High-intensity waterproof heat preservation aerating calcium sulfate composite panels production line

A thermal insulation and composite wallboard technology, which is applied in thermal insulation, ceramic molding workshops, building materials, etc., can solve the problems of many heat exchange links, large waste of energy, long production cycle, etc., and achieve simple process and small heat loss , the effect of fewer heat exchange links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

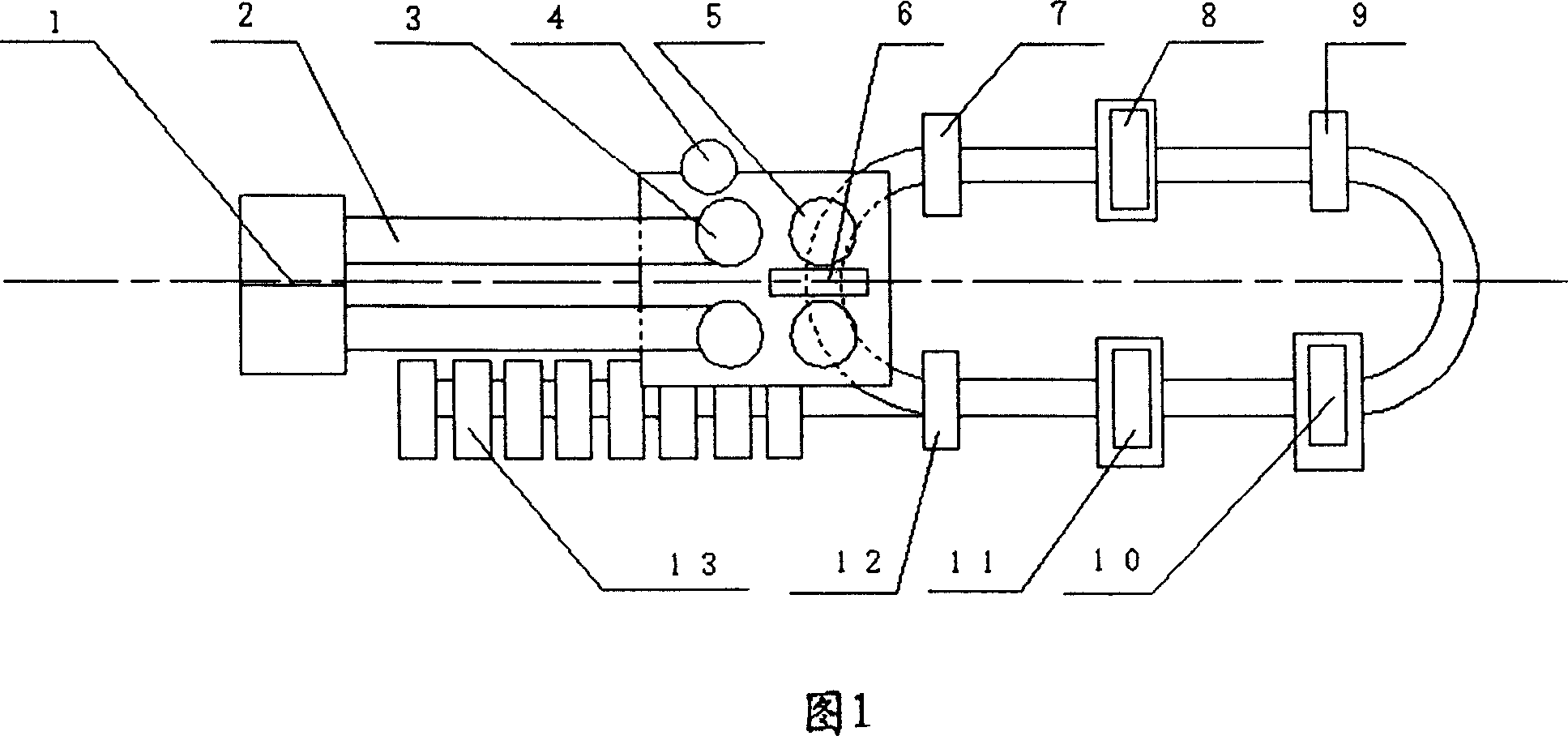

[0021] Referring to accompanying drawing 1, the production line of high-strength water-resistant thermal insulation aerated gypsum composite wallboard of this embodiment of the present invention, its batching mechanism 1 adopts the GY L-I double-barrel batching machine produced by Changsha Guiyi Building Materials Technology Co., Ltd., and the two barrels are batched simultaneously Its stirring mechanism 3 is provided with two, adopts Changsha Guiyi Building Material Technology Co., Ltd. to produce GYJ-I type mixer, this machine can stir simultaneously and automatically pours the material in the pouring bucket of casting mechanism 5; Casting mechanism 5 adopts GY Z-I Type casting machine with material storage barrel, the casting method of this machine is quantitative casting, and two casting mechanisms 5 are set; The mold machine presses the gypsum wallboard; the mold opening mechanism 9 adopts the GYK-I type mold opening machine; the demoulding mechanism 10 adopts a commercial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com