Plastic composite board with friction-welding structure

A welding structure and friction welding technology, which is applied in the direction of sheet/board, synthetic resin layered products, building components, etc., can solve the problems of difficulty in production, difficulty in making large-sized boards, inconvenient movement, etc., to increase the appearance Effect, high surface hardness, effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

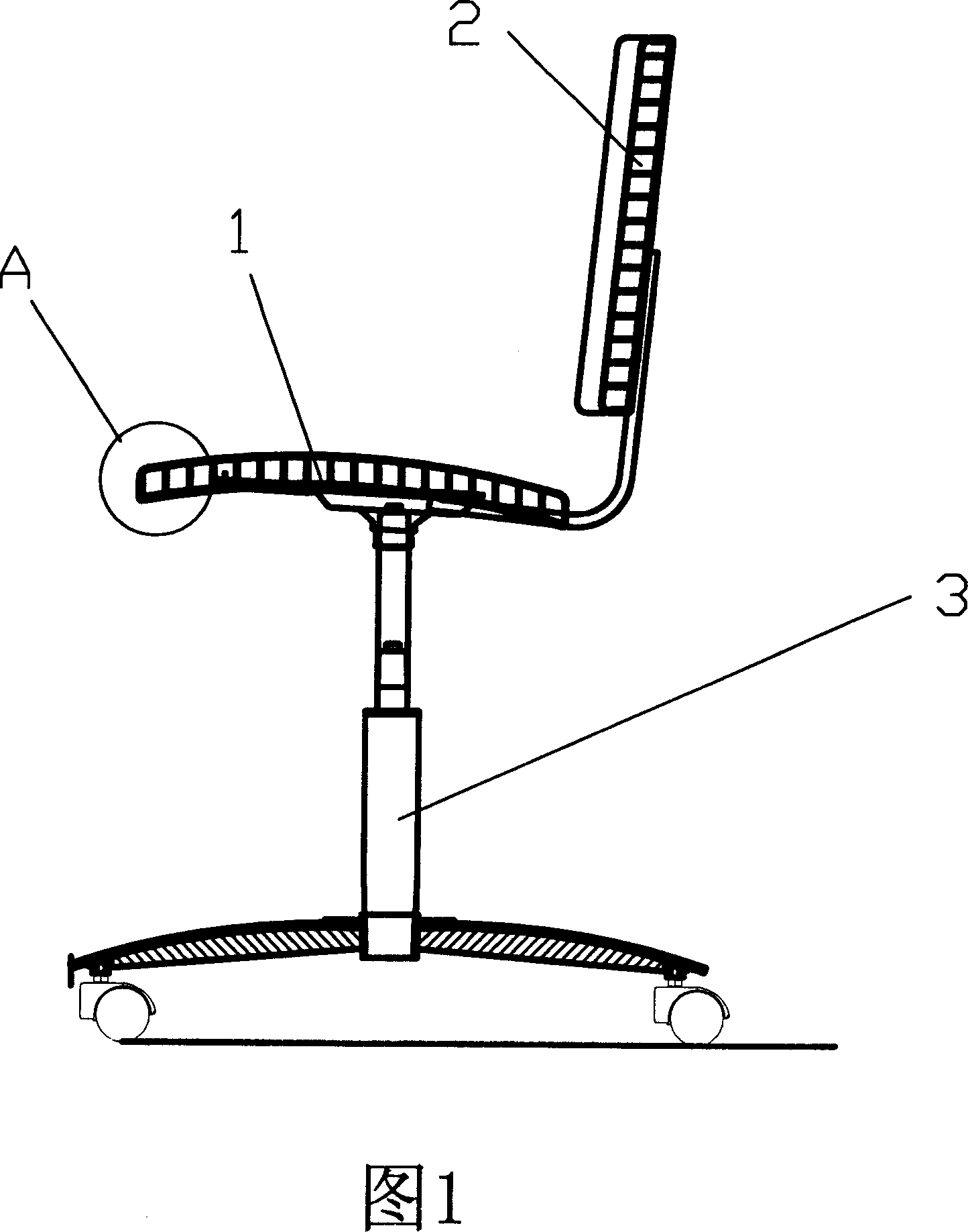

[0049] Embodiment 1, referring to Fig. 1 to Fig. 7, a plastic composite plate with a friction welding structure of the present invention is used on a seat. Fig. 1 shows a schematic structural view of a seat, the seat It includes a chair frame 3, a chair board 1 and a chair back 2 mounted on the chair frame 3, and the chair board 1 and the chair back 2 are plastic composite boards with a friction welding structure.

