Liquid crystal display devices and polarizing plate sets used therein

A technology of liquid crystal display devices and polarizers, applied in polarizing elements, optics, instruments, etc., can solve the problems of brightness leakage, large color shift, etc., and achieve the effects of reducing the number of used parts, eliminating edge irregularities, and reducing the number of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

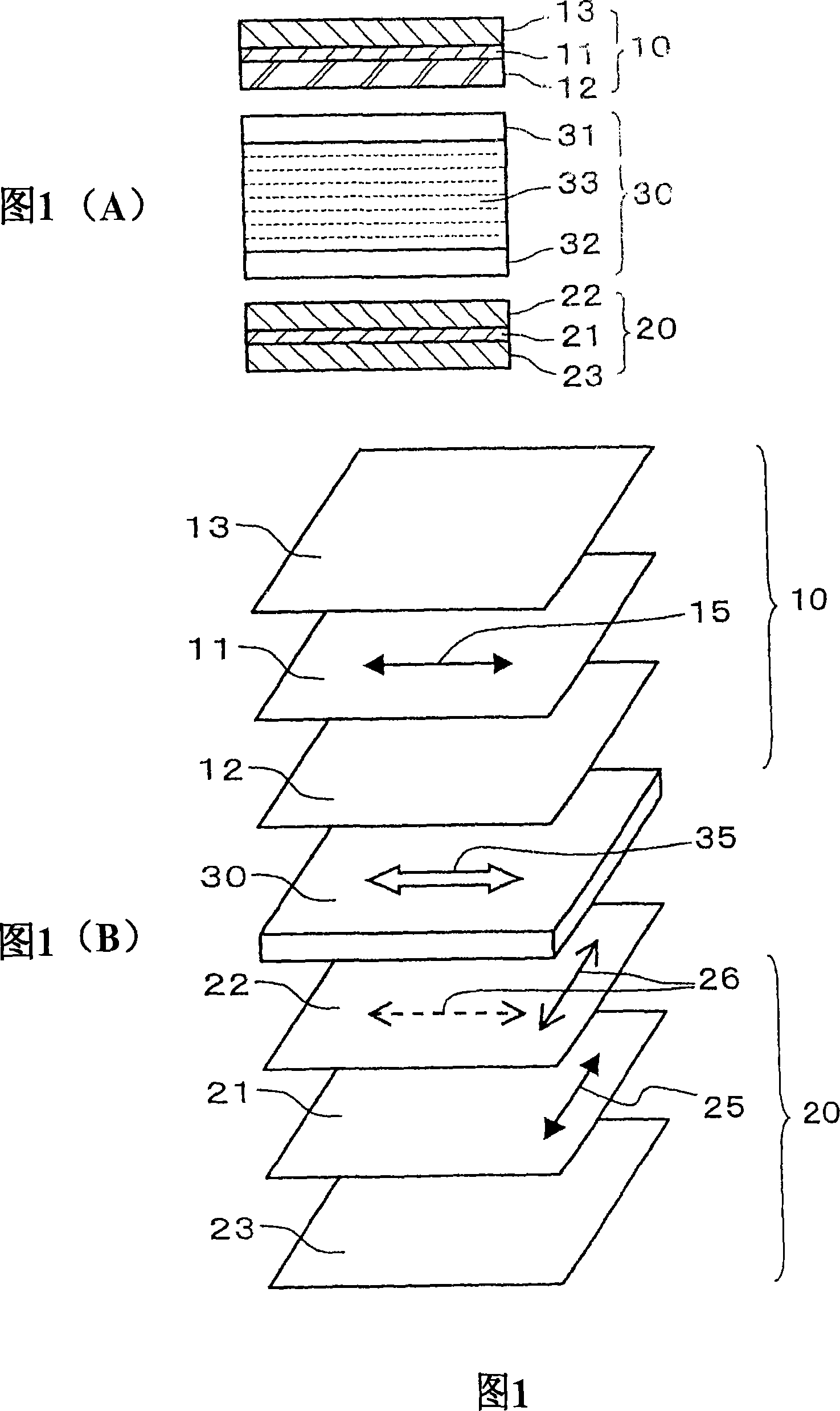

Method used

Image

Examples

Embodiment 1

[0091] (a) The first polarizer

[0092] A linear polarizing plate was prepared, which was one side of a polarizer in which iodine was adsorbed and oriented on a polyvinyl alcohol film, and a non-oriented transparent protective film (manufactured by Fuji Film Co., Ltd. Z-TAC”, R 0 =2nm, Rth=0nm), on the other side, a transparent protective film made of cellulose triacetate was attached. Use it as the first polarizer.

[0093] (b) Second polarizer

[0094] The norbornanyl resin film was oriented in the thickness direction according to the method described in the above-mentioned patent document 6, and R 0 =280 nm, three-dimensionally oriented transparent resin film of Nz=0.4. When the wavelength dispersion of the retardation of the obtained transparent resin film is measured, it is

[0095] R(450nm) / R(550nm)=1.00,

[0096] R(650nm) / R(550nm)=1.00.

