Process for manufacturing passiflora edulis fruit juice beverage

A manufacturing method, the technology of passion fruit, applied in the direction of food science, etc., can solve the problems of difficult processing methods, achieve the effects of stable complementarity, reduction of flavor loss, and improvement of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

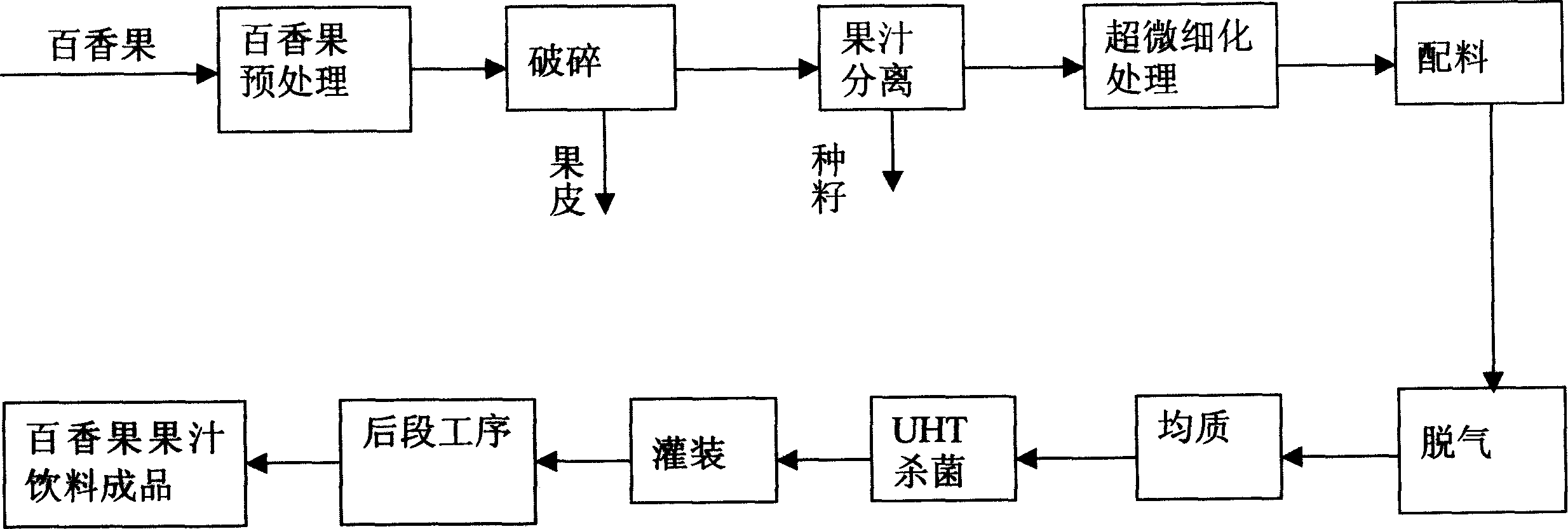

[0037] A manufacturing method of passion fruit juice beverage, its technological process includes the following steps:

[0038] A. Pretreatment of grading and cleaning passion fruit:

[0039] Select the passion fruit that meets the requirements after three levels of cleaning, the first level: high-pressure water surfing rinse, the second level: brush scrubbing, and the third level: pure water rinse;

[0040] B. Crushing: The clean passion fruit after the pretreatment is crushed with a roller-type fruit cold pressing equipment to break the peel, and separate the pulp, pulp and peel;

[0041] C. Juice separation:

[0042] ① Beating: the pulp and fruit pulp are processed by a brush-type peeling machine and a beating machine equipped with a "neoprene rubber" impeller.

[0043] ②Overhead sieve: filter the beating juice through a stainless steel screen with 0.8mm holes to obtain filtrate I,

[0044] ③Fine filtration: filter the filtrate I through a 60-80 mesh stainless steel screen to r...

