Ozonidate prepn. plant

A technology for manufacturing equipment and ozone water, which is applied in the directions of ozone preparation, oxidized water/sewage treatment, transportation and packaging, etc., which can solve the problems of expensive ozone water production equipment, complicated manufacturing process of silent mixer, and high manufacturing cost, and achieve low price Solubility, reduction of maintenance frequency, effect of operating cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

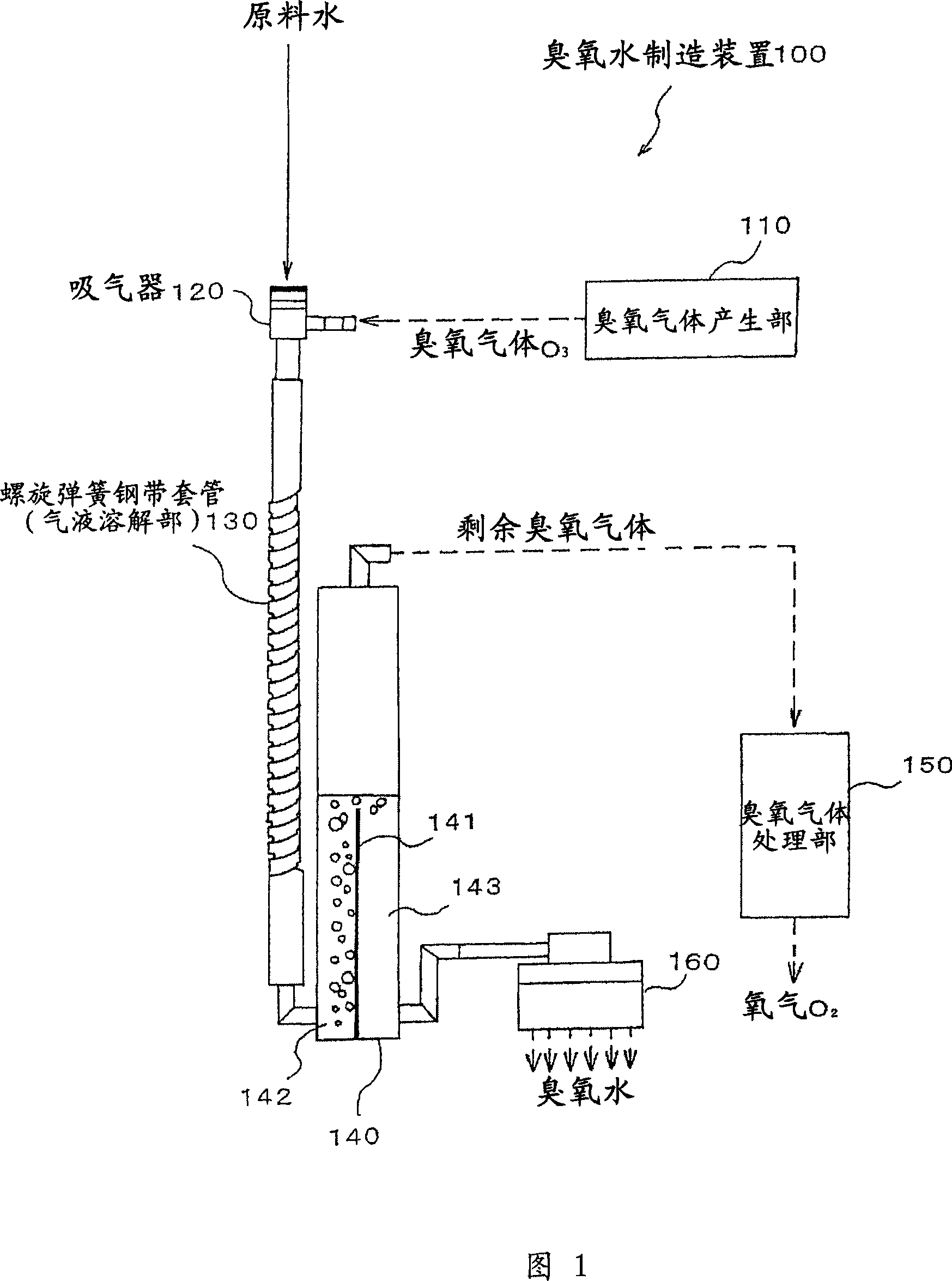

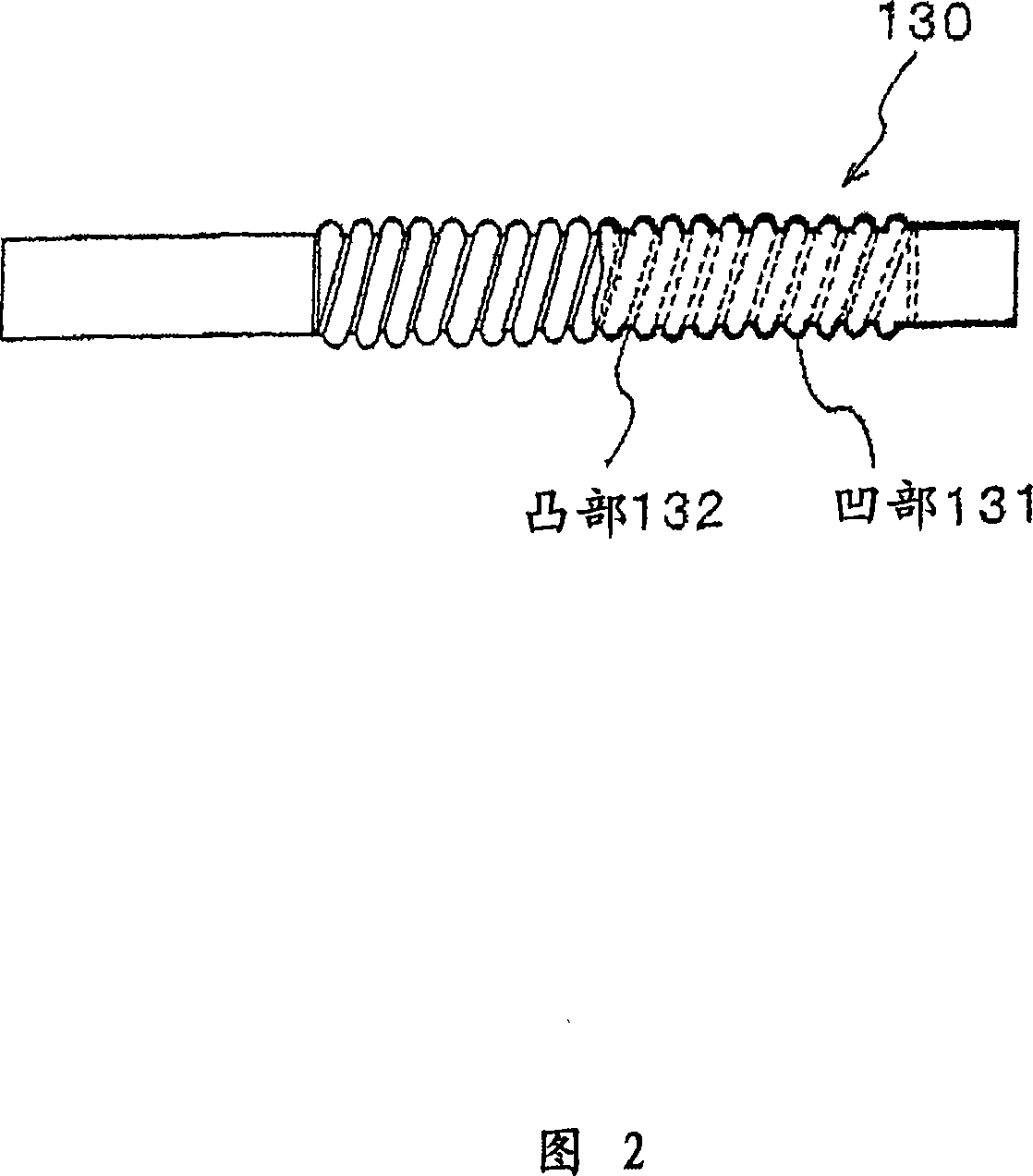

[0021] The ozone water manufacturing apparatus related to this invention has: an ozone gas generating part; an aspirator; a gas-liquid dissolving part; and a gas-liquid separating part.

[0022] An existing ozone gas generator can be used for the ozone gas generating part, for example, a gas containing oxygen can be passed between a pair of electrodes arranged in parallel flat plates or coaxial cylinders to generate ozone by discharging. Ozone gas generator of silent discharge type of gas, and a pair of electrodes sandwiched between electrolyte membranes are placed in water, and DC voltage is applied between the two electrodes to generate electrolysis of water. At this time, ozone is generated together with oxygen on the side where oxygen is generated. Electrolytic ozone gas generator, etc.

[0023] The aspirator is used to bring the raw material water into contact with the ozone gas generated by the ozone gas generating unit. That is, the aspirator is connected to the source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com