[0097] The measurement wavelengths are indicated in parentheses.

[0098] The above-mentioned three-dimensionally oriented tr...

Embodiment 2

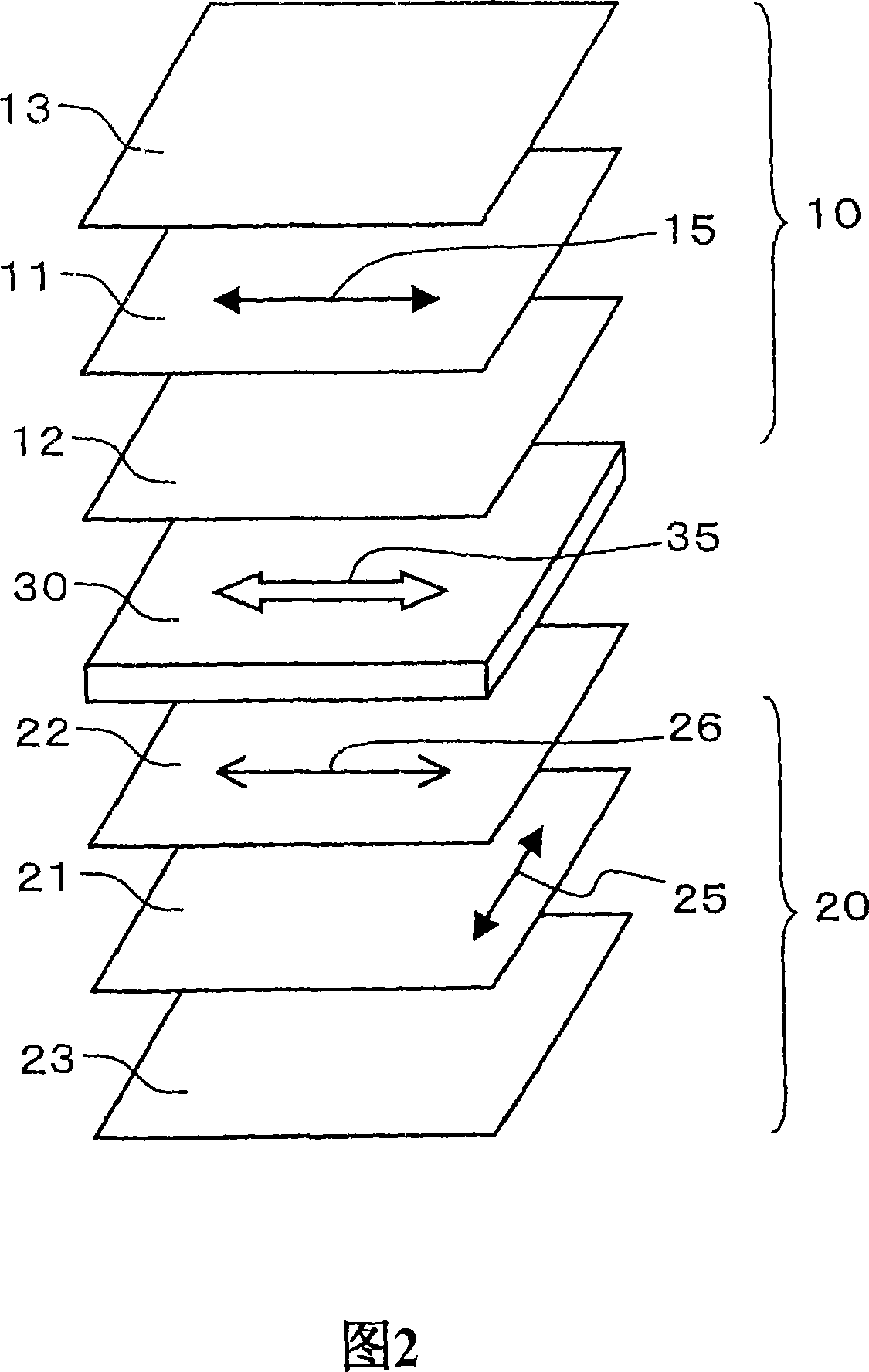

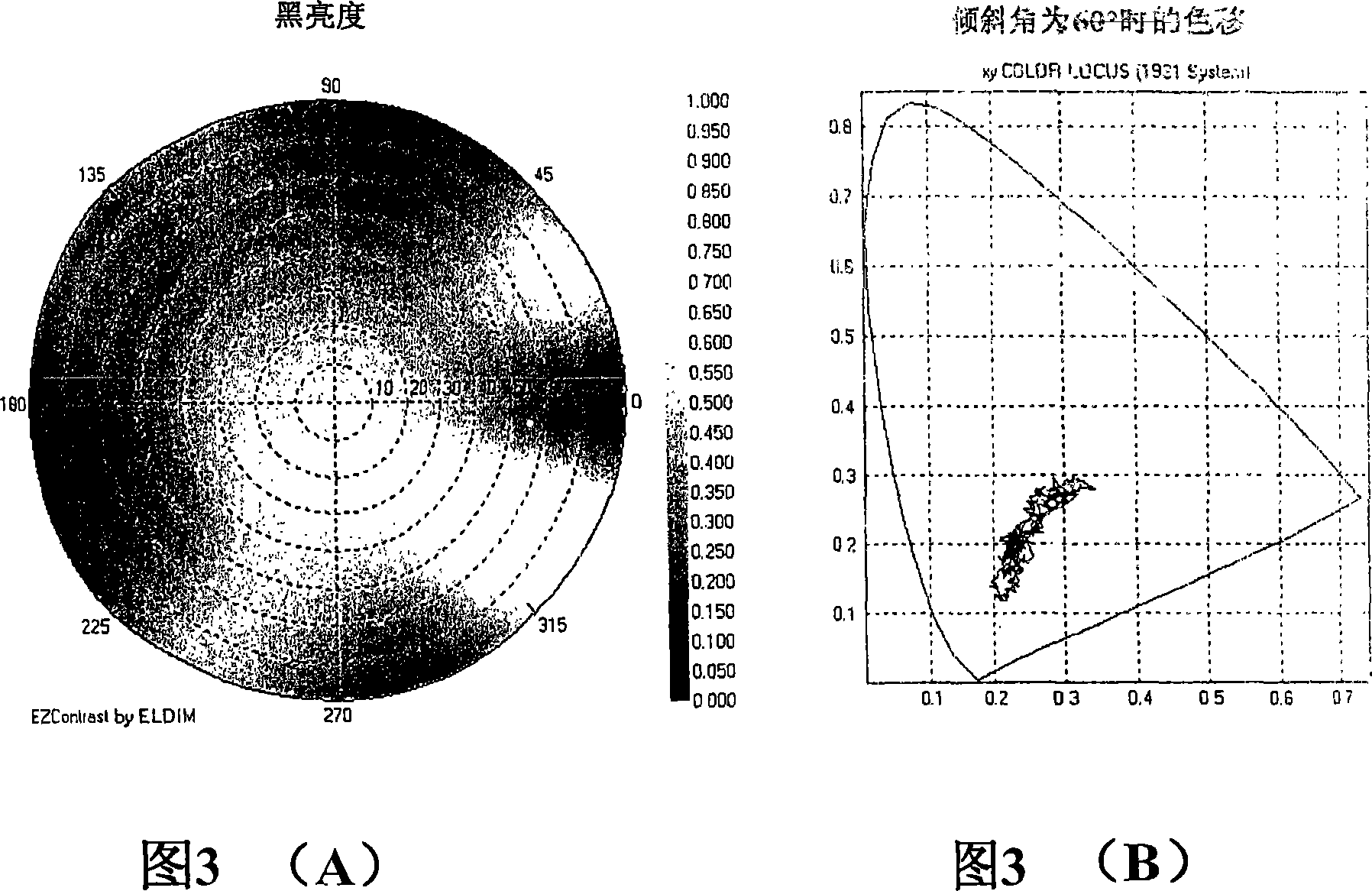

[0105] A liquid crystal display device was produced and evaluated in the same manner as in Example 1, except that the retardation axis of the three-dimensionally oriented resin film constituting the second polarizing plate was parallel to the absorption axis of the polyvinyl alcohol iodine polarizer. The layer configuration and axis relationship of the liquid crystal display device manufactured here are shown in a schematic perspective view in FIG. 4 . In the arrangement shown in this figure, the retardation axis 26 of the transparent protective layer 22 on the side of the liquid crystal cell constituting the second polarizing plate 20 is fixed in a direction parallel to the absorption axis 25 of the polarizer 21. Only this point is different from that of FIG. 1(B )different. The evaluation results of this example are shown in FIG. 5 in the same manner as in FIG. 3 . However, FIG. 5(A) shows a place where the inclination angle is close to 90° from the normal direction. From ...

Embodiment 3

[0107] (a) The first polarizer

[0108] A linear polarizing plate was prepared as a first polarizing plate in the same manner as in (a) of Example 1.

[0109] (b) Second polarizer

[0110] The norbornanyl resin film was oriented in the thickness direction according to the method described in the above-mentioned patent document 6, and R 0 =250nm, three-dimensionally oriented transparent resin film of Nz=0.4. The wavelength dispersion of the retardation of the obtained transparent resin film was as good as that obtained in (b) of Example 1. The measurement wavelengths are indicated in parentheses.

[0111] Using a polyvinyl alcohol-based adhesive, the above three-dimensionally oriented transparent resin film is attached to one side of a polarizer in which the polyvinyl alcohol film is adsorbed and oriented with iodine, and a transparent protective film containing cellulose triacetate is attached to the other side. , to manufacture linear polarizers. At this time, the in-pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com