Tunnel radio laser laying out apparatus

A laser and tunnel technology, which is applied in tunnels, measuring devices, instruments, etc., can solve the problems of scanning range and distance limitation, inconvenient processing of curved tunnels, and occupation of tunnel traffic space, etc. The effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

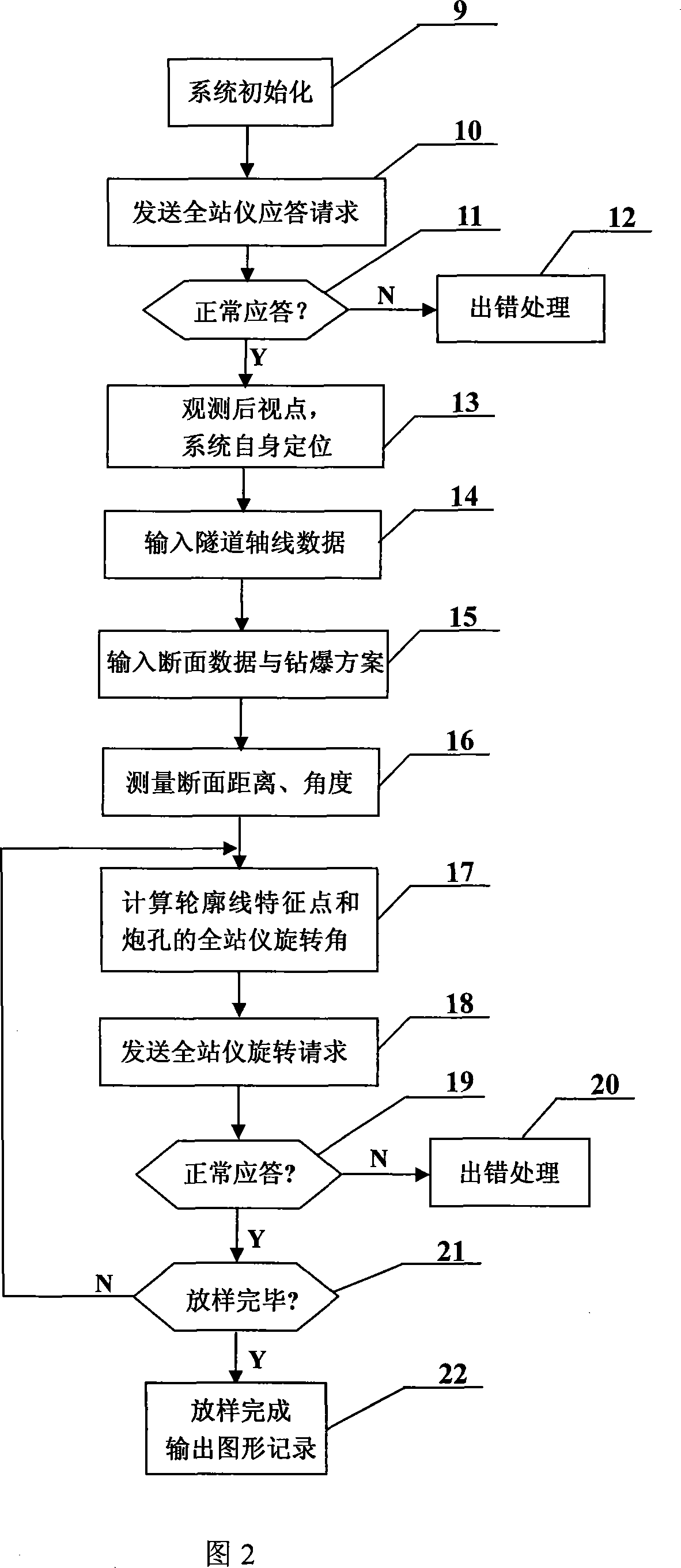

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

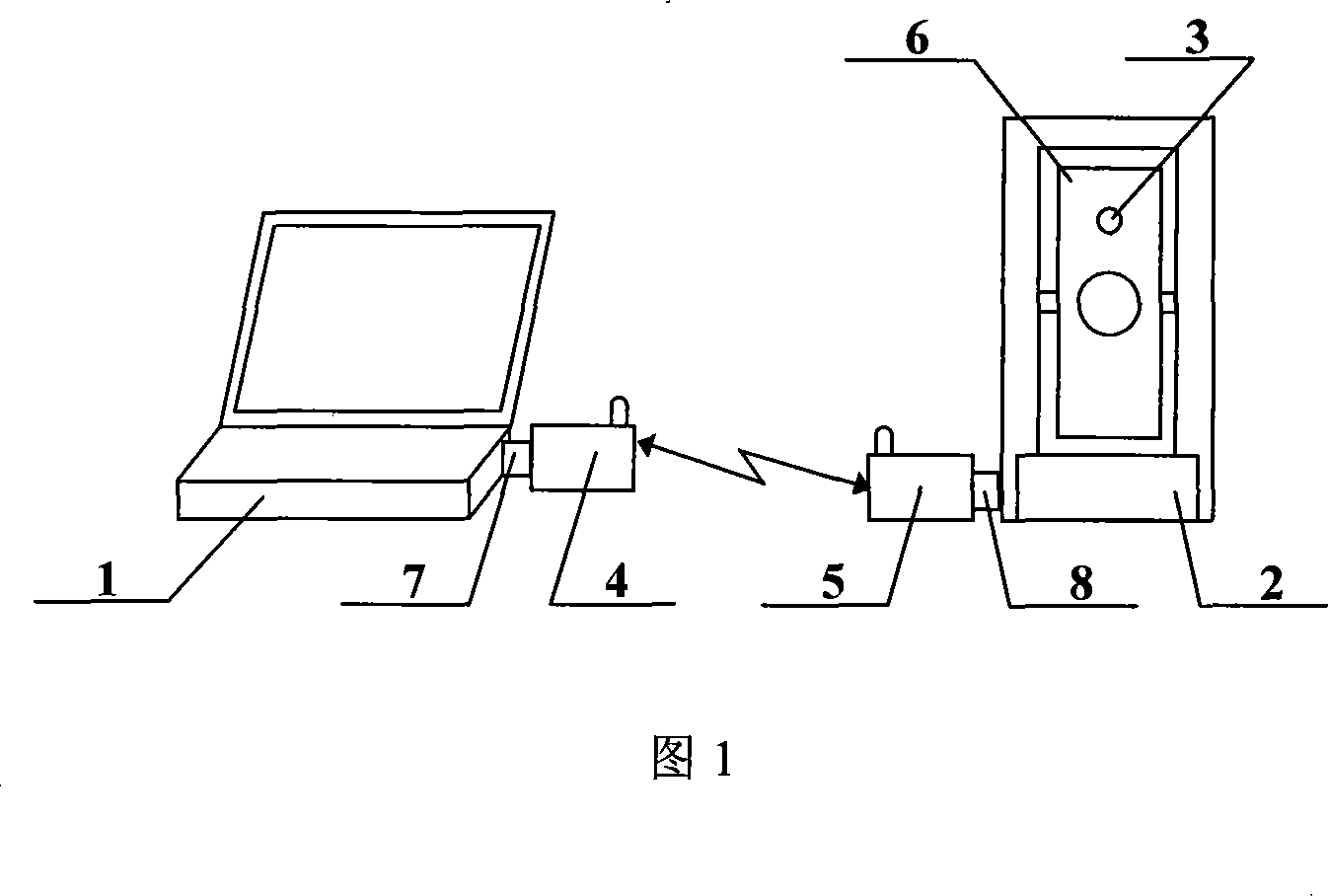

[0017] As shown in Figure 1, the system consists of a computer 1, a total station 2, a semiconductor laser 3 and wireless communicators 4 and 5. The computer 1 is equipped with control software, the computer 1 and the wireless communicator 4 are connected through the serial port 7, the total station 2 and the wireless communicator 5 are connected through the serial port 8, and the wireless communicators 4 and 5 are supporting bidirectional transmission communicators, The control signal of the computer 1 and the data signal of the total station 2 are decoded and transmitted through the wireless communicators 4 and 5 . In the specific implementation, the computer adopts a portable computer or desktop computer with a serial port; the total station adopts a servo-type electronic total station, and the optional models include Topcon 800 series, spectral FOCUS 10 series, Tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com