Large-scale producing method for non-crystal carbon nano tube

A technology of nanotubes and amorphous carbon, which is applied in the field of preparation of amorphous carbon nanotubes, can solve the problems of complex post-processing, complex equipment, and low yield, and achieve simple and easy methods, low energy consumption, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1. Preparation of amorphous carbon nanotubes

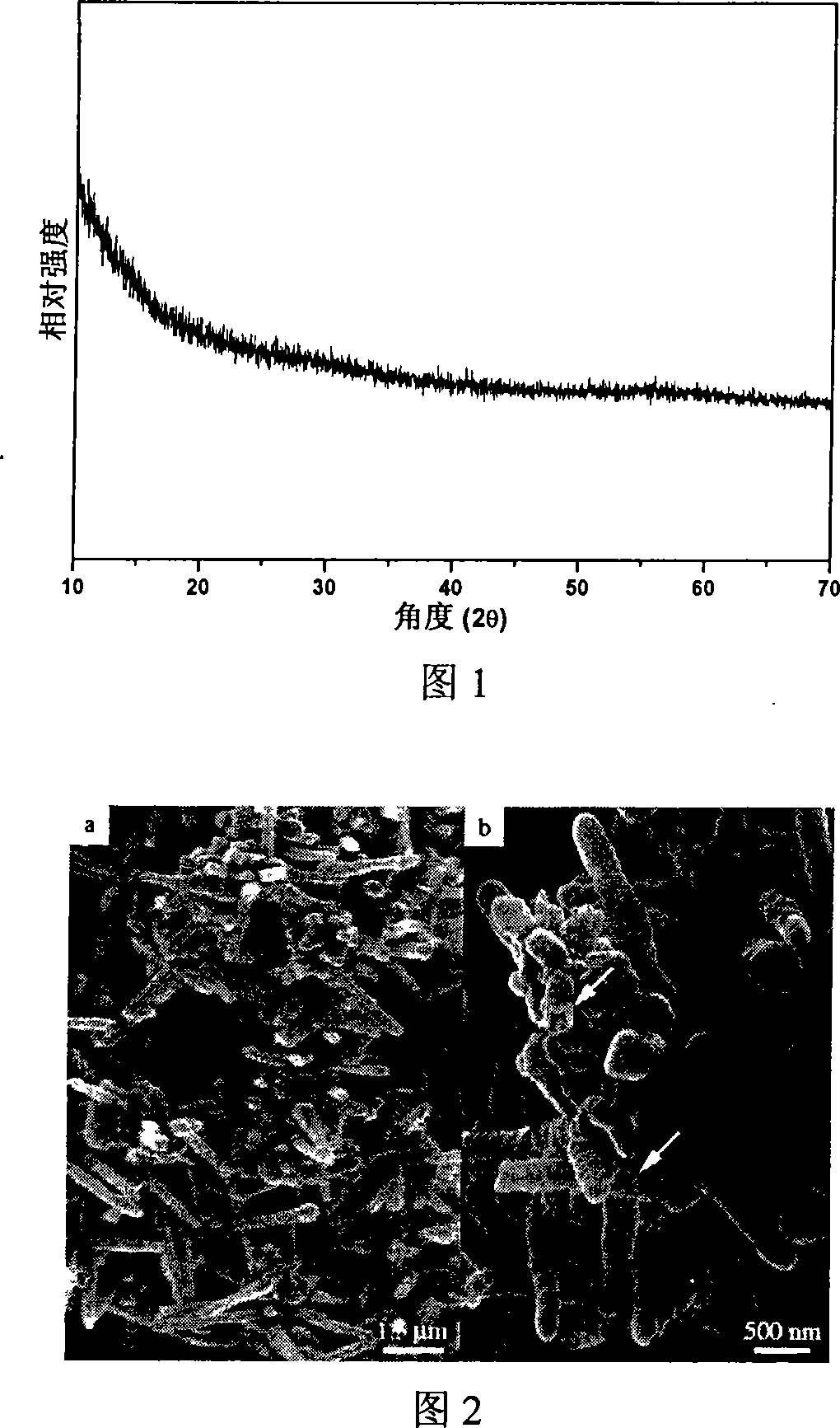

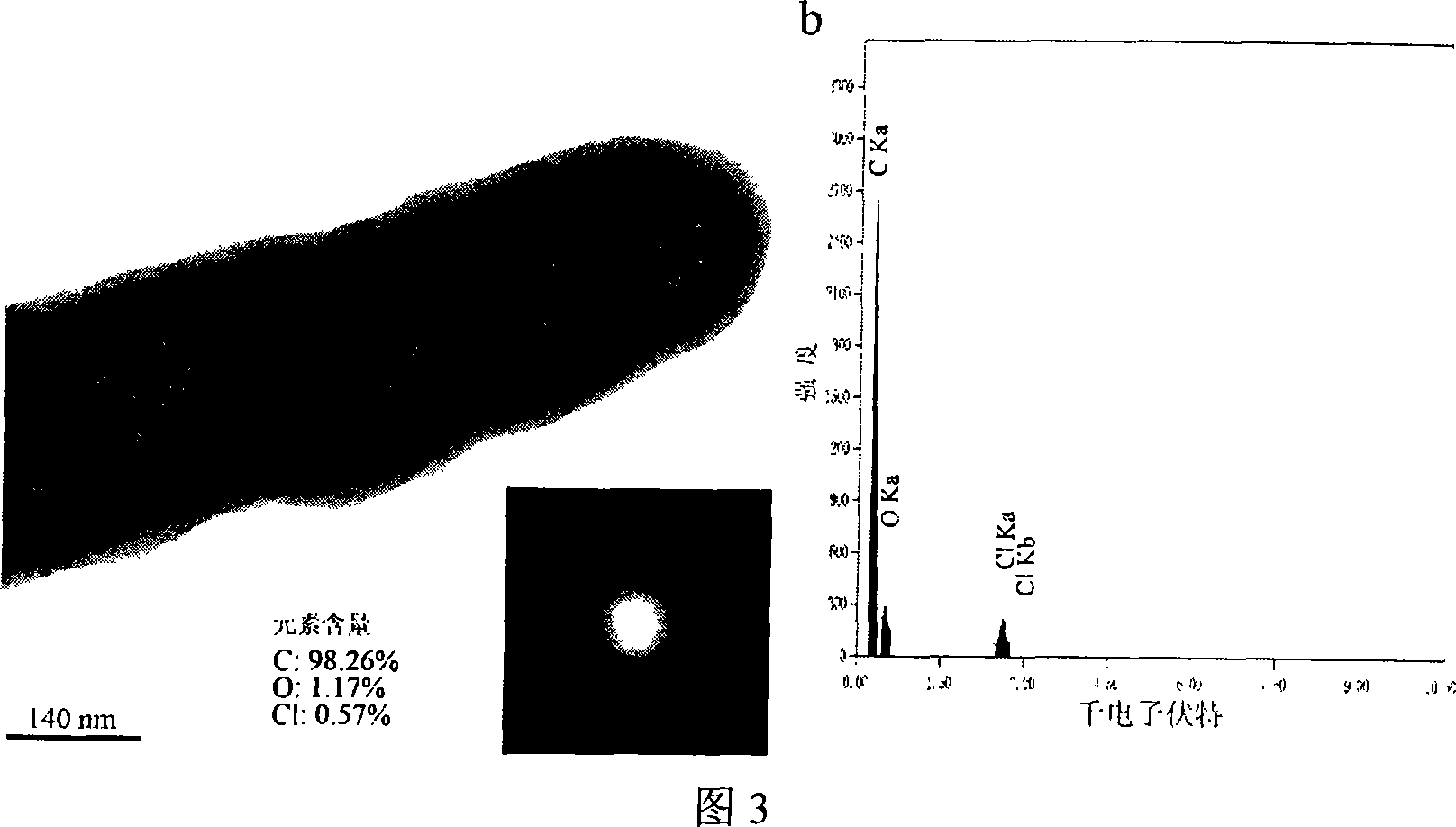

[0016] A method for preparing amorphous carbon nanotubes, which is to dissolve 2mmol ferrocene in 50ml carbon tetrachloride and stir evenly, move it into a stainless steel reaction kettle with a polytetrafluoroethylene substrate, and then heat up to 180°C for constant temperature reaction for 12 Hour. After the reaction, the filtered black product was washed three times with distilled water and ethanol in sequence, and finally dried in vacuum at 80° C. for 10 hours to obtain 0.8 g of amorphous carbon nanotubes. The product is measured by powder X-ray diffraction (XRD), and the result (see accompanying drawing 1) shows that there is no obvious diffraction peak, and it is a completely amorphous product. No heterogeneous peaks were found, indicating that the purity of the product is relatively high. Through SEM analysis (see Figure 2), it is observed that the amorphous carbon nanotube of the present invention has ...

Embodiment 2

[0017] Embodiment 2. Preparation of amorphous carbon nanotubes

[0018] Dissolve 2mmol of ferrocene in 50ml of carbon tetrachloride and stir evenly, move it into a polytetrafluoroethylene-lined stainless steel reaction kettle, then raise the temperature to 180°C for constant temperature reaction for 18 hours, and the other preparation conditions are the same as in Example 1. Likewise 0.8 g of a product of similar size and form was obtained.

Embodiment 3

[0019] Embodiment 3. Preparation of amorphous carbon nanotubes

[0020] Dissolve 2mmol of ferrocene in 50ml of carbon tetrachloride and stir evenly, move it into a polytetrafluoroethylene-lined stainless steel reaction kettle, then raise the temperature to 160°C and react at a constant temperature for 24 hours. The other preparation conditions are the same as in Example 1. Likewise 0.6 g of a product of similar size and form was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com