Embodiment 2 Embodiment 6

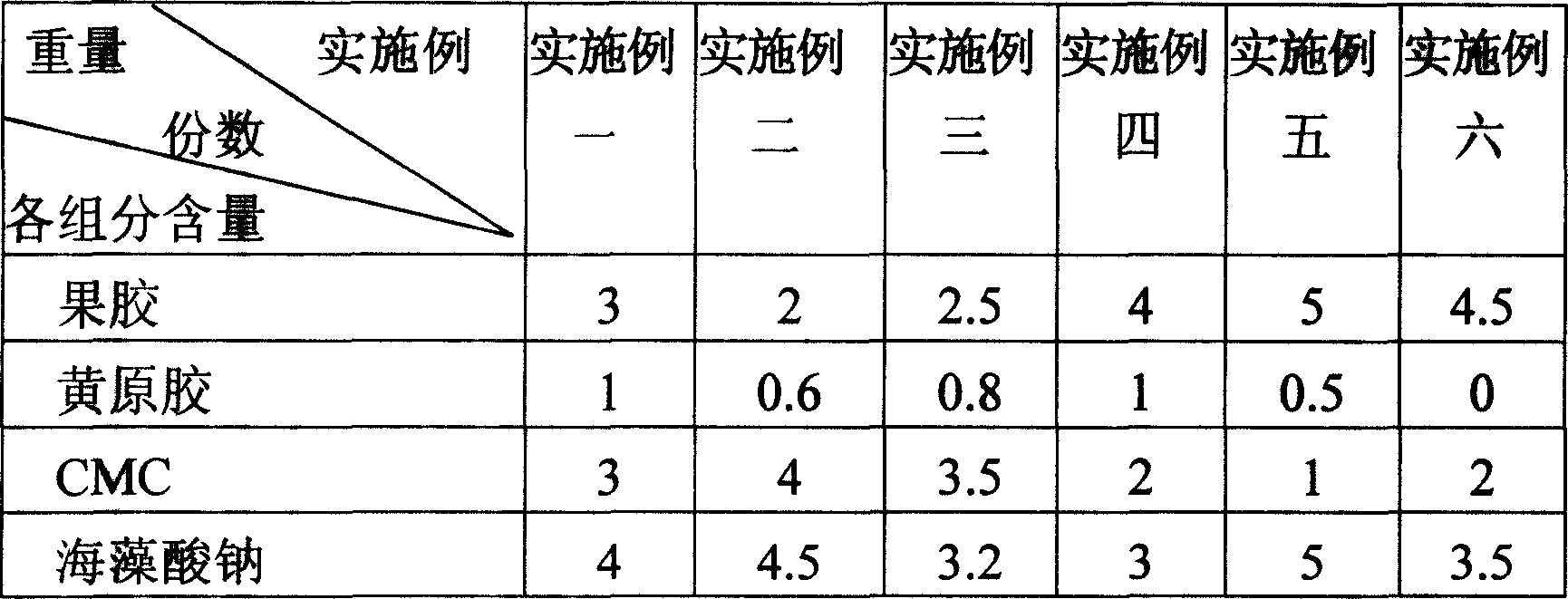

[0060] A method for manufacturing a passion fruit juice beverage. The process flow steps are the same as those in Example 1. The difference is that the mixed stabilizer contains a combination of pectin and xanthan gum, sodium carboxymethyl cellulose, and sodium alginate. The ratio is different, the content of each component (refer to the attached table) is calculated in parts by weight:

[0061] Pectin 2~5 parts by weight

[0062] Xanthan gum 0~1 parts by weight

[0063] Sodium carboxymethyl cellulose 1~4 parts by weight

[0064] 3 to 5 parts by weight of sodium alginate.

[0065]As a variation of the embodiments of the present invention, the stabilizer in the first-stage compounding process may not use a mixed stabilizer, but only one of the above-mentioned stabilizers, but its stabilizing effect is deteriorated.

[0066] Attached table: List of contents of each component in mixed stabilizer

[0067] ——Calculated in parts by weight

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com