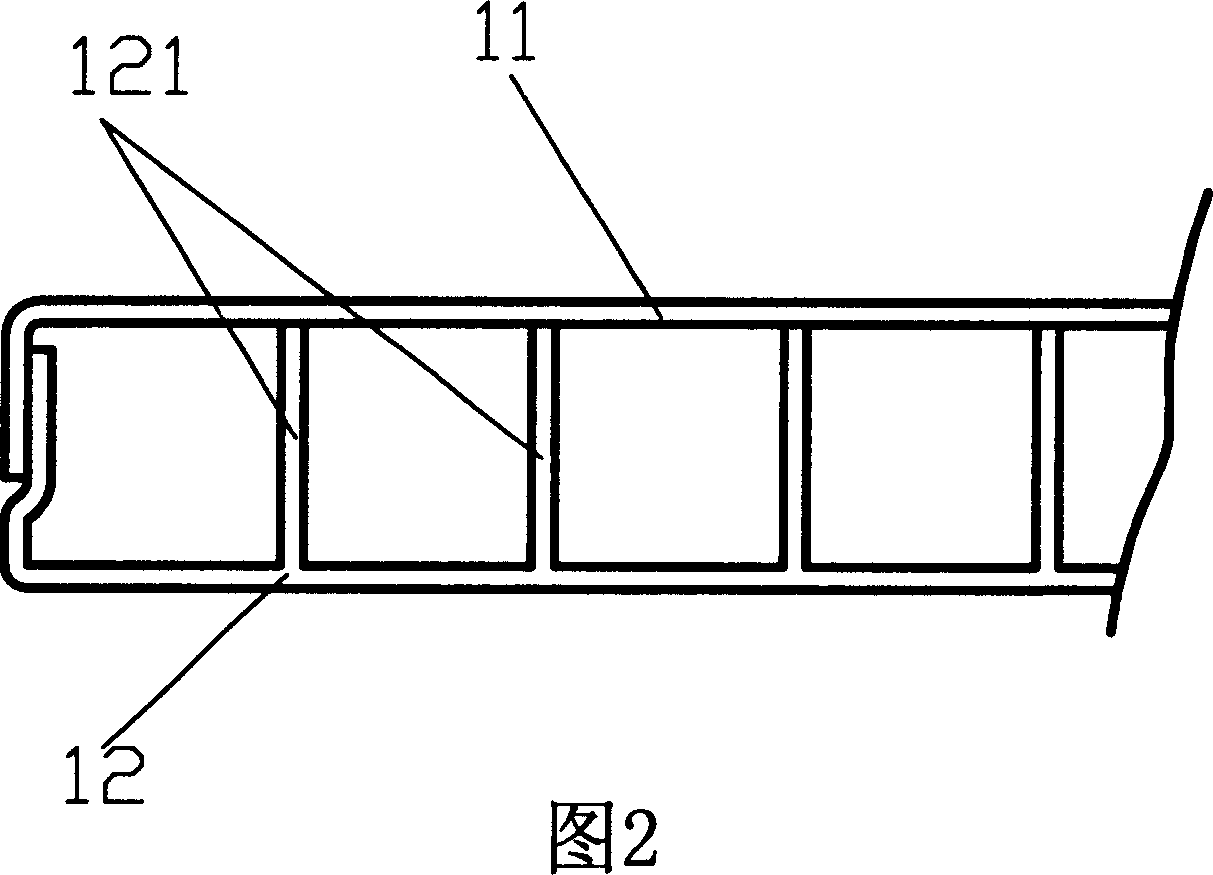

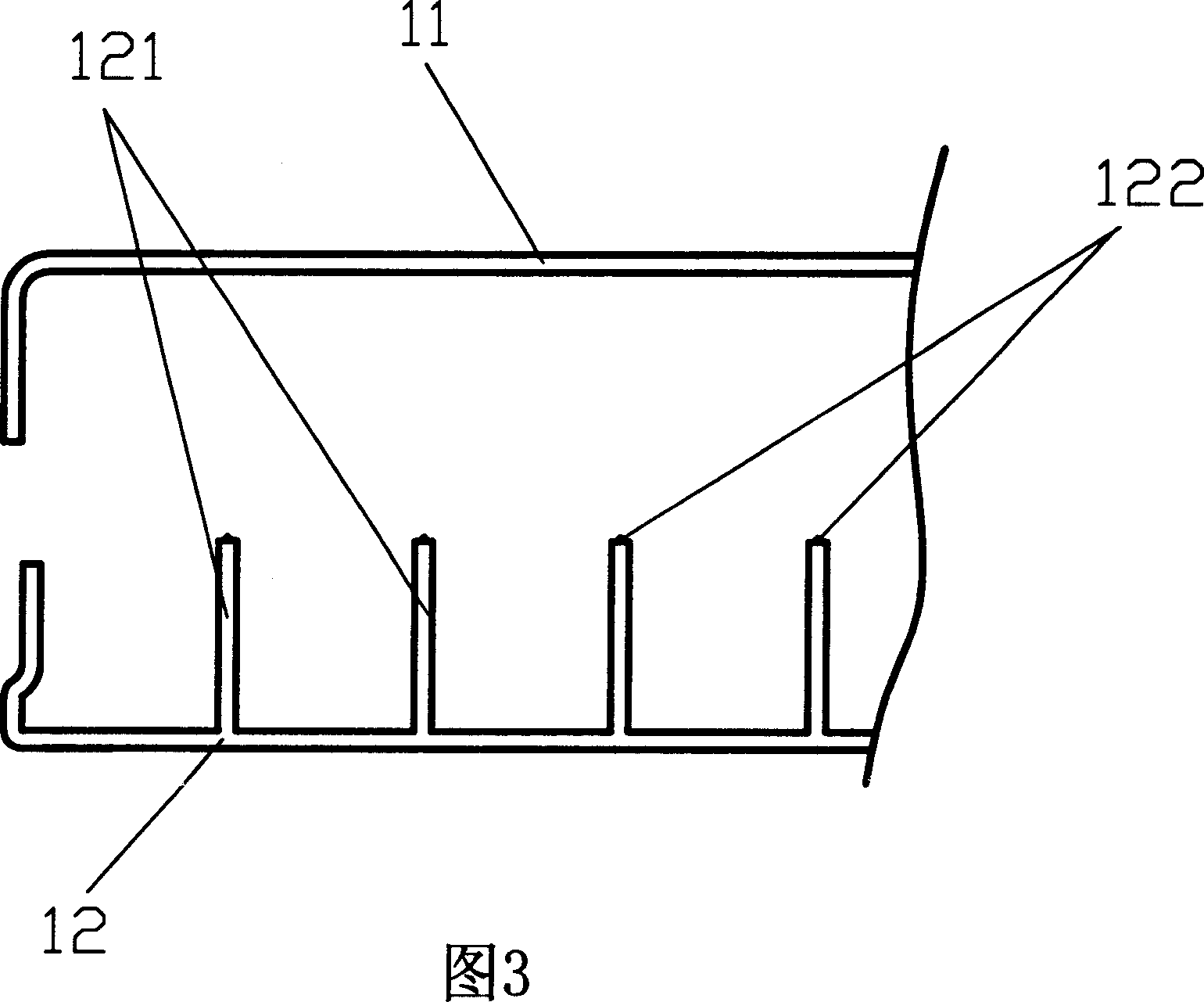

[0050] As shown in Figures 2 to 5, the chair board 1 includes:

[0051] The plastic panel 11 is a monomer structure with a certain shape made by direct extrusion molding or extrusion molding, and has an upper surface and a lower surface;

[0052] The injection molded part 12 is a single structure made by direct injection molding and matched to the shape of the plastic panel. Its upper part is integrally injection-molded with several upwardly protruding ribs 121. The top of the ribs 121 is connected with the bottom of the plastic panel 11. There are several small p...

Embodiment 2

[0060] Embodiment 2, as shown in FIG. 8, a plastic composite board with a friction welding structure of the present invention is used on a seat. The difference from Embodiment 1 is that the surface of the panel is provided with a printing layer 112, The printing layer 112 is a texture or pattern structure directly printed on the surface of the panel by printing.

Embodiment 3

[0061] Embodiment 3, as shown in Fig. 9 to Fig. 10, a plastic composite plate with a friction welding structure of the present invention is used on a seat. Fig. 9 shows a structural schematic diagram of another structural seat, which The seat comprises a chair frame 30, a chair board 10 and a chair back 20 mounted on the chair frame 30, and the chair board 10 and the chair back 20 are plastic composite plates of friction welding structure.

[0062] Among them, the chair board 10 includes a plastic panel 15, an injection molded part 16 and an embedded reinforcement 17; the plastic panel 15 is a single structure with a certain shape made by direct extrusion molding or extrusion molding. surface and lower surface; the upper part of both sides of the injection molded part 16 is integrally injection-molded with several upwardly protruding ribs 161, and the top of the ribs 161 is provided with small convex lines or small bumps (not shown in the figure), and the plastic panel 15 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap