Motor coil expansion method and full servo digital control motor coil expander

A technology of numerically controlled motors and forming machines, which is applied in the fields of motor coil forming and full-servo CNC motor coil forming machines. Stretch deformation, precise and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

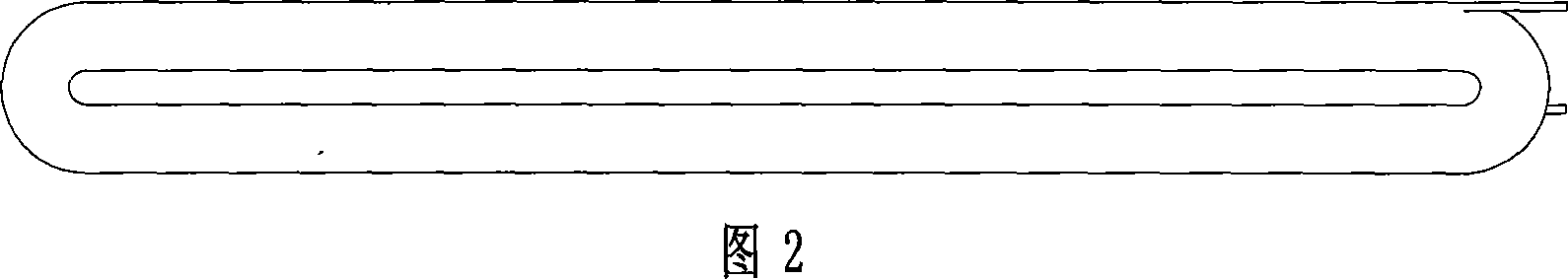

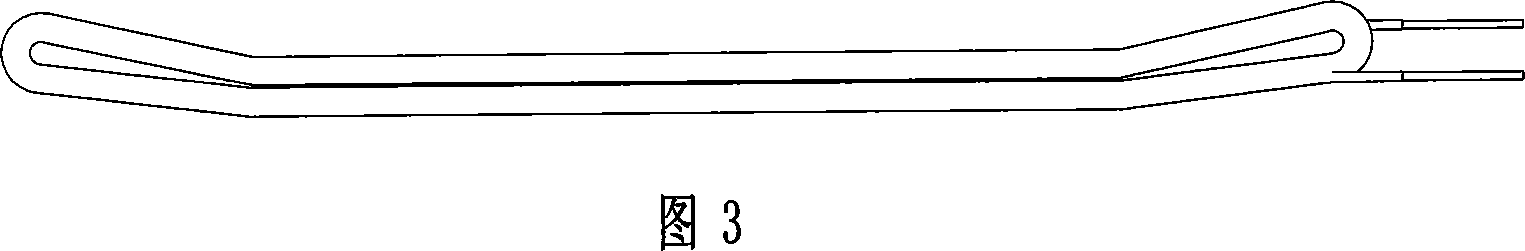

[0041] Adopt the method and equipment of the present invention to process the planar shuttle-shaped coils as shown in Figures 1 and 2, to obtain stretched in the XZ plane and raised ends in the XY plane as shown in Figures 3, 4 and 5 1. The outer stator forming coil that is twisted in the ZY plane, its processing process includes coil clamping, coil automatic expansion, and the coil expansion step includes stretching the coil to be expanded in a straight line and lifting the coil end High and coil straight edge twisting and nose twisting actions, arcs at each bend and end involute forming actions. Coil clamping is to clamp the shuttle-shaped coil to be expanded by 4 linear part clamping mechanisms and 2 nose end clamping mechanisms respectively, so that the length direction is in the XY plane and the axis direction is in the XZ plane. , the clamping point of the shuttle-shaped coil to be expanded is used as the process parameter positioning point of the coil expansion process....

Embodiment 2

[0055] The method and equipment of the present invention are used to process the shuttle-shaped coils shown in Figures 1 and 2 to obtain the inner stator coils shown in Figures 6, 7 and 8. The inner end is lifted in the opposite direction to the outer stator, and the straight edge and nose end are twisted in the ZY plane. The equipment action steps in the processing process are similar to those in Example 1, except that the lifting direction and twisting direction of the end are different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com