Friction welding machine closed loop control device

A technology of closed-loop control and friction welding machine, which is applied in the direction of electrical program control, program control in sequence/logic controller, manufacturing tools, etc. It can solve the problems of inability to perform real-time closed-loop control, reduce the number of valves used, and high probability of failure, etc. problem, achieve the effect of low hardware cost, reduce the number of use, and reduce the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

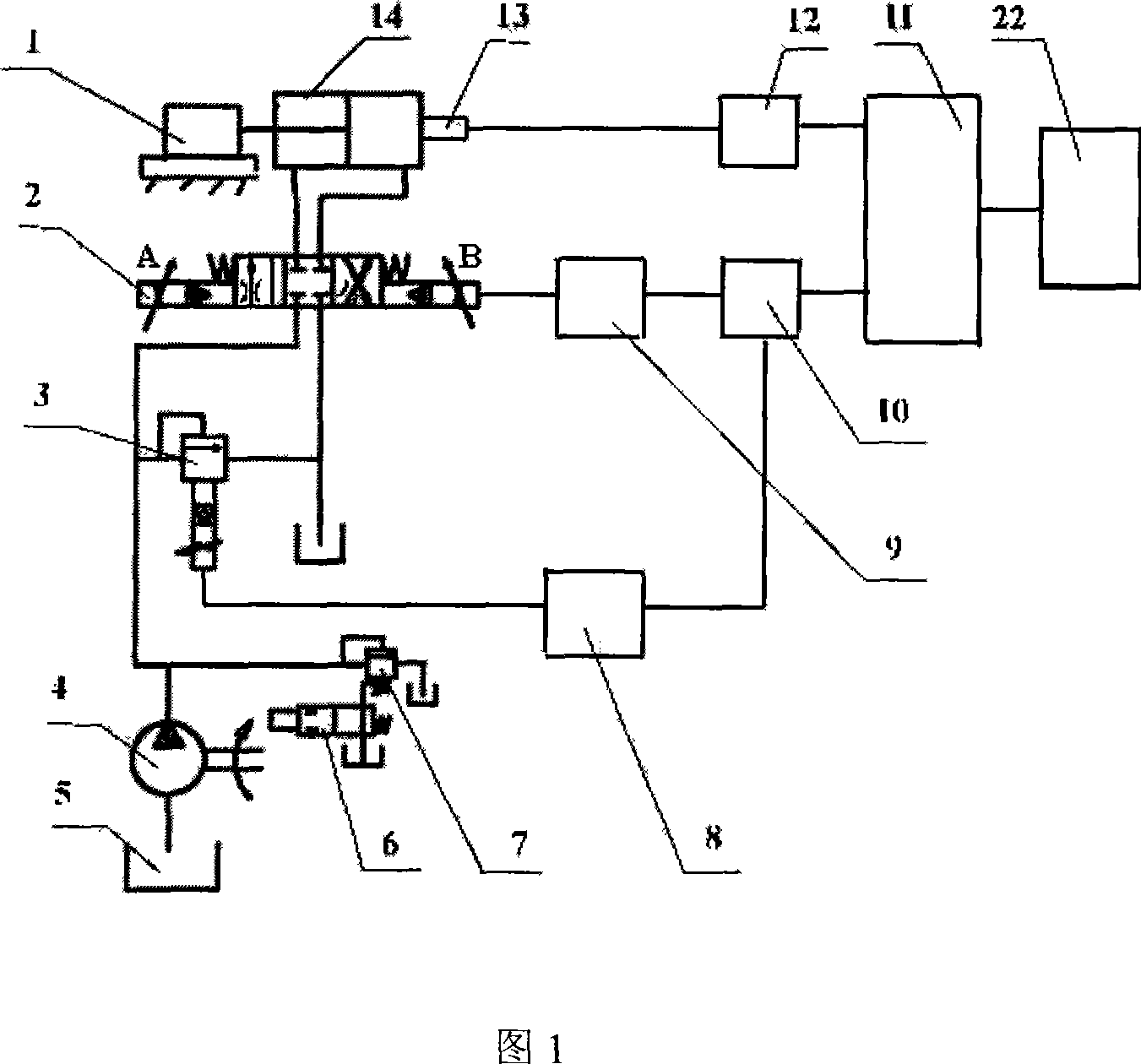

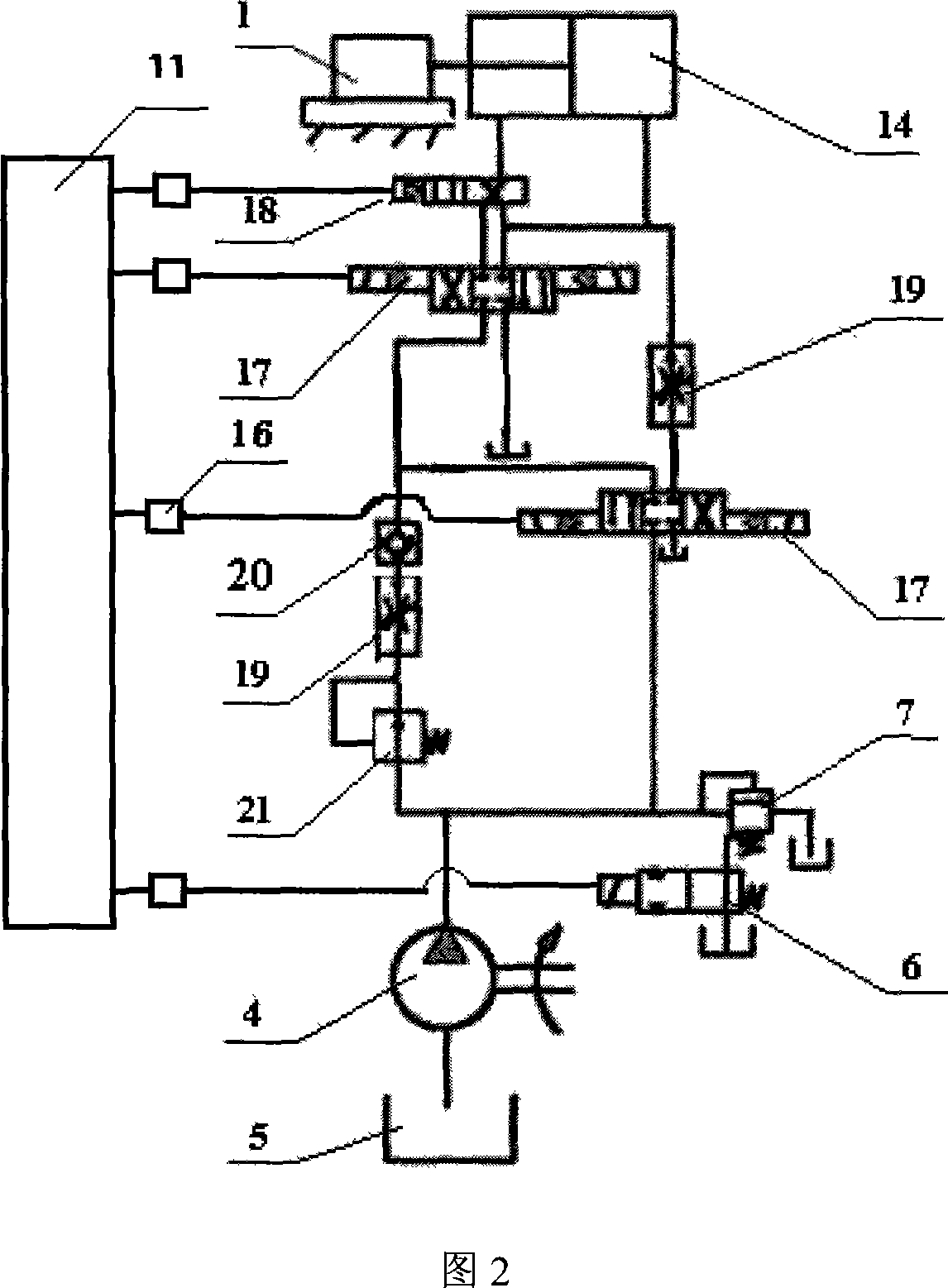

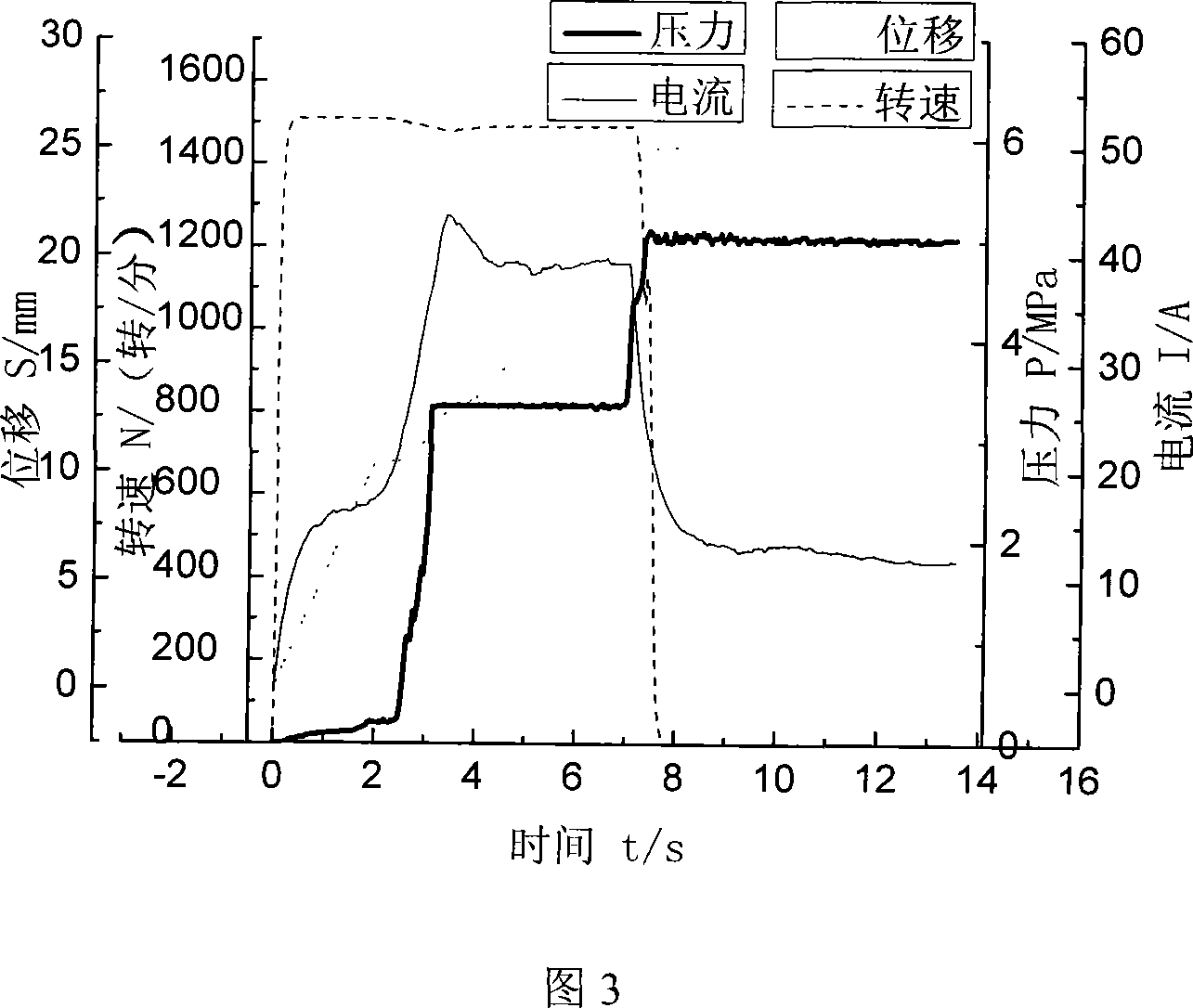

[0012] Referring to Fig. 1, the pressure value of the oil cylinder 14 of the drag slide 1 is converted into an analog signal of current or voltage by the pressure sensor 13, converted into a digital signal by the AD module 12 and sent to the PLC controller 11 for comparison with the set value. The set value is transmitted to the PLC controller 11 by the man-machine interface module 22 . The PLC controller 11 performs error calculation, and then converts the output digital value into a voltage value through the DA module 10 to control the output current of the A power amplifier board 8, and the output current of the A power amplifier board 8 adjusts the proportional solenoid on the electro-hydraulic proportional overflow valve 3 The electromagnetic force of the iron is used to control the overflow pressure of the proportional overflow valve 3 to realize the pressure control of the axial force cylinder 14. Simultaneously, the PLC controller 11 accepts the direction and speed ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com