Honeycomb heater with infrared radiation function used on gas burner

A honeycomb heating element and infrared radiation technology, which is applied in household heating, household appliances, household heating, etc., can solve the problems of flame fluctuating with the airflow and instability, and achieve uniform and powerful flames, stable combustion, increased strength and The effect of wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

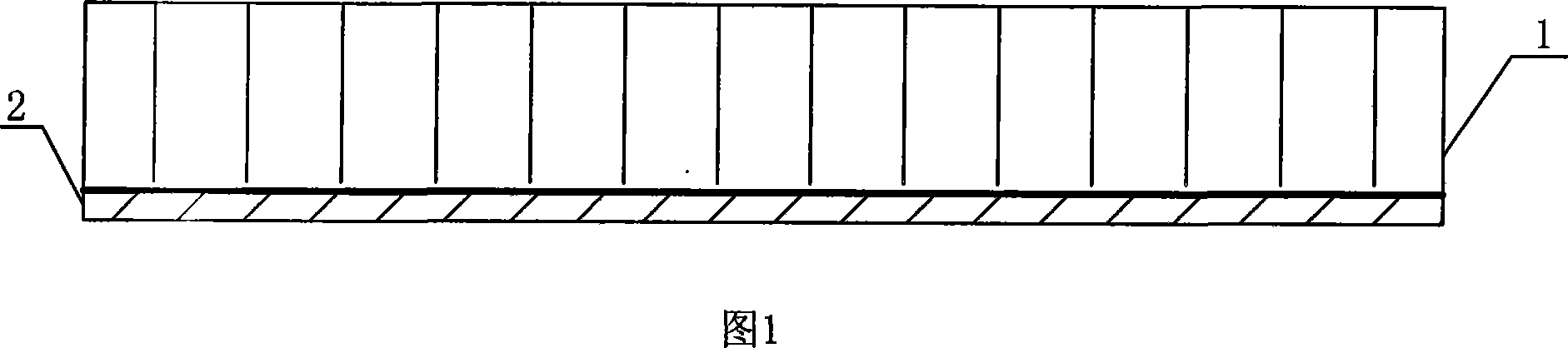

[0012] As shown in accompanying drawing 1, it is a preferred embodiment of the present invention. The upper layer of the honeycomb heating element is a surface honeycomb heating layer 1 made of high-temperature-resistant and corrosion-resistant nickel-chromium-aluminum alloy, and the lower layer is made of high-temperature-resistant and corrosion-resistant A mesh body or fiber body 2 made of flexible metal iron-chromium-aluminum materials, wherein the upper layer and the lower layer are connected together by direct lamination or lamination welding. The mesh body or fiber body 2 is flat.

Embodiment 2

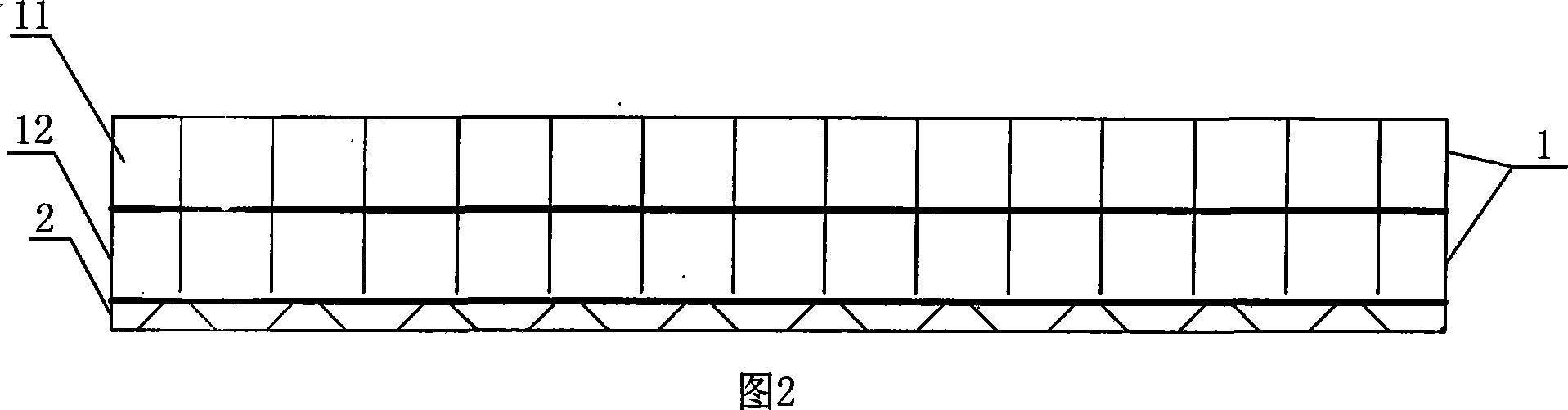

[0014] As shown in Figure 2, the difference from the first embodiment is that the surface honeycomb heating layer 1 is composed of a nickel-chromium-aluminum alloy honeycomb component 11 and a relatively low-cost iron-chromium-aluminum alloy honeycomb component 12 stacked on top of each other or The composite honeycomb heating layer formed by lamination and welding (because the flame burns mainly on the upper surface, it has no effect on the overall performance, but the cost is reduced). The mesh body or fiber body 2 is corrugated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com