GaN-based vertical LED power chip with current extending layer and barrier and its production

A technology of current expansion layer and power chip, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., and can solve the problems of large thermal resistance of LED chips, inability to make full use of light-emitting layer materials, and low heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

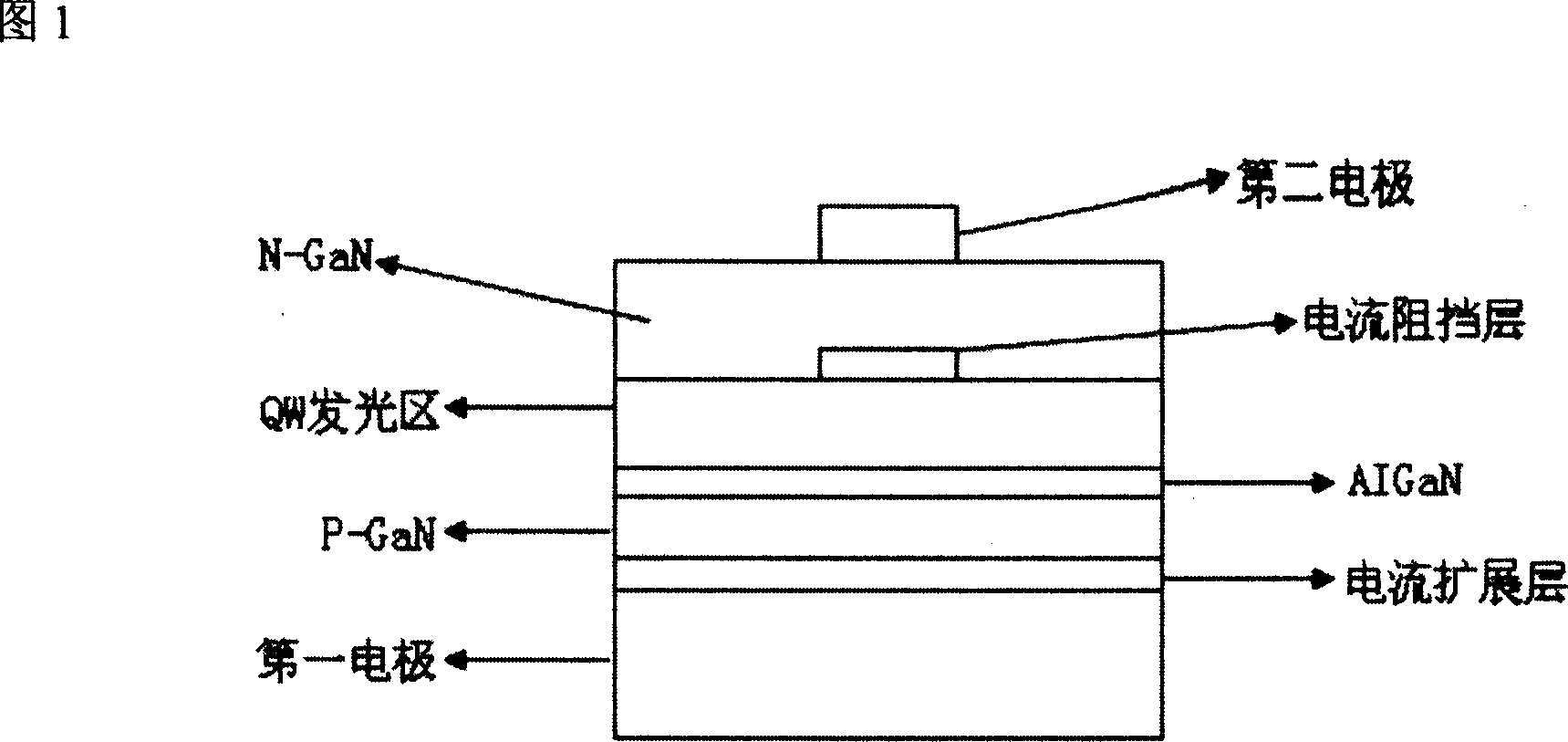

[0008] As shown in Figure 1, the GaN-based vertical LED power chip with a current spreading layer and a blocking layer of the present invention is composed of a first electrode, a current spreading layer, a GaN-based LED epitaxial light-emitting layer, a current blocking layer and a second electrode;

[0009] The GaN epitaxial layer includes an N-GaN layer, a light emitting layer and a P-GaN layer.

[0010] For general high-power flip-chip components, the two electrodes are on the same side of the GaN epitaxial layer / sapphire growth substrate. Due to the high resistivity of the P-GaN layer, the current cannot be distributed uniformly and most of the current will be confined under its electrodes. In addition, current congestion occurs when current flows downward through the P-type layer and then to the light-emitting layer to generate light, and then passes through the N-type layer and is localized around the N electrode.

[0011] The GaN high-power flip-chip structure with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com