Self-resetting super-elastic shape memory alloy damper

A memory alloy and memory alloy wire technology, which is applied to building components, shockproof and other directions, can solve the problems of large residual deformation, weak energy dissipation capacity, long and narrow hysteresis curve, etc., to reduce residual deformation, low maintenance cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

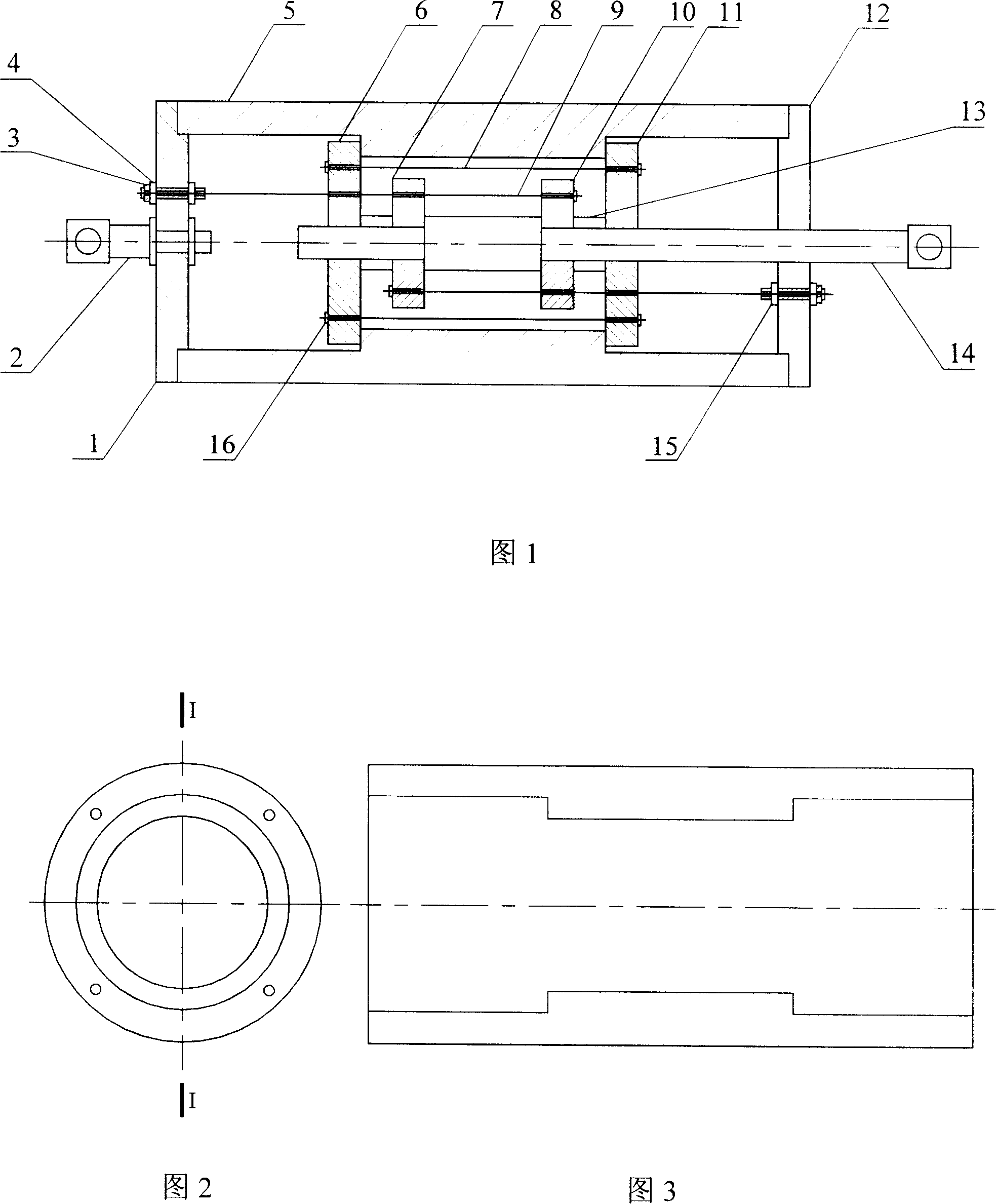

[0019] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

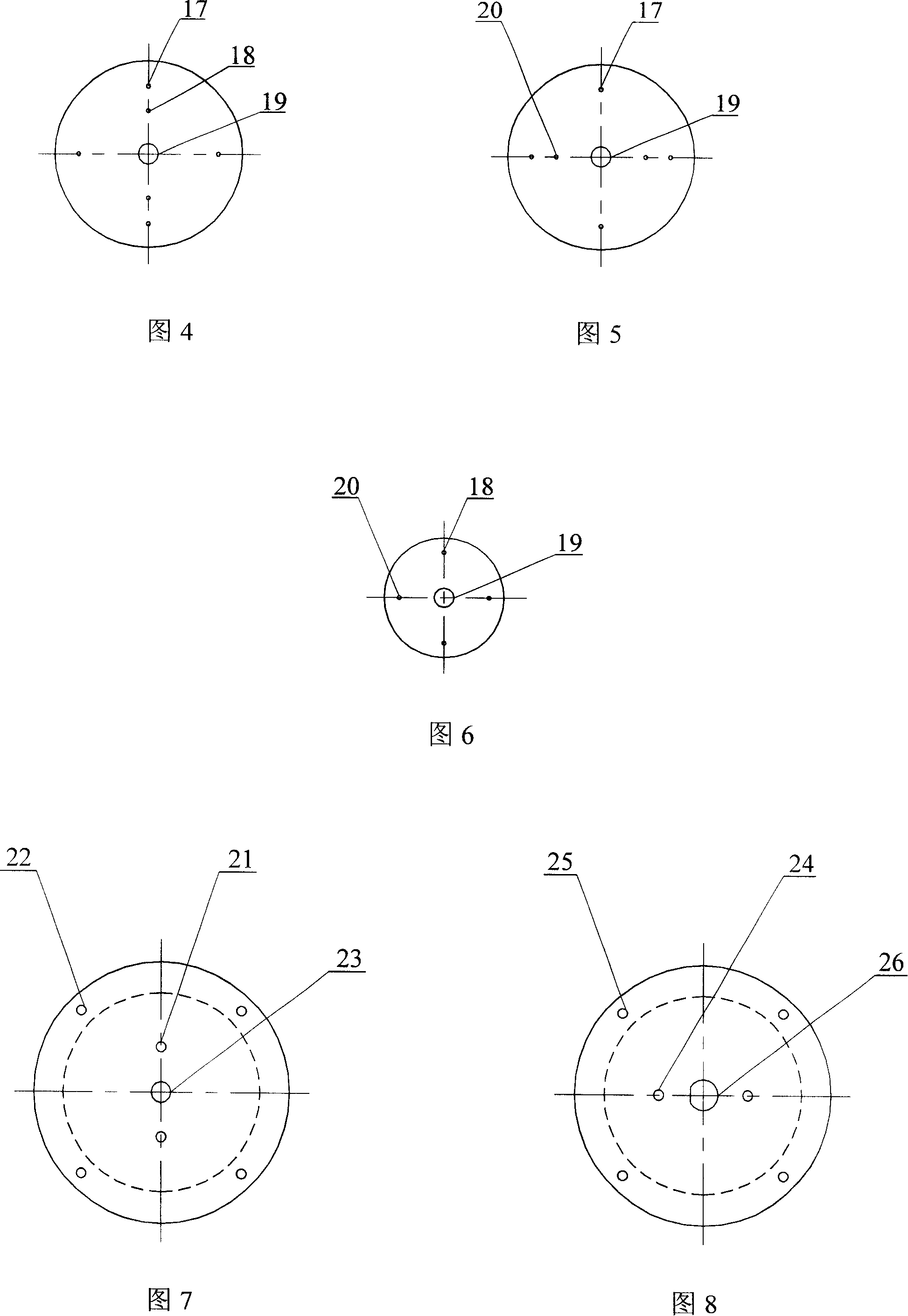

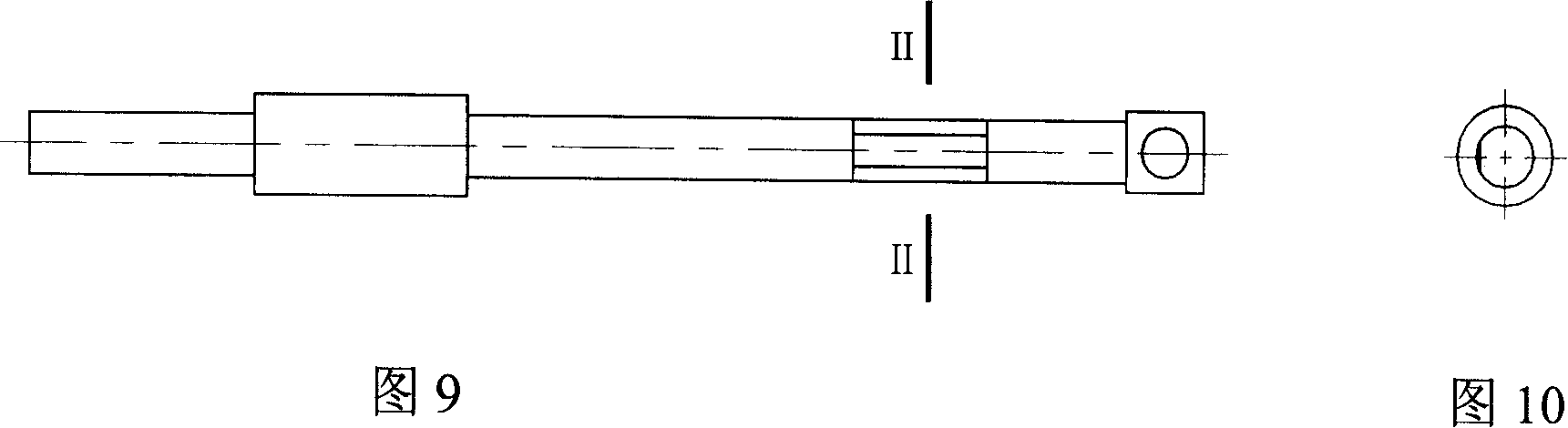

[0020] In Fig. 1, the center line and the lower part illustrate the central axisymmetric structure of the damper. The tie rod 14 is coaxial with the cylinder barrel 5 . Four sets of resetting shape memory alloy wires 8 pass through the resetting wire holes 17 of the left moving piston 6 and the right moving piston 11 , are tensioned and fixed on the left moving piston 6 and the right moving piston 11 with clamps 16 . Two groups of energy-dissipating shape-memory alloy wires 9 on the left pass through the energy-dissipating wire holes 18 of the left cylinder head 1 and the left movable piston 6, left fixed piston 7 and right fixed piston 10, and their left ends are fixed on the left cylinder head 1. On the adjusting screw rod 3, the right end is fixed on the right fixed piston 10. Two groups of energy-dissipating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com