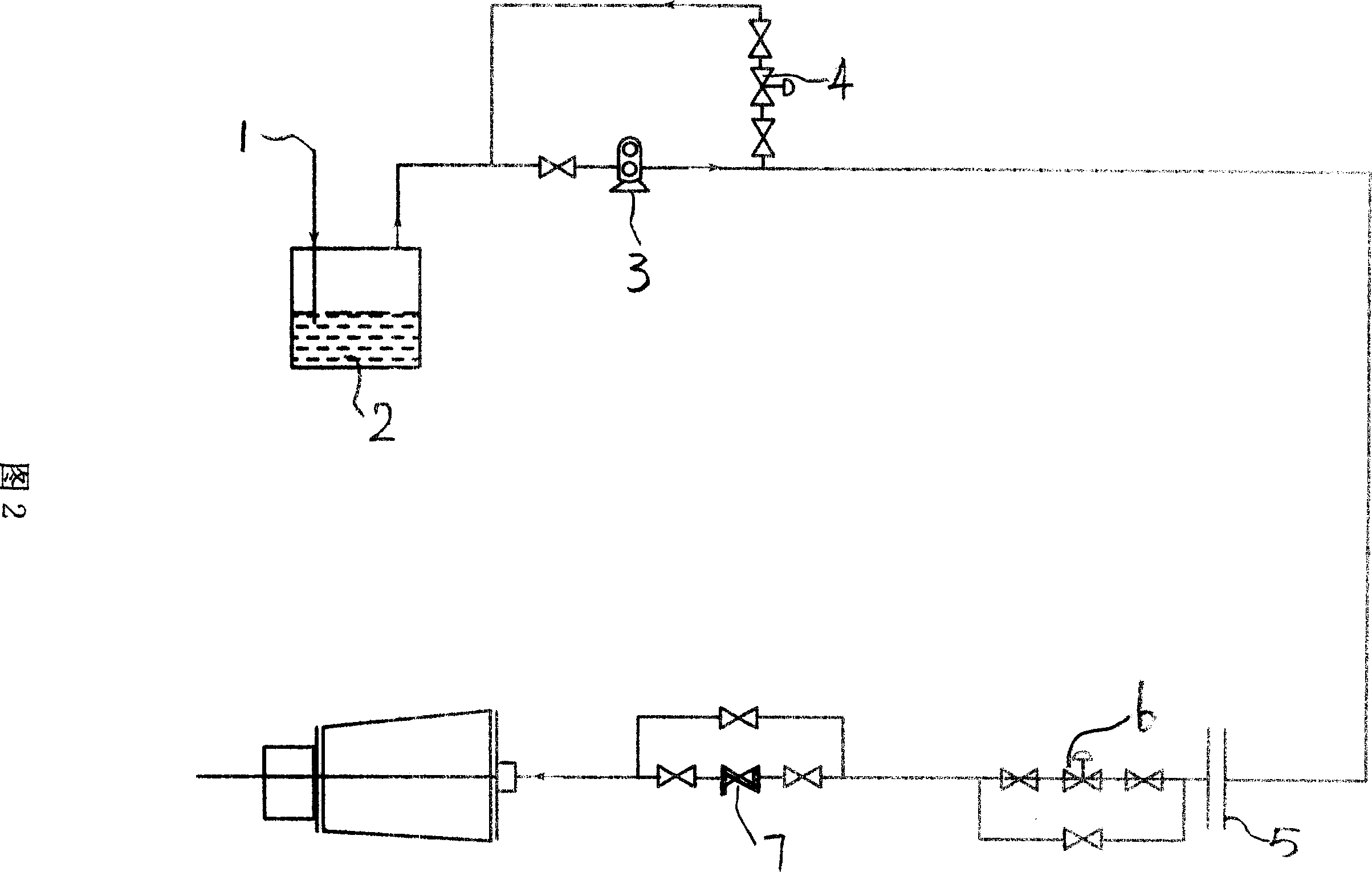

[0008] Fig. 2 is the coke oven gas treatment process flow chart, the technology that coke oven gas replaces fuel oil to produce carbon black, comprises the previous stage process step and the back stage process step, is to replace fuel oil with coke oven gas in the previous stage process step; The process steps in the previous stage are as follows: first, the collected coke oven gas 1 is treated by the water seal device 2, the pressure is adjusted by the gas